Commercial fish grading and scaling equipment

A commercial fish and equipment technology, applied in fish sorting, fish cleaning/descaler, fish processing, etc., can solve the problems of pollution, unstable processing quality, high labor intensity, etc., and achieve low failure rate and good descaling effect , the effect of less manual intervention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

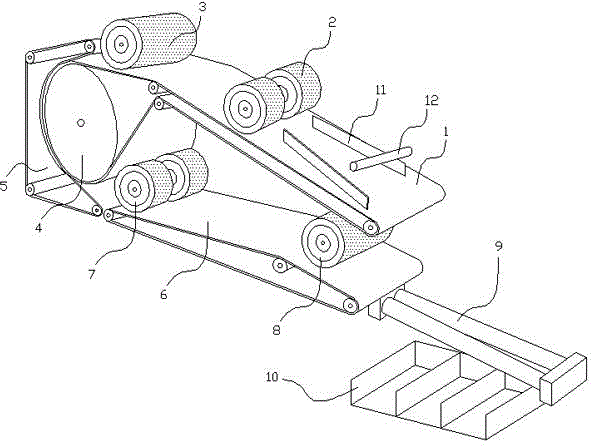

[0010] Example: refer to figure 1 , commercial fish grading and descaling equipment, including a feed belt 1, on which a front dumbbell brush 2 and a front strip brush 3 are arranged along the gap along the conveying direction, wherein: the front of the front dumbbell brush 2 is provided with a A guide plate 11 with a horn-shaped opening, with a spray pipe 12 near the guide plate 11; Holding belt 5; a discharge belt 6 is provided near the lower side of the clamping belt 5; a reverse dumbbell brush 7 and a reverse strip brush 8 are provided on the discharge belt 6 along the conveying direction gap; near the lower side of the discharge belt 6 end A drum filter 9 capable of sorting by size is provided. The commercial fish to be processed passes through the guide plate 11, the front dumbbell brush 2 and the front strip brush 3 successively under the drive of the feeding belt 1. The guide plate 11 adjusts the fish body to the axis consistent with the direction of action, and then ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com