Electrical switch forming a fast actuation circuit breaker

An electrical switch and conductive sheet technology, applied to the following types of electrical switches and electrical switches that function as circuit breakers, can solve problems such as difficulty in installing sliding components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

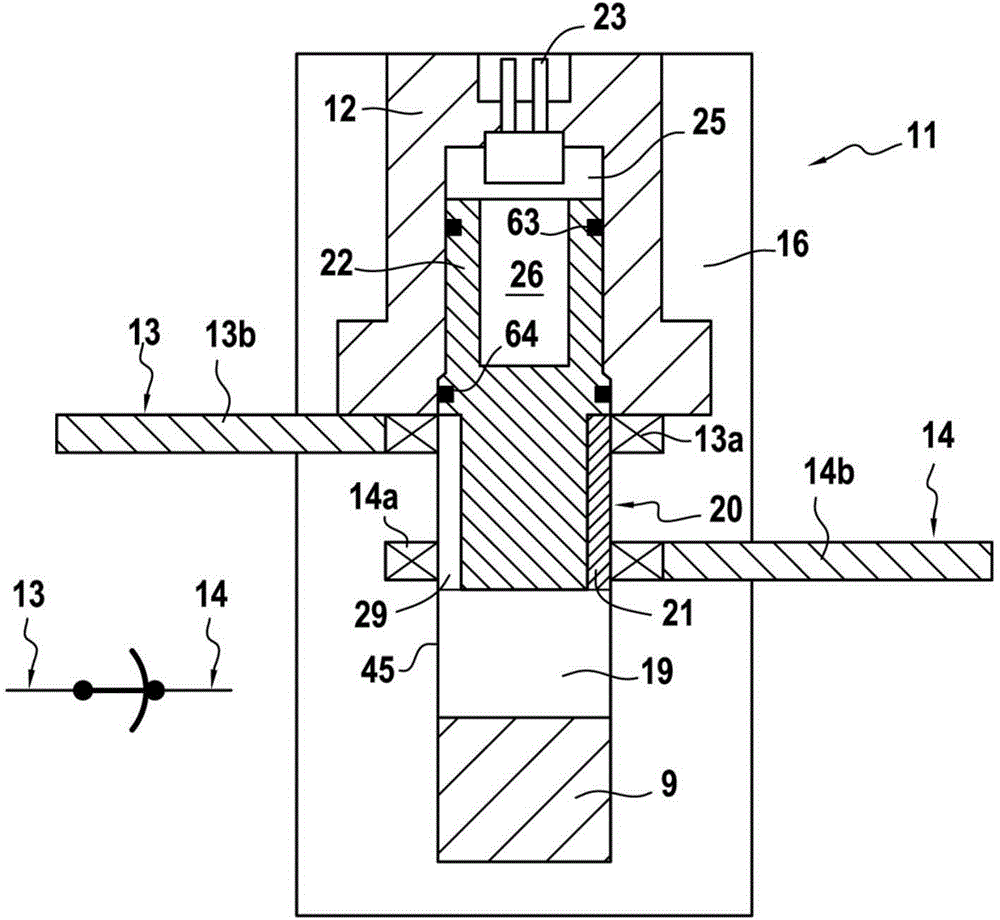

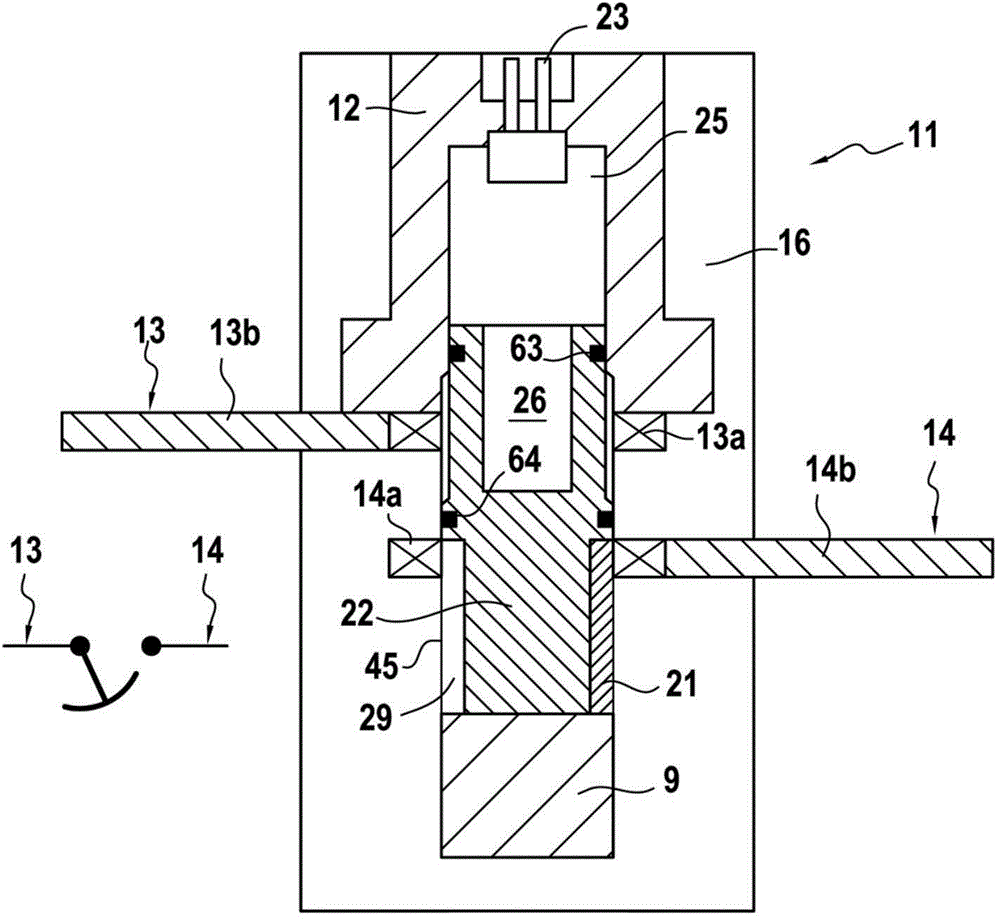

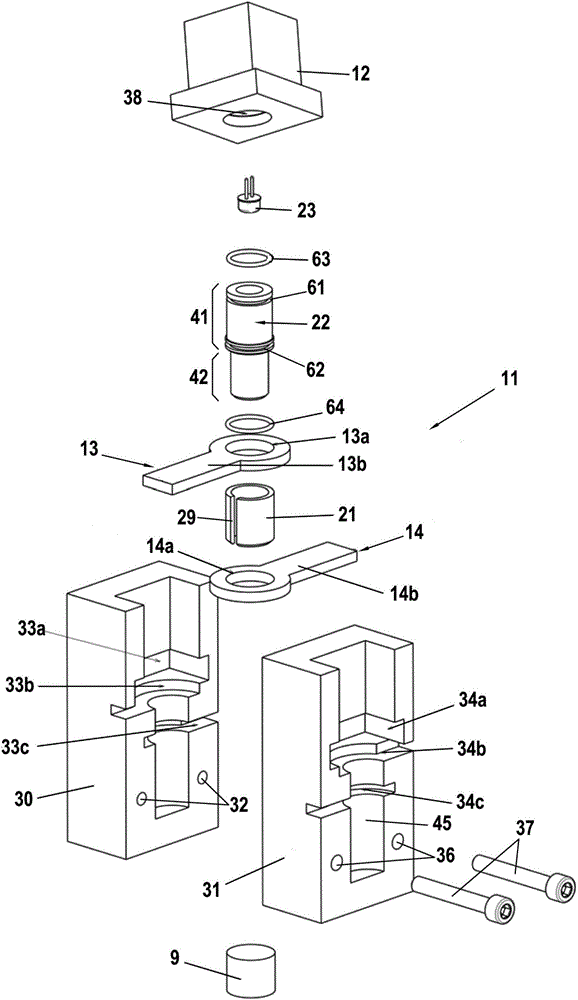

[0045] Referring more specifically to Figure 1 and figure 2 , it is possible to see a first embodiment of the electric switch 11 according to the invention, in this example the electric switch 11 more particularly constitutes a circuit breaker for any electric circuit connected to the two primary conductive strips 13 and 14 as defined above .

[0046] The circuit breaker switch 11 has a hollow body 16 of electrically insulating material defining a cavity 19 , an actuator 23 and two primary conductive strips 13 , 14 protruding into the cavity 19 .

[0047] The electric switch 11 also has a sliding assembly 20 adapted to move in the cavity. In the example shown, cavity 19 is cylindrical and slide assembly 20 itself is substantially cylindrical.

[0048] The slide assembly 20 includes a split tube 21 having at least one conductive portion. In Figure 1 and figure 2 In the example shown, the open tube 21 is electrically conductive as a whole.

[0049] The sliding assembly 20...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com