High-stability maca extract and preparation method, preparation and application thereof

A maca extract with high stability technology, applied in the field of food deep processing, can solve the problems of loose and porous substances, difficult to dissolve, rapid separation, etc., to ensure the taste and nutritional content, uniform extraction temperature, and prevent local coking Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

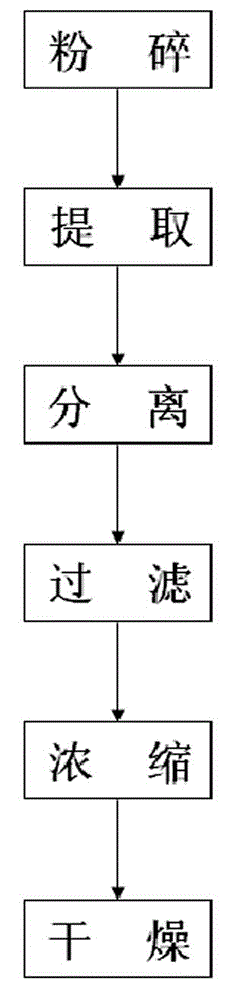

[0019] The preparation method of the high-stability maca extract of the present invention comprises the steps of pulverizing, extracting, separating, filtering, concentrating and drying, specifically comprising:

[0020] A, pulverization: take raw maca, pulverize through 60~250 mesh sieves;

[0021] B. Extraction: Put the crushed maca into the extraction tank, add water with a solid-to-liquid volume ratio of 3~8 times of maca, extract at 60~100°C for 1~8h, and extract 2~5 times in a cycle to obtain the extraction mixture ;

[0022] C. Separation: Centrifuge the extraction mixture at a centrifugal speed of 2500~3500r / min;

[0023] D. Filtration: Filtrate the centrifugate to obtain the filtrate;

[0024] E. Concentration: Concentrate the filtrate to a relative density of 1.08-1.25 to obtain an extract;

[0025] F, drying: dry the extract to a water content of 1-5% to obtain the target Maca extract.

[0026] The extraction tank described in step B is one of straight cone extr...

Embodiment 1

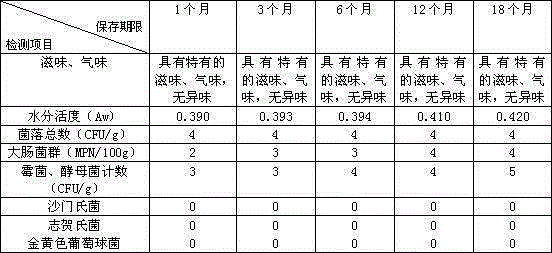

[0042] Take 3 kg of maca, crush it into 60~250 powder, add 12 liters of water, stir and heat to 70°C for extraction for 1 hour, pump it into a countercurrent horizontal screw discharge sedimentation centrifuge at a speed of 2900 r / min for centrifugation through the slag liquid pump, Carry out solid-liquid separation, return the solid part to the extraction tank, add 12 liters of water again, stir and heat to 70°C for extraction for 1 hour, and pump it into a countercurrent horizontal screw discharge sedimentation centrifuge at a speed of 2900 r / min for centrifugation through the slag-liquid pump , solid-liquid separation, plate and frame filtration, combined liquid, the membrane of the direct reverse osmosis method is concentrated into a thick paste with a specific gravity of 1.08 ~ 1.25, and then sent to the belt vacuum dryer, the belt speed is adjusted to 15cm / min, and the vacuum degree is controlled At 0.078-0.081MPa, the temperature of the material in the first, second, and...

Embodiment 2

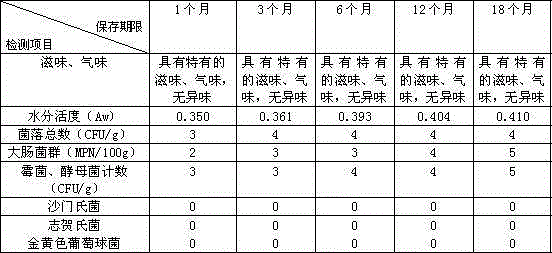

[0045]Take 3 kg of maca, crush it into 60~250 powder, add 15 liters of water, stir and heat to 80°C for extraction for 1.5 hours, pump it into a countercurrent horizontal screw discharge sedimentation centrifuge at a speed of 3000 r / min for centrifugation through the slag liquid pump, , carry out solid-liquid separation, return the solid part to the extraction tank, add 15 liters of water again, stir and heat to 80°C for extraction for 1.5 hours, and pour it into a countercurrent horizontal screw discharge sedimentation centrifuge at a speed of 3000 r / min through the slag-liquid pump for centrifugation Separation, carry out solid-liquid separation, return the solid part to the extraction tank, add 15 liters of water again, stir and heat to 80°C for extraction for 1 hour, and pump it into a countercurrent horizontal screw discharge sedimentation centrifuge at a speed of 3000 r / min through the slag liquid pump. Centrifugal separation, solid-liquid separation, titanium rod filtrat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com