Automatic bullet warhead collecting device

A technology of automatic collection and bullets, which is applied in the field of firearms, can solve the problems of personal injury, and achieve the effect of fast retrieval of bullets, simple operation and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

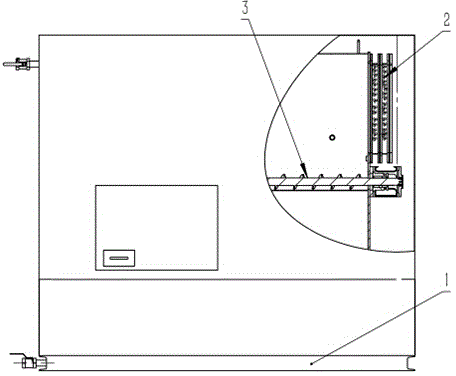

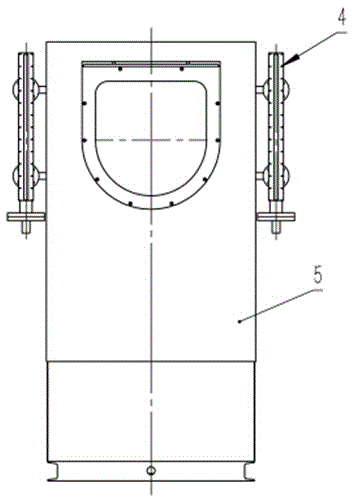

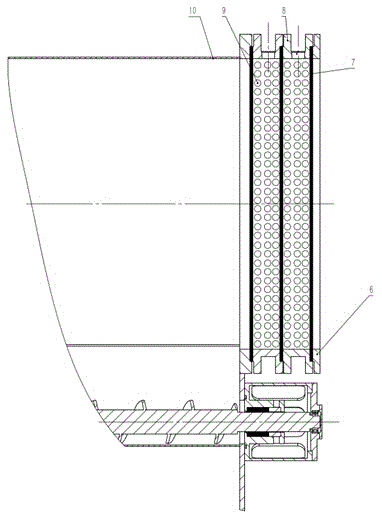

[0030] See attached figure 1 , 2 As shown, an automatic collection device for bullets and warheads, the automatic collection device for bullets and warheads mainly includes a frame 1, a bullet-stopping port assembly 2, an automatic bullet-retracting assembly 3, a bullet-stopping barrel 10, a liquid level display and control system 4 and Cover 5; wherein, the cover 5 is installed on the frame 1, the bullet-resistant tube 10, the bullet-resistant port assembly 2 and the automatic bomb-retracting assembly 3 are arranged in the cover 5, the liquid level display and control system 4 and the bullet-resistant tube 10 communicates with each other and is installed on the outside of the casing 5. The bullet-resistant cylinder 10 is a U-shaped structure with a buffer liquid medium inside. The bullet-resistant cylinder 10 is placed horizontally inside the casing 5. The bullet-resistant port assembly 2 and the automatic bullet-retracting assembly 3 Connected with the bullet-resisting cyli...

Embodiment 2

[0034] See attached figure 1 , 2 As shown, an automatic collection device for bullets and warheads, the automatic collection device for bullets and warheads mainly includes a frame 1, a bullet-stopping port assembly 2, an automatic bullet-retracting assembly 3, a bullet-stopping barrel 10, a liquid level display and control system 4 and Cover 5; wherein, the cover 5 is installed on the frame 1, the bullet-resistant tube 10, the bullet-resistant port assembly 2 and the automatic bomb-retracting assembly 3 are arranged in the cover 5, the liquid level display and control system 4 and the bullet-resistant tube 10 communicates with each other and is installed on the outside of the casing 5. The bullet-resistant cylinder 10 is a U-shaped structure with a buffer liquid medium inside. The bullet-resistant cylinder 10 is placed horizontally inside the casing 5. The bullet-resistant port assembly 2 and the automatic bullet-retracting assembly 3 Connected with the bullet-resistant cyli...

Embodiment 3

[0038] On the basis of Embodiment 1 or 2, as a further solution of the present invention: the elastic water blocking baffle is composed of more than two layers of methyl vinyl silicone rubber with a hardness of 40-70 Shore.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com