System for safety detection of working reliability of mortar projectile series fuze

A detection system and reliability technology, applied in fuzes, weapon accessories, offensive equipment, etc., can solve the problems of high safety risk, high test cost, complex and dangerous operation process, accidental action of mobile fuze, etc., to reduce safety hazards, simple and fast Clamping is stable and the effect of reducing the cost of the test

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

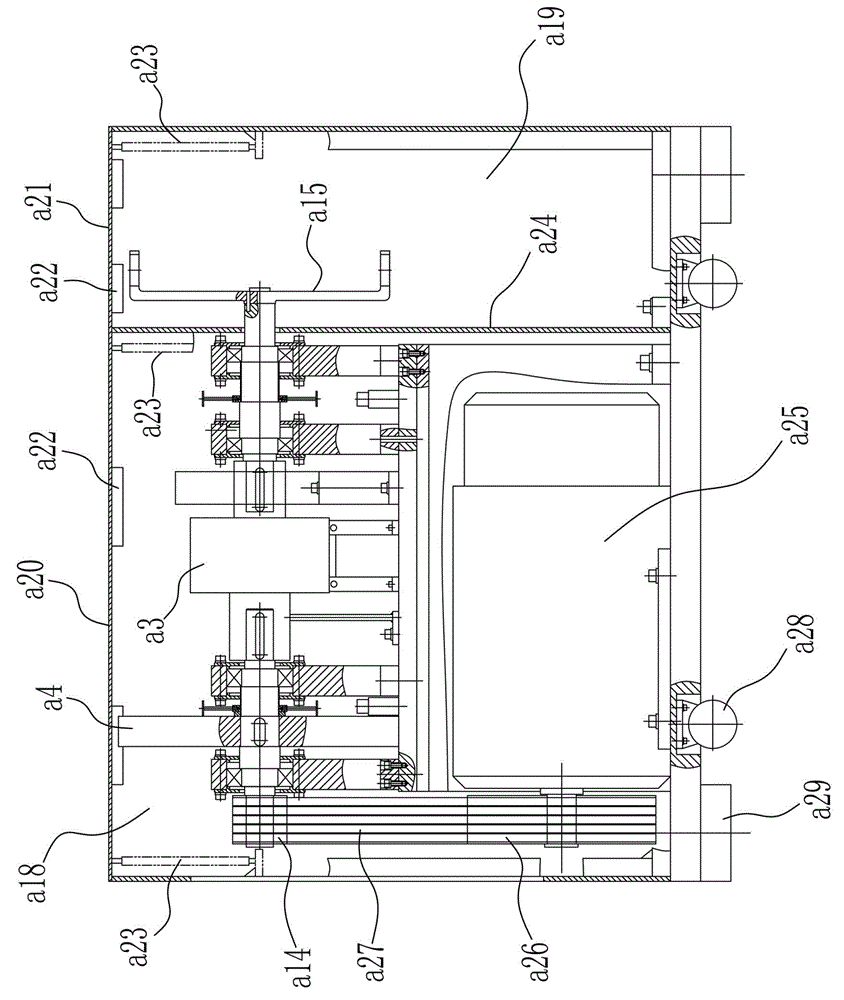

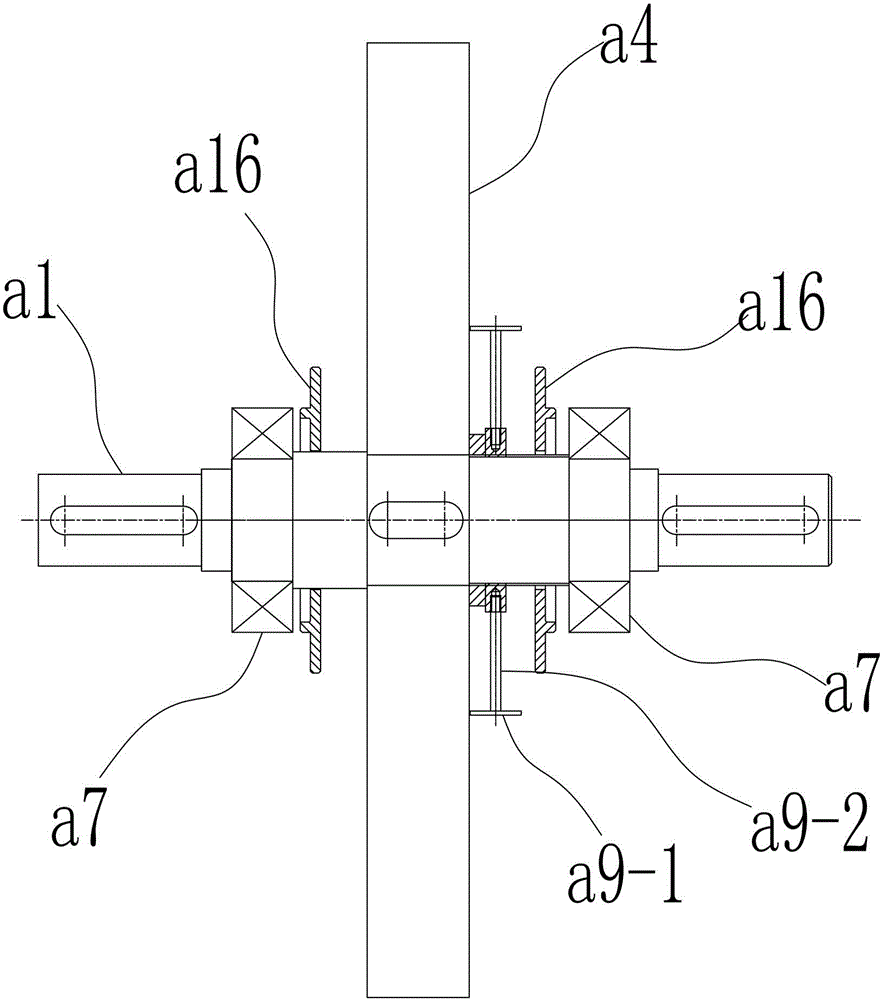

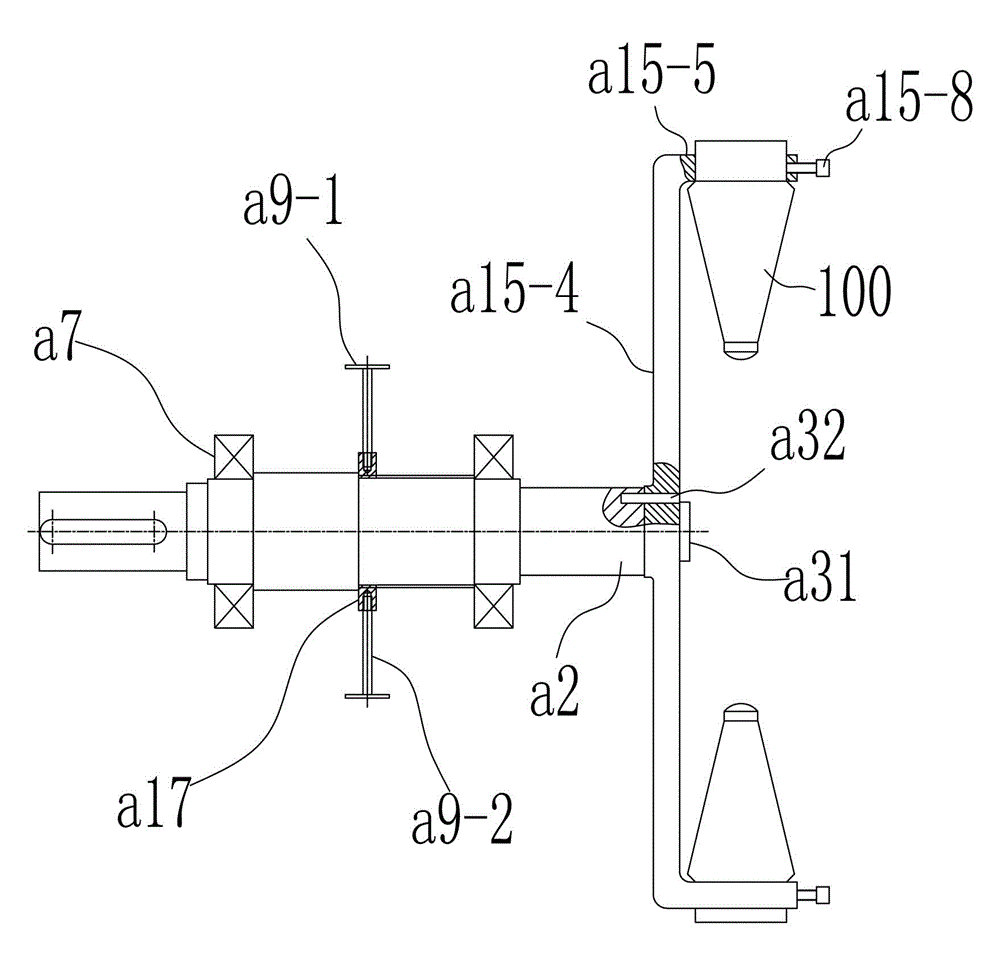

[0047] Attached below Figure 1-10 The present invention is further described in detail with specific embodiments.

[0048] A system for detecting the reliability and safety of the fuze action of the series of mortar bombs described in this embodiment, which includes the following Figure 1-7 The shown linear inertia safety simulation release subsystem for releasing the fuze rear seat safety mechanism (the first safety) and the attached Figure 8-10 Shown is the turbine safety mechanism (second safety) for disarming the fuze and blowing the blasting sub-system of the turbo safety fuze to detonate the fuze.

[0049] In this embodiment, an automatic control system is also included, and the effect of the automatic control system is to automatically control the centrifugal speed of the linear inertial insurance simulation release sub-system, the time before clutch, the clutch time and the blowing wind speed of the blowing detonation sub-system of the turbo insurance fuze, Blowin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com