Detection device, three-dimensional printer and three-dimensional printing method

A technology of 3D printer and detection device, which is used in optical device exploration, additive processing, etc., can solve problems such as extrusion molding materials, slippage, and reduce the printing quality of 3D objects, and achieve the effect of preventing empty printing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

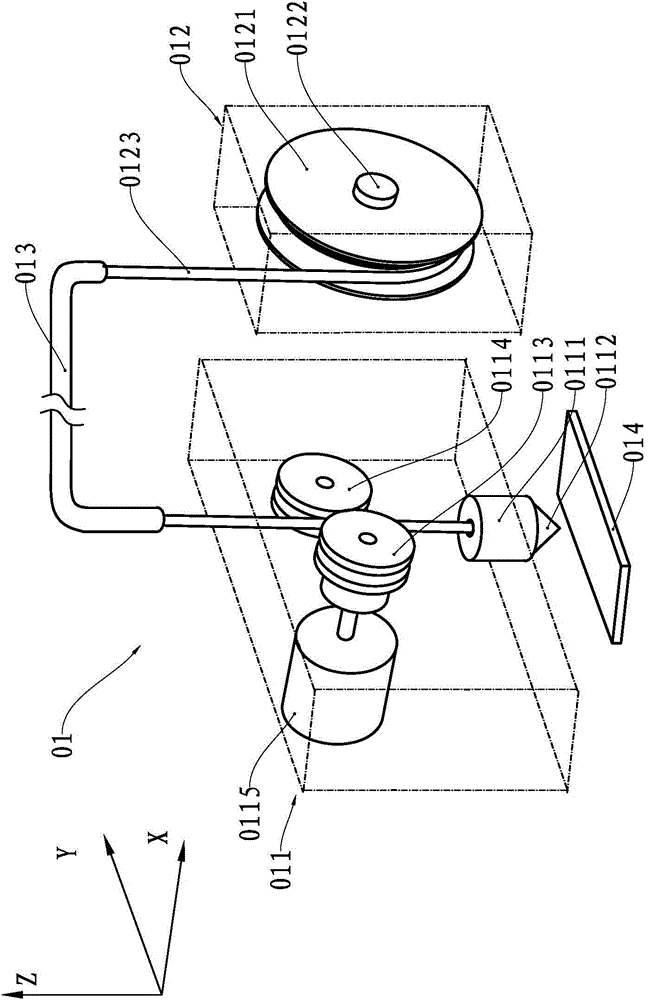

[0032] The first embodiment of detection device, three-dimensional printer and three-dimensional printing method

