Multi-spool take-up system for flatting mill

A technology of I-shaped wheel and flattening, which is applied in the field of multi-I-shaped wheel take-up system for flattening machines, can solve the problems of shortening the interval between taking-up and changing I-shaped wheels, difficulty in controlling and stabilizing product quality, and increasing labor intensity. Achieve the effect of maximizing the utilization rate of equipment, simple structure and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

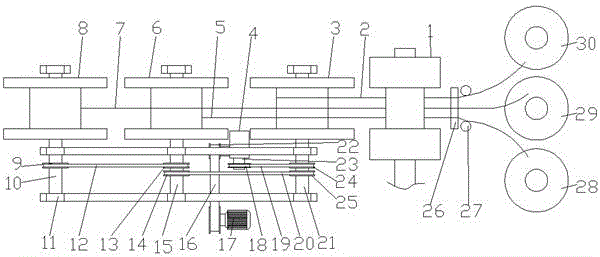

[0016] like figure 1 As shown, a multi-spool take-up system for a flattening machine includes a flattening machine 1, a guide device, a first pay-off reel 30, a second pay-off reel 29, a third pay-off reel 28, a first work Character wheel 3, the second I-shaped wheel 8, the third I-shaped wheel 6, frame 11, motor 17 and reduction box 4, said wire device includes two vertically arranged first cylindrical rollers 27 and is located on said second The second cylindrical roller 26 on the left side of a cylindrical roller 27 and horizontally arranged and parallel to the line of the two first cylindrical rollers 27, the first pay-off reel 30, the second pay-off reel 29 and the third pay-off reel The first copper wire 2, the second copper wire 7 and the third copper wire 5 are released correspondingly on the disc 28 respectively, and all pass through the wire device and then enter the flattening machine 1 to be rolled into flat copper wires; A first I-shaped wheel 3, a second I-shap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com