Flexible six-shaft robot

A six-axis robot and flexible technology, applied in the field of robotics, can solve the problems of limited application site and scope of use, increased robot cost, and increased design size, and achieve the effects of reducing weight, increasing bearing capacity, and reducing volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail;

[0026] Such as figure 1 , 2 , 3, 4, 5, 6, a flexible six-axis robot, including a chassis, also includes:

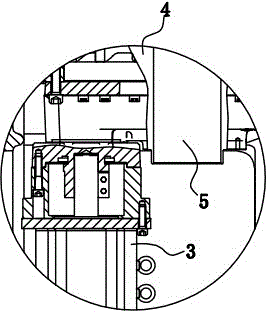

[0027] The first shaft system 1 includes a first servo motor 3 arranged in the chassis 2, and a first reducer 4 matched with the first servo motor 3, and the first reducer 4 communicates with the first shaft 5 through the first shaft. The rotating base 6 is rotatingly connected;

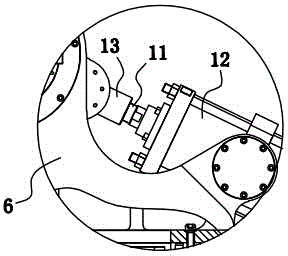

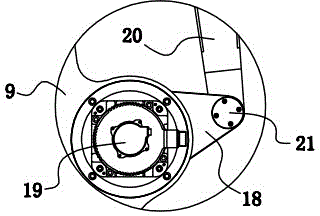

[0028] The second shaft system 7 includes a second servo motor 8 arranged on the first rotating base 6, and the first rotating base 6 is connected with a second rotating arm 9 that rotates with the second servo motor 8; An auxiliary supporting device 10 for supporting the second rotating arm 9 is arranged on the rotating base 6 . The auxiliary supporting device 10 includes a cylinder 12 with a piston rod 11 , and the piston rod 11 is rotatably connected to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com