Novel carbon nanotube based organic composite thermoelectric material

A technology of carbon nanotubes and thermoelectric materials, which can be applied in the direction of lead-out wire materials of thermoelectric devices, etc., can solve the problems of complex preparation process and high price of conductive polymers, and can enhance electron transmission efficiency, reduce thermal conductivity, and improve scattering cross-section. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

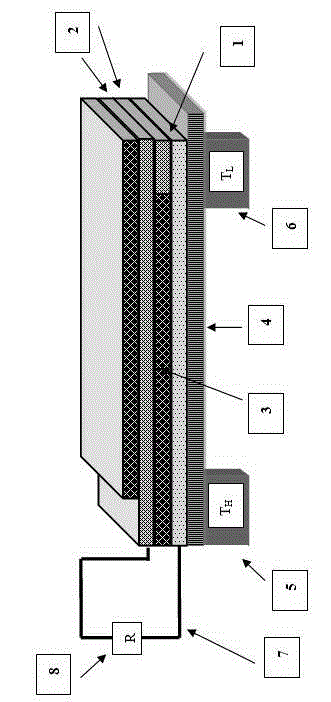

[0029] Such as figure 1 Shown: It includes a flexible organic polymer substrate layer 4, on which an n-type conductive layer 2 mixed with MWNTs and PVDF is sprayed; Insulation and isolation layer 3; on the insulation and isolation layer 3, a p-type conductive layer 1 mixed with PTh and PVDF is sprayed; Prepared by a mixed method to ensure uniform dispersion and mixing between MWNTs and PVDF, and between PTh and PVDF; the p-type conductive layer 1 and n-type conductive layer 2 are only connected to each other at one end.

[0030] The insulating isolation layer 3 is made of an insulating substance that does not react with the p-type conductive layer 1 and the n-type conductive layer 2 .

[0031] MWNTs, PTh and PVDF are all industrial grade supplies; the mass percentages of PTh and PVDF in the p-type conductive layer 1 are:

[0032] Name Mass %

[0033] PTh 70-90%

[0034] PVDF margin;

[0035] The mass percentages of MWNTs and PVDF in the n-type conductive layer 2 are:

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com