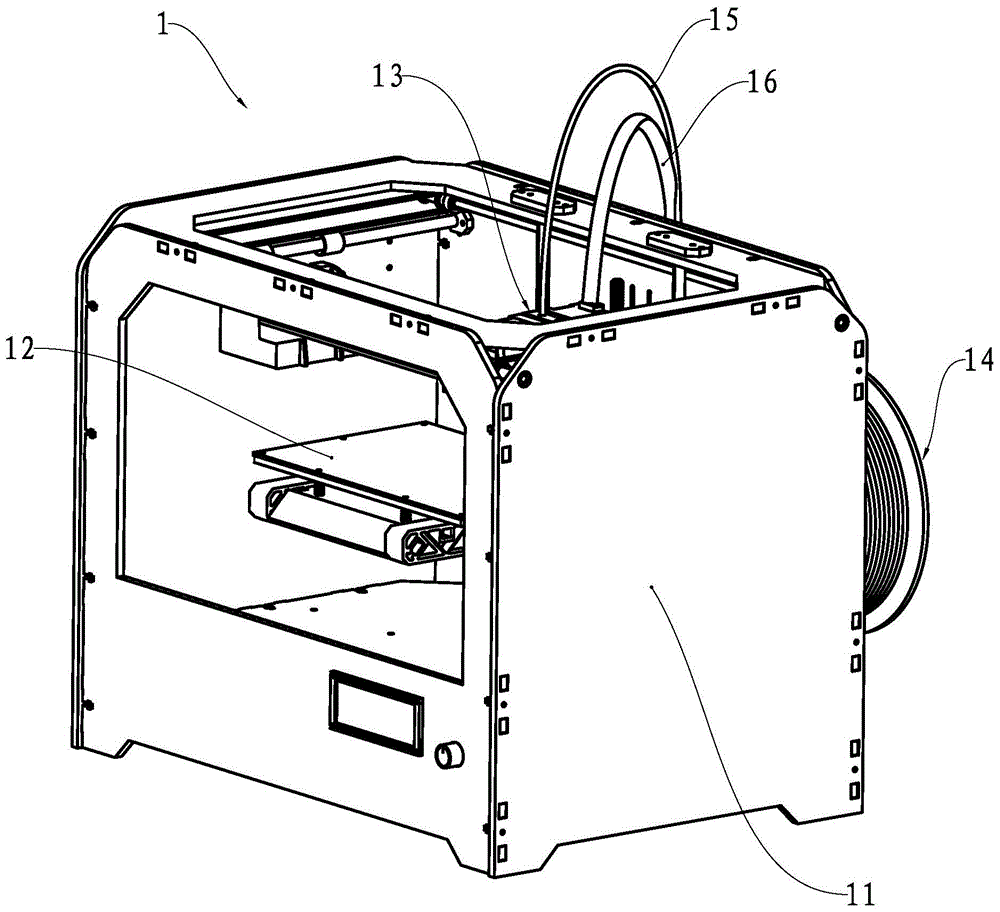

[0033] see figure 2 , the three-dimensional printer 1 has a housing 11 and a stage 12 mounted on the housing 11 , a printing head 13 , a feeding device 14 , a detection device and a control unit. The molding filament of the feeding device 14 is supplied to the print head 13 through the hose 15 , and the control unit is electrically connected with the electrical components on the print head 13 through the control line 16 .

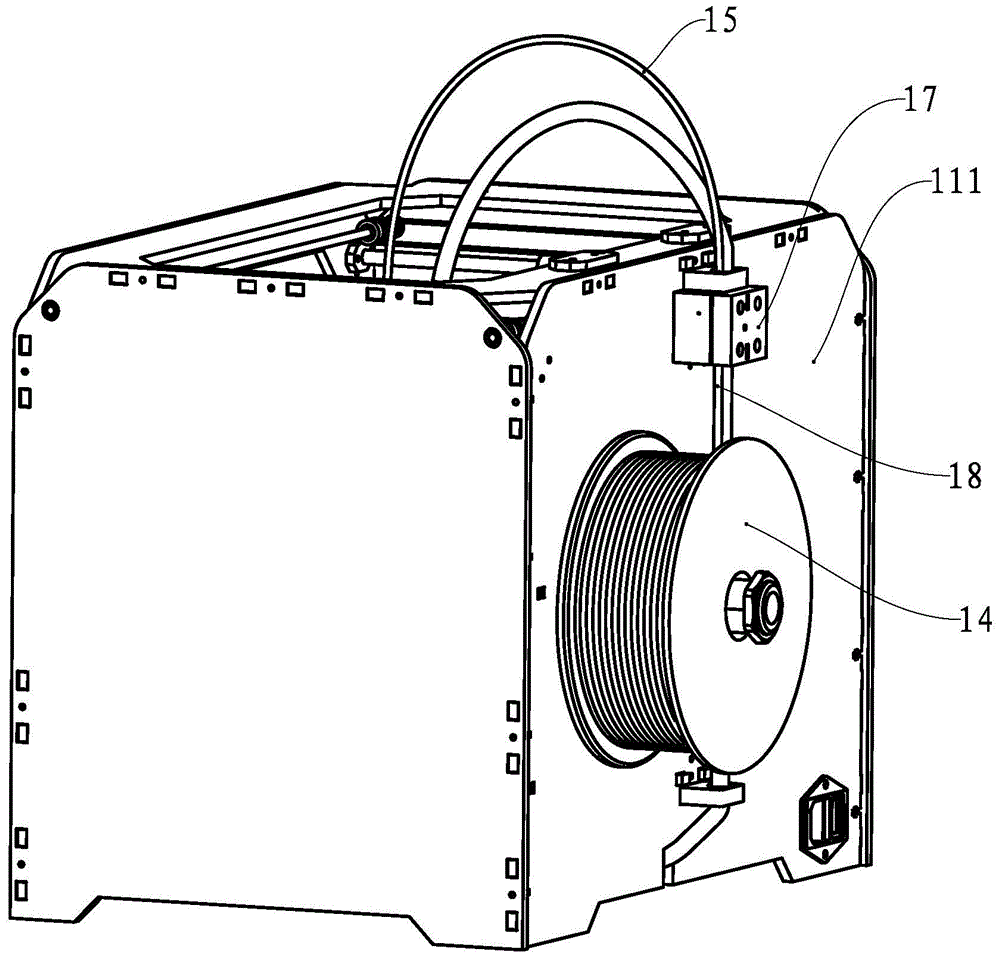

[0034] see image 3 , the detection device 17 is installed on the rear plate 111 of the housing 11, the molding wire of the feeding device 14 enters the detection device 17 through the guidance of the hose 18, and enters the print head 13 under the guidance of the hose 15 after passing through the detection device 17, That is, the detection device 17 is located upstream of the printing head 13 in the direction of travel of the forming filame...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com