Pneumatic tires

A technology for pneumatic tires and tires, which is applied to tire parts, tire treads/tread patterns, transportation and packaging, etc. It can solve the problems of reduced area, poor wear resistance, and reduced rigidity of the tread portion, and achieves lateral Effects of increased partial stiffness, improved wear resistance, and improved rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

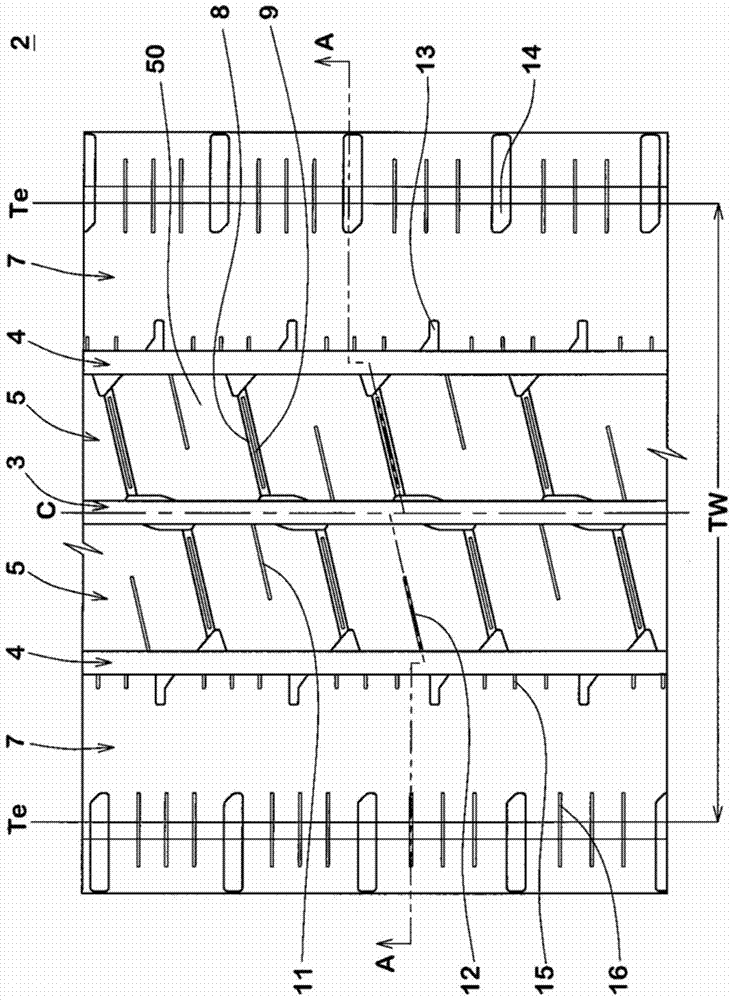

[0059] Prototype has figure 1 The tread pattern is based on the pneumatic tires for light trucks with a size of 185 / 65R15 based on the specifications in Table 1, and the test is based on the wear resistance and wet road performance of the actual vehicle. The evaluation method is as follows.

[0060]

[0061] The test tire mounted on the rim of 15×5.0J was installed on the front wheel of a 2-D 2-ton loading vehicle (nuclear load) under the condition of an internal pressure of 600kPa, and the amount of wear after driving 8000km was measured to confirm the general situation of tire shoulder wear. The results are represented by an index with Example 5 being 100, and the larger the numerical value, the better the wear resistance.

[0062]

[0063] The above-mentioned vehicle was transported on a wet asphalt road surface having a water film with a thickness of 5 mm, and the driver's senses were used to evaluate characteristics such as rigidity and grip when cornering at a speed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com