Vertical and horizontal dual-purpose steel ladle tilting mechanism

A technology of vertical and horizontal dual-purpose, tipping mechanism, which is applied in casting melt containers, metal processing equipment, casting equipment, etc. Effects of normal production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

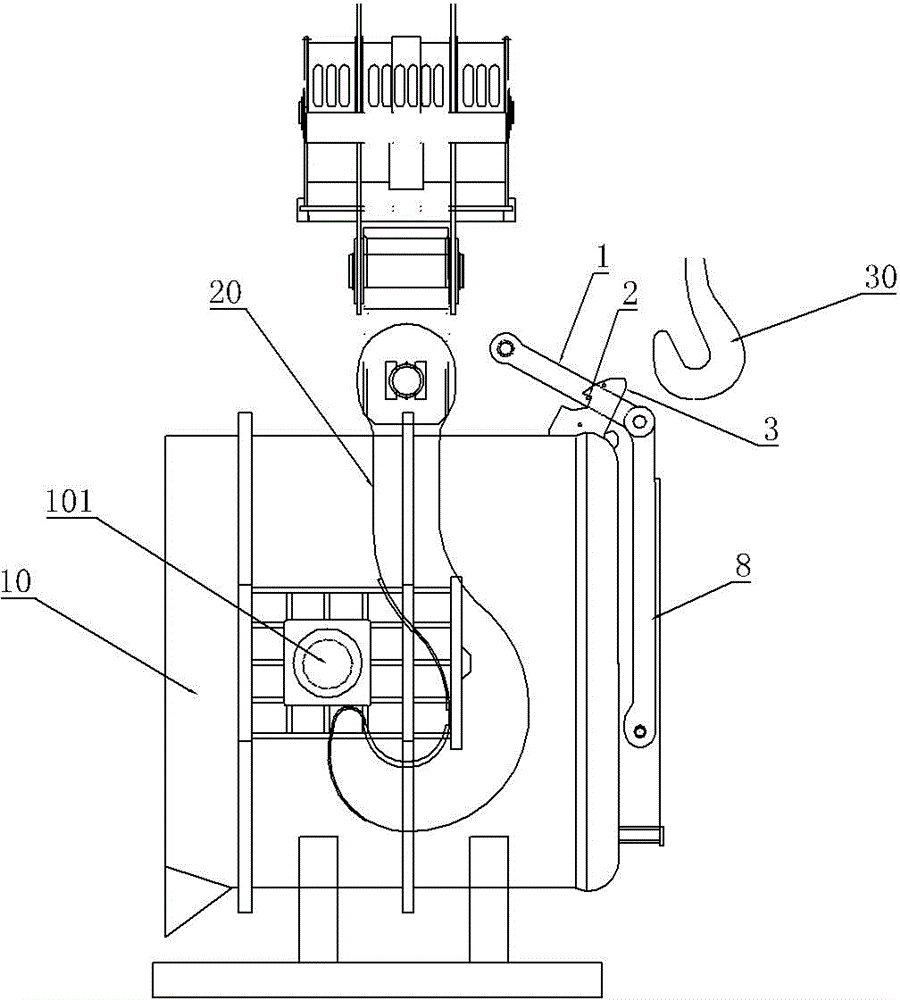

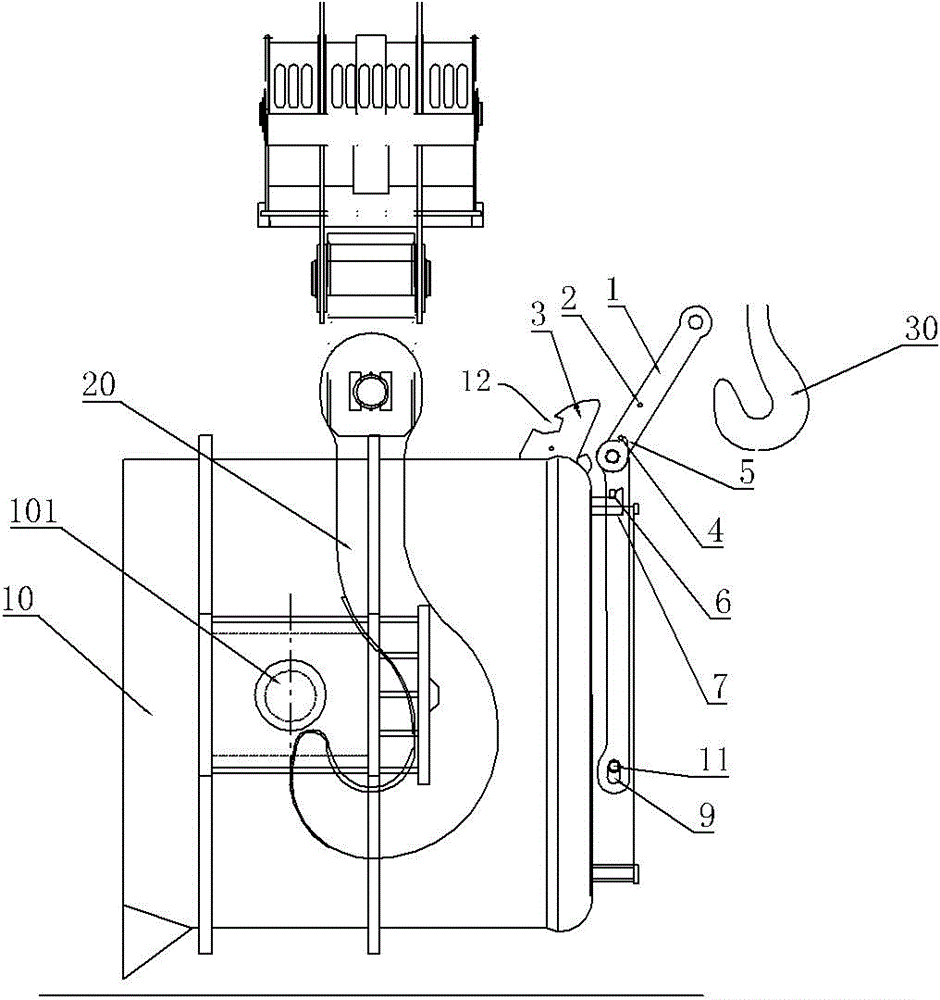

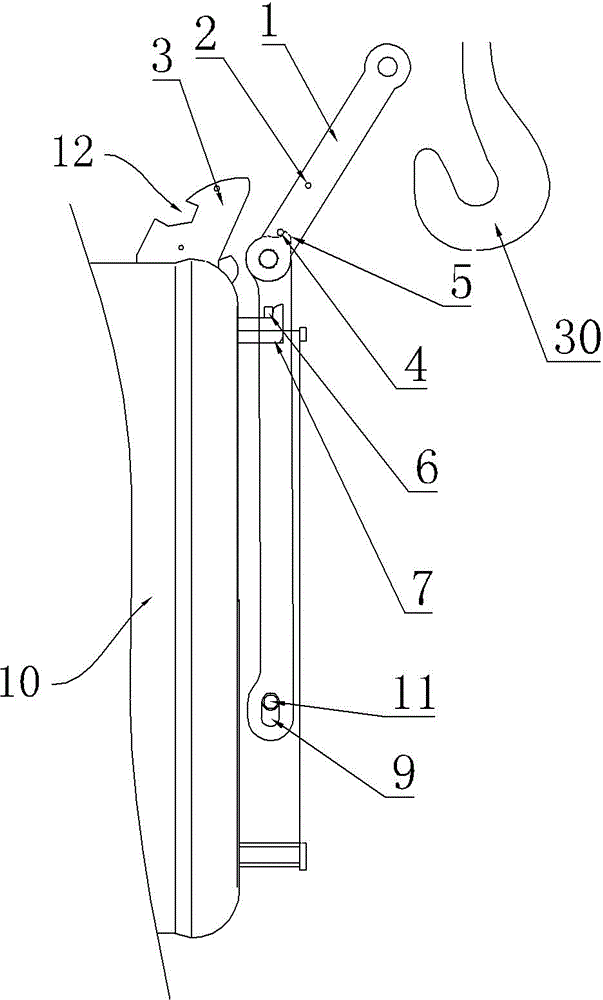

[0017] See figure 2 , image 3 and Figure 4 The ladle tipping mechanism of the present invention comprises a pull rod 1 and a connecting rod 8. One end of the connecting rod 8 is rotatably mounted on the bottom side of the ladle 10, and the other end is rotatably connected to the pull rod 1. The pull rod 1 is provided with a first hanging shaft 2, and the ladle The side of the bottom of 10 is fixedly equipped with pull rod support 3, pull rod support 3 has limit gap 12, when the ladle is vertically laid flat, the first hanging shaft 2 is limited by the limit gap 12, and connecting rod 8 is positioned at the bottom side of steel ladle 10. The rotatable connection end is provided with a long waist hole 9 extending along the length direction of the connecting rod, and the bottom side of the steel ladle 10 is fixed with a pin shaft 11, and the connecting rod 8 is rotatably connected and installed on the steel ladle 10 through the pin shaft 11 and the long waist hole 9 The side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com