Mining excavator lifting mechanism

A technology for excavators and mines, which is applied in the field of hoisting mechanisms and hoisting mechanisms of mining excavators. It can solve the problems of complicated electrical control process, cumbersome assembly work, and heavy equipment weight, and achieve the reduction of electrical detection components and failure points. Simple, low-cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

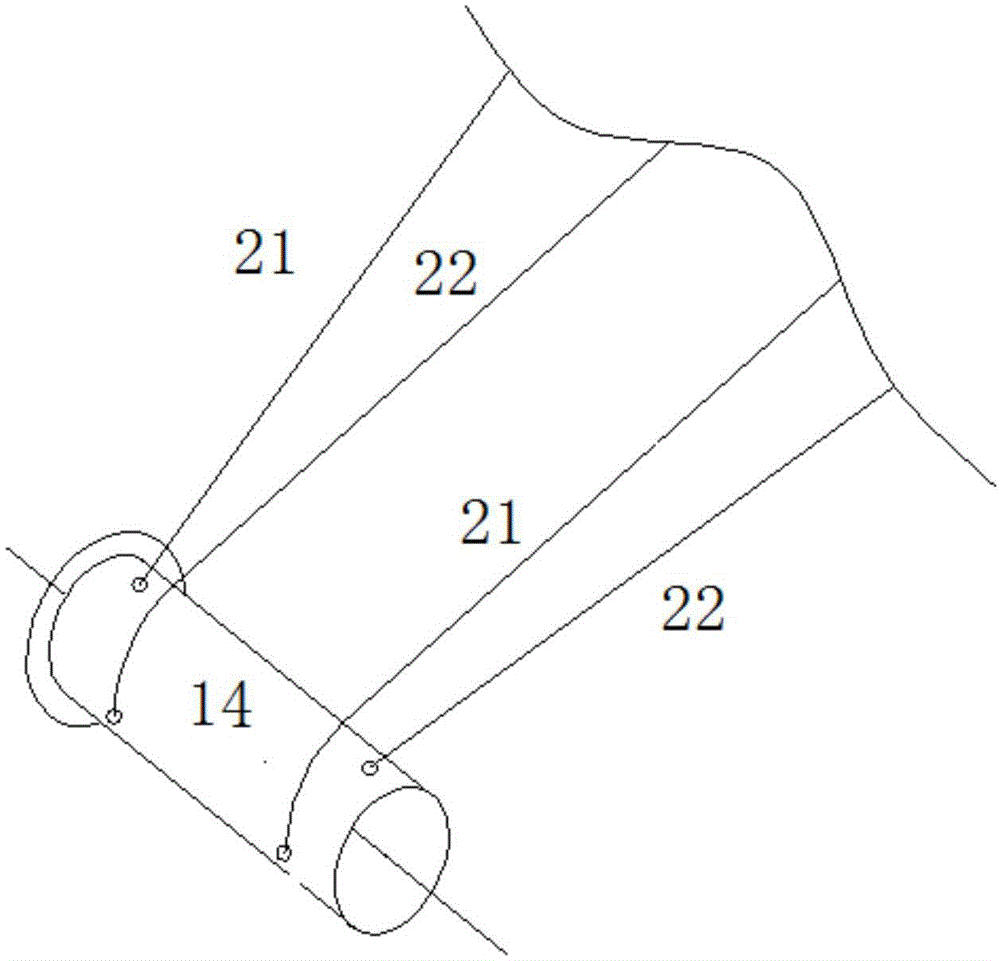

Image

Examples

Embodiment 1

[0024] see figure 1 , a mining excavator lifting mechanism, including: a first-stage deceleration transmission mechanism, a second-stage deceleration transmission mechanism, a motor 18, the non-load end of the motor 18 is equipped with a brake 17, and the load end is connected to the first stage through the coupling 19. Step reduction transmission mechanism connection, in which:

[0025] The first-stage deceleration transmission mechanism includes: a shaft gear 4 and a large gear 9. The shaft gear 4 is installed in the bearing seat of the gearbox 1 through a bearing, and the large gear 9 is installed on the gear shaft 8 through a flat key and meshes with the shaft gear 4;

[0026] The second-stage deceleration transmission mechanism includes: the gear shaft 8 installed in the bearing seat of the gearbox 1 through the bearing, the reel large gear 12, the reel shaft 13, and one end of the reel shaft 13 is installed on the bearing of the gearbox 1 through the bearing. Inside the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com