Slurry Bed Reaction Process for Aromatic Alkylation

A technology for alkylation and alkylation reaction of aromatic hydrocarbons, applied in chemical instruments and methods, organic chemistry, molecular sieve catalysts, etc., can solve problems such as serious side reactions of alkylation, low utilization rate of methanol, poor catalyst stability, etc., and achieve The effect of reducing reaction temperature rise, suppressing side reactions, and promoting heat transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

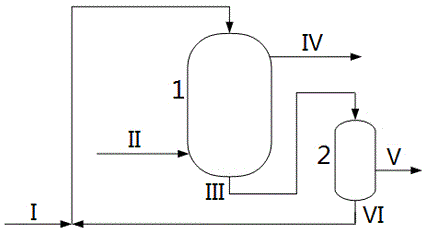

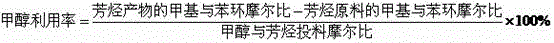

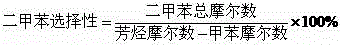

[0027] in such as figure 1 In the reaction device shown, the geometric volume of the reactor is 10L, and the charging coefficient is 0.6. Toluene is used as the raw material of aromatic hydrocarbons, methanol is used as the alkylation reagent, and hydrogen is used as the circulating carrier gas. shape-selective methylation catalyst content for the alkylation reaction. Two hours after the reaction ran smoothly, samples were taken for analysis. The specific evaluation conditions and data results are listed in Table 1. The xylene selectivity in Table 1 refers to the ratio of xylene products in all aromatic products.

[0028] Table 1

[0029]

Embodiment 2

[0031] in such as figure 1 In the shown reaction device, the geometric volume of the reactor is 10L, and the charging coefficient is 0.6. Toluene is used as the aromatic hydrocarbon raw material, and methanol is used as the alkylation reagent. Alkylation reaction was carried out by changing the type of circulating carrier gas. Two hours after the reaction ran smoothly, samples were taken for analysis. The specific evaluation conditions and data results are listed in Table 2. The calculation method of each performance index is the same as Example 1.

[0032]Table 2

[0033]

Embodiment 3

[0035] in such as figure 1 In the reaction device shown, the geometric volume of the reactor is 10L, and the filling coefficient is 0.6. Toluene is used as the raw material of aromatic hydrocarbons, methanol is used as the alkylation reagent, and hydrogen is used as the circulating carrier gas. 5000g of toluene and 125g of shape-selective Methylation catalyst, change the ratio of toluene and methanol for alkylation reaction. Two hours after the reaction ran smoothly, samples were taken for analysis. The specific evaluation conditions and data results are listed in Table 3. The calculation method of each performance index is the same as Example 1.

[0036] table 3

[0037]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com