Penetration and corrosion triaxial testing apparatus for gravel soil and testing method thereof

A triaxial test and test method technology, applied in the field of geotechnical engineering, can solve the problems of low collection efficiency of erosion particles, achieve the effect of improving the success rate of the test and avoiding the concentration of seepage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The following is a detailed description of the embodiments of the present invention: this embodiment is implemented on the premise of the technical solution of the present invention, and provides detailed implementation methods and specific operation processes. It should be noted that those skilled in the art can make several modifications and improvements without departing from the concept of the present invention, and these all belong to the protection scope of the present invention.

[0035] Specifically:

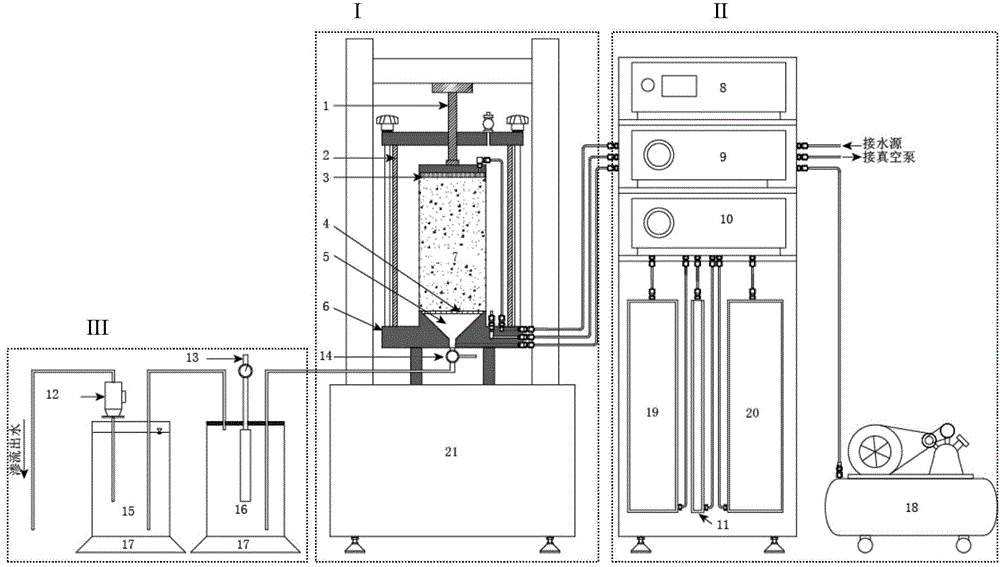

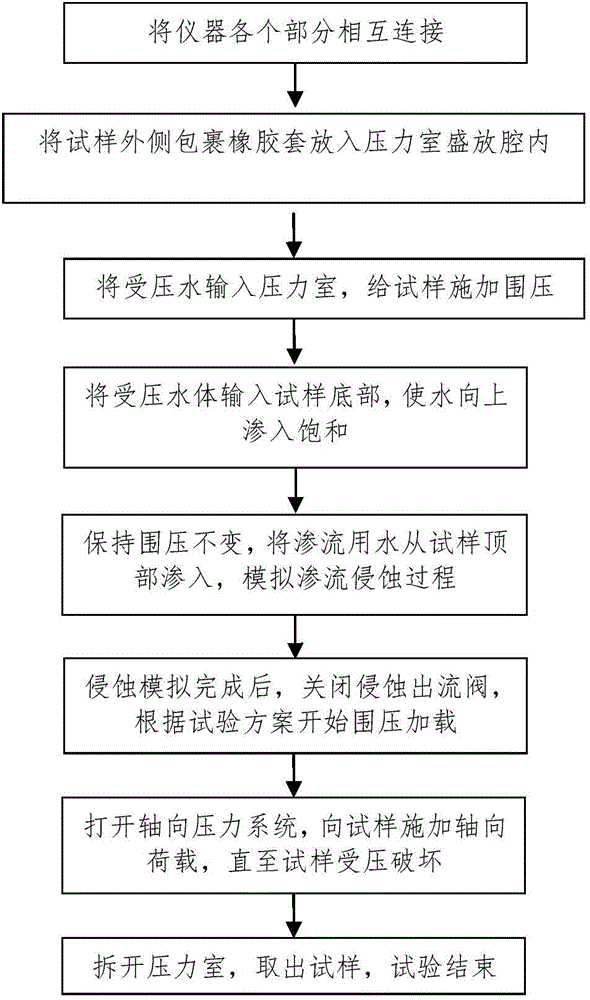

[0036] The gravel soil osmotic erosion triaxial test device provided in this embodiment includes a pressure control system, a osmotic erosion triaxial test system, and a sand-water separation system connected in sequence; Rocky soil samples, and through the self-loaded axial pressure and the confining pressure and water pressure provided by the pressure control system, an infiltration erosion environment with multi-level water heads and complex stress conditions i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com