Tin soldering tooling for heat radiation by utilizing wave-shaped heat radiation hole and heat conducting holes

A heat conduction hole and wave-shaped technology, which is applied in the field of inductor auxiliary tools, can solve the problems of reducing work efficiency and achieve the effects of improving soldering efficiency, prolonging the life of tooling, and facilitating regular cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in detail below with reference to the accompanying drawings and examples.

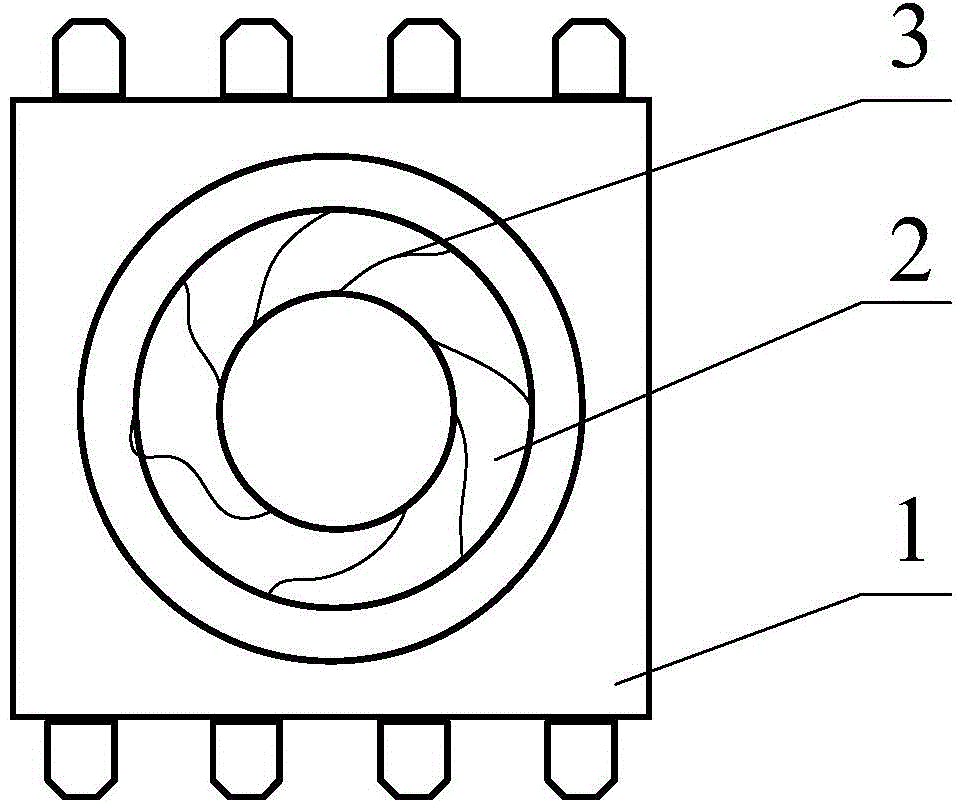

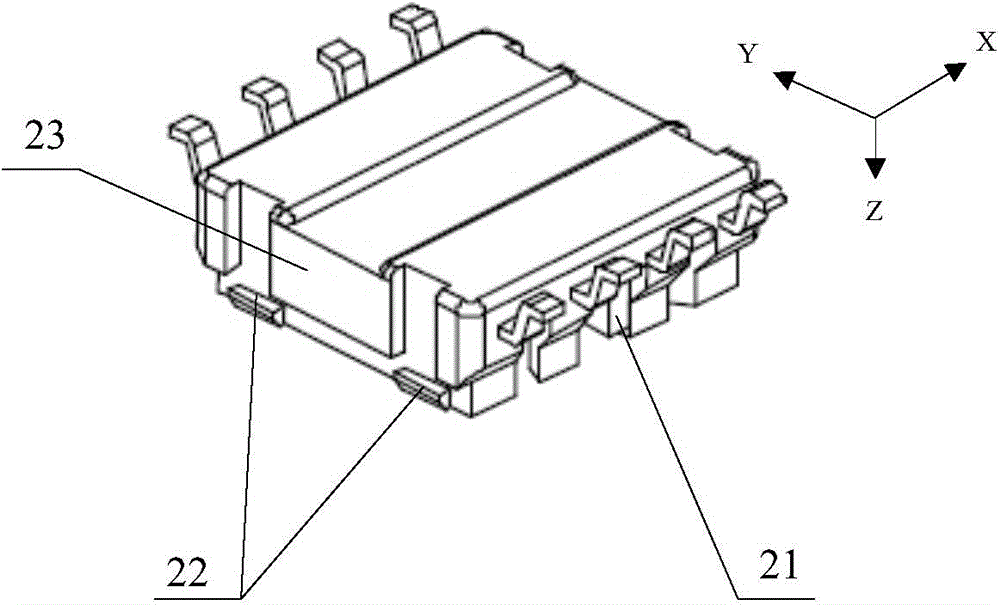

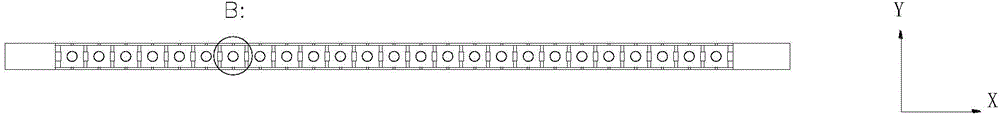

[0030] The present invention provides a soldering tooling for an automatic soldering system for inductors. As shown in the figure, the base 201 of the soldering tooling is a strip-shaped aluminum alloy plate. For the convenience of description, the extension of the strip-shaped aluminum alloy plate is set The direction is the X direction, the plate thickness direction is the Y direction, and the plate width direction is the Z direction.

[0031] There is a through groove on one of the long sides of the strip-shaped aluminum alloy plate, and inverted T-shaped support platforms 203 are arranged at equal intervals in the groove, and the support platform is also a partition between two adjacent inductors. It is a plate-like structure, T-shaped from the side view. The height of the support platform is the same as the depth of the groove.

[0032] As shown in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com