Car Progressive Booster Safety Bar

A safety bumper and automobile technology, applied to bumpers and other directions, can solve the problems of limited bumper deformation, cushioning the inertia of the car, and not being able to protect life safety well, so as to achieve the effect of not being easy to hurt people and having a good buffering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below in conjunction with accompanying drawing and embodiment the technical solution of the present invention is further described:

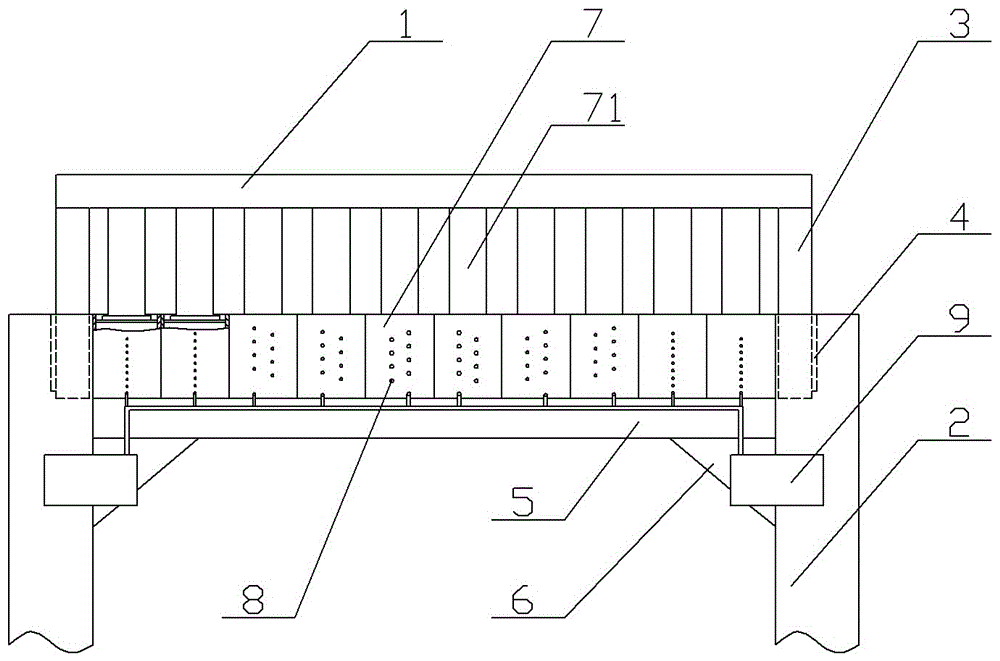

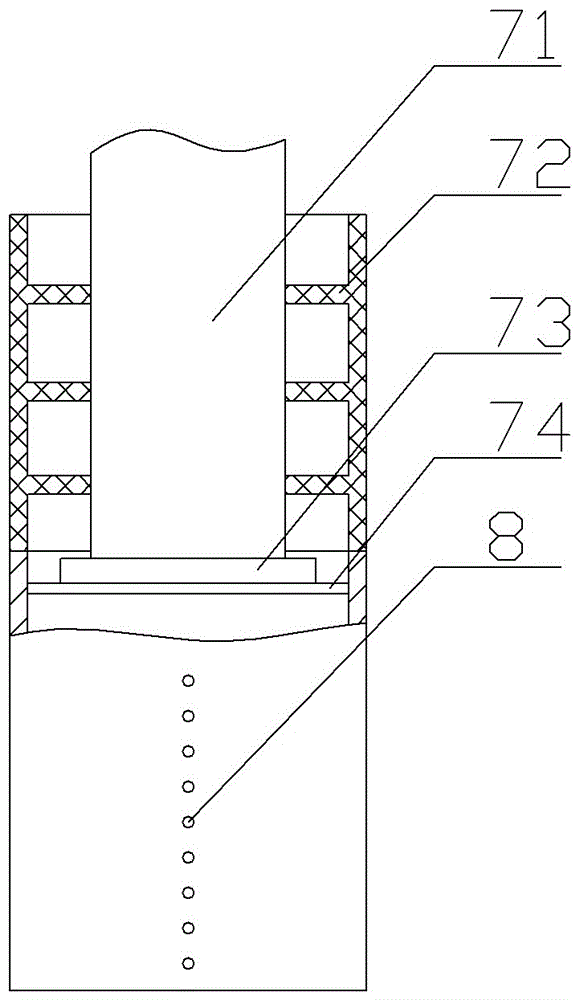

[0015] like figure 1 As shown, the present invention provides a progressive booster bumper for automobiles, including a front bumper 1 arranged in front of the chassis frame. The front bumper 1 can be a common sheet metal bumper. Of course, ordinary channel steel can also be used instead. The front bumper 1 and the chassis frame 2 are on the same plane, and the direction is vertical. The two ends of the front bumper 1 are also welded with guide rods 3 respectively. The guide rods 3 can be round pipes or It is a square tube, and the guide rod 3 slides forward and backward with the chassis frame 2. At this time, one end of the sliding sleeve 4 needs to be welded inside the chassis frame 2 to better guide the guide rod 3. The chassis frame 2 is also welded and fixed with the front safety The rear of the horizontal support bar 5 parallel to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com