Multi-freedom degree wheeled mobile stacking robot

A technology of moving codes and degrees of freedom, applied in the field of robots, can solve the problems of large required torque, small working space, low rigidity, etc., and achieve the effect of reducing dynamic torque, improving working space and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

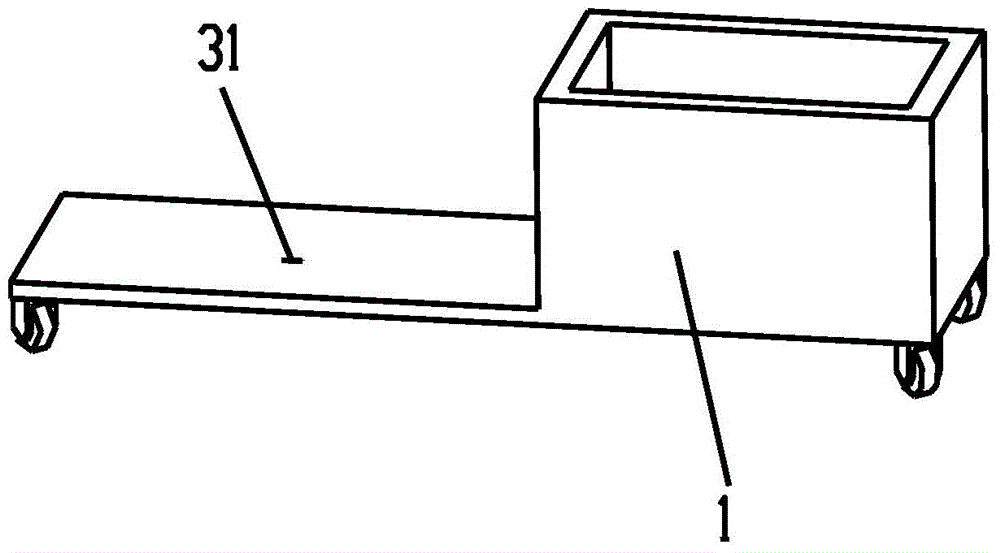

[0037] A multi-degree-of-freedom wheeled mobile palletizing robot, comprising a movable platform 1, a body 2, a first connecting rod 3, a second connecting rod 5, a third connecting rod 24, a fourth connecting rod 20, and a fifth connecting rod 22. Sixth connecting rod 39, seventh connecting rod 38, eighth connecting rod 18, ninth connecting rod 11, tenth connecting rod 16, eleventh connecting rod 13, twelfth connecting rod 14, thirteenth connecting rod Rod 25, fourteenth connecting rod 26, fifteenth connecting rod 28, sixteenth connecting rod 40, seventeenth connecting rod 41, eighteenth connecting rod 42 and end effector 30;

[0038] The eighth connecting rod 18 is in the shape of a "T", and a first connecting end 181, a third connecting end 183, a fourth connecting end 184 and a fifth connecting end 185 are respectively pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com