Arrangement structure for elevator without machine room

A technology of machine room-less elevators and layout structure, which is applied to elevators in buildings, lifting equipment in mines, transportation and packaging, etc. The effect of reducing occupancy, lowering elevator costs and building costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

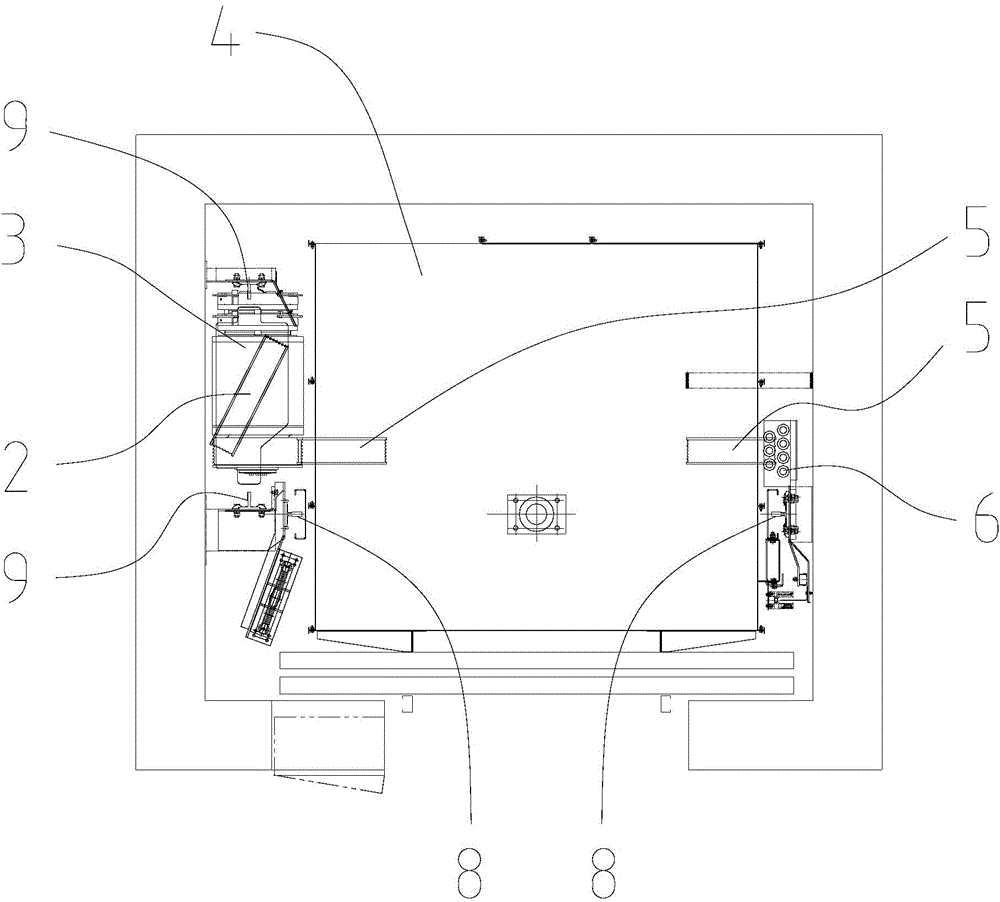

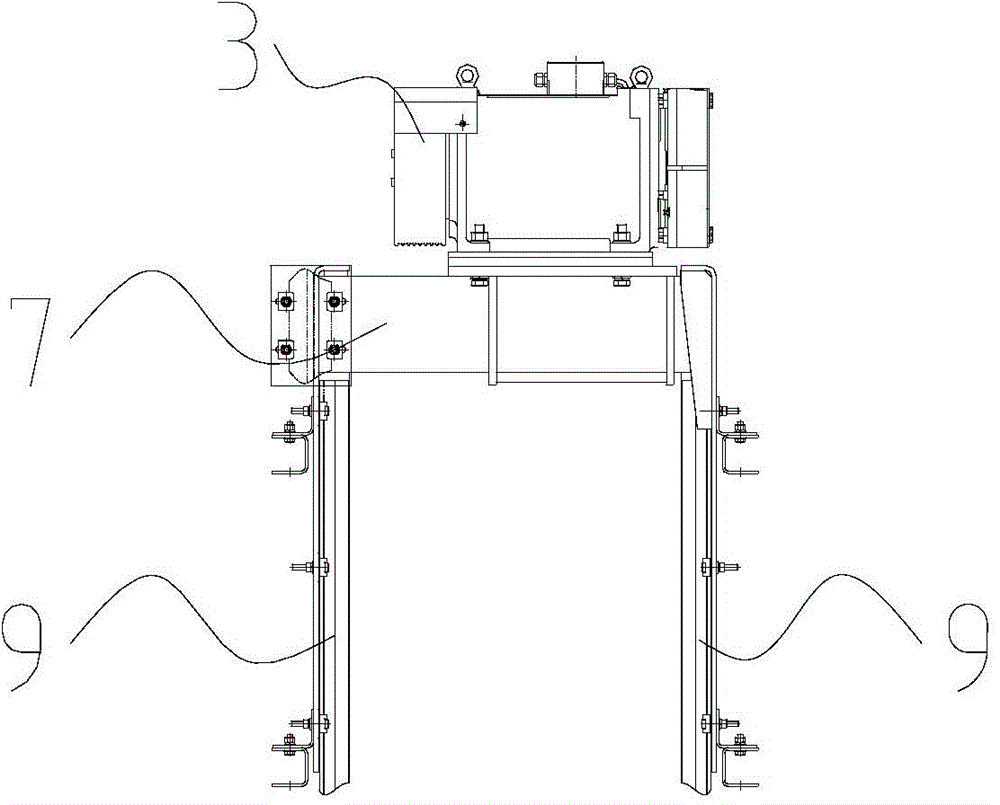

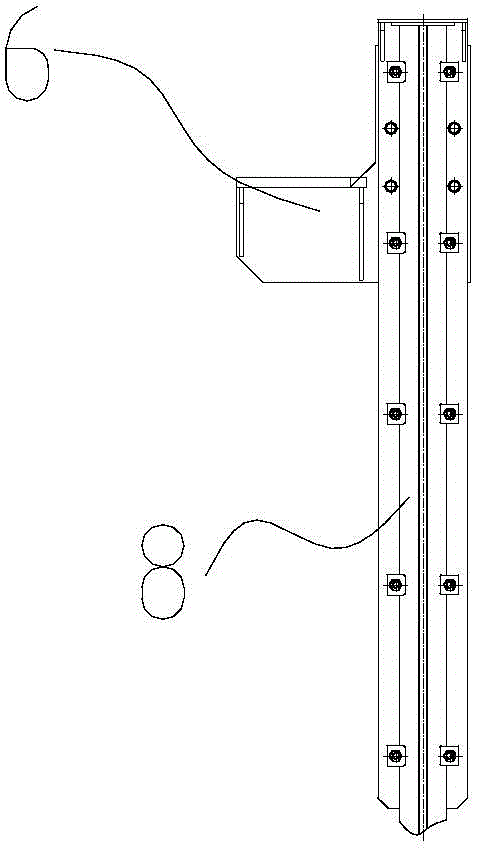

[0022] see Figure 1 to Figure 6 , an arrangement structure of an elevator without a machine room, which includes a counterweight 1, a counterweight sheave 2 mounted on the counterweight 1, a traction machine 3, a car 4, and a car mounted on the car 4 Car reverse sheave 5, car rope head plate assembly 6, traction frame 7 supporting traction machine 3, car guide rail 8 for guiding the car 4 to run up and down, counterweight 1 to guide the up and down movement of the counterweight Heavy guide rail 9, steel wire rope 10.

[0023] The counterweight 1 and the traction machine 3 are located on the same side of the car 4, the counterweight guide rails 9 are a pair, the pair of counterweight guide rails 9 are located on the same side of the car 4, the traction machine frame 7 is erected on a pair of counterweights between rails 9, such as figure 2 shown. In this embodiment, the counterweight 1 and the traction machine 3 are located on the left side of the car 4, a pair of counterw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com