Design device of interstage air-entrapping structure of centrifugal compressor

A technology of centrifugal compressors and air-filling structures, applied in mechanical equipment, parts of pumping devices for elastic fluids, calculations, etc., can solve problems such as pulsation, affecting stage efficiency, and unit failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

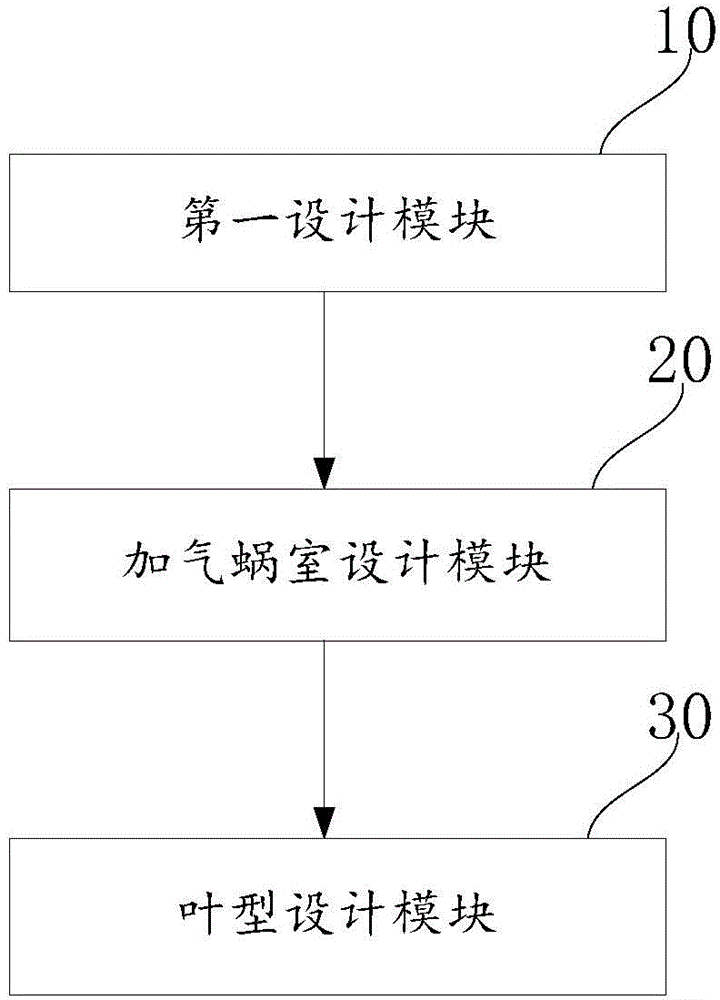

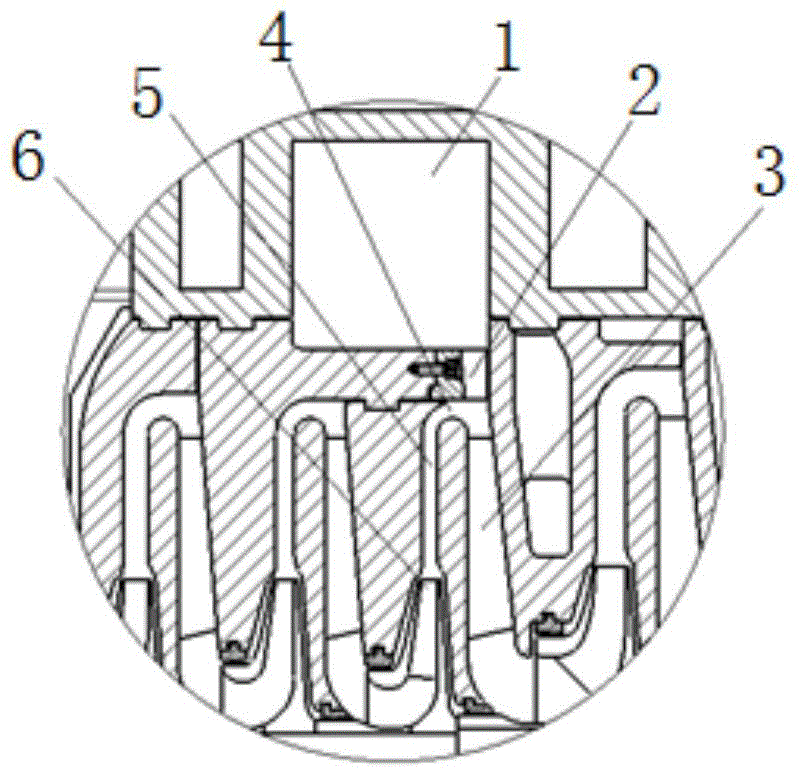

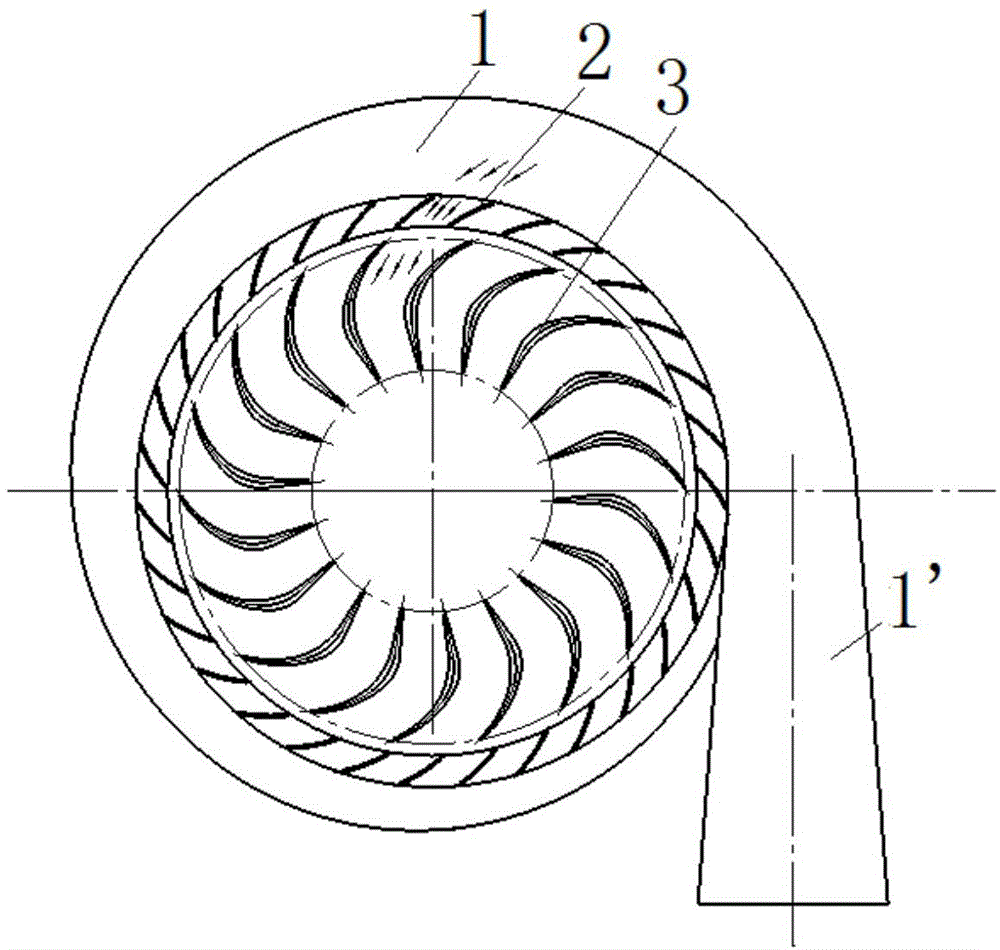

[0031] see figure 1 As shown, the design device for the interstage gas filling structure of the centrifugal compressor provided by the embodiment of the present invention includes a first design module 10 , an air filling volute design module 20 and an airfoil design module 30 . Wherein, the first design module 10 sets up an air filling port at the bend of at least one stage of the centrifugal compressor, and adds an air filling structure at the air filling port, so as to introduce the air filling airflow. see Figure 2-4 Specifically, an air filling port is provided at the bend 4 of the at least one-stage centrifugal compressor, and an air filling structure is added at the air filling port, so that the main air flow 9 is introduced into the air filling airflow 7 . The aeration structure includes an aeration volute 1 and an aeration volute 2 . Wherein, the volute of the air-filled volute is a variable-section volute. The aeration guide vanes 2 are evenly distributed in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com