An electronically controlled full-time chain transfer assembly structure

A technology of assembly structure and transfer case, which is applied in the field of auto parts, can solve the problems of easy misoperation of manual shifting, difficulty in shifting, and large resistance in shifting operation, so as to achieve fast and accurate shifting operation and ensure work Stable, easy shifting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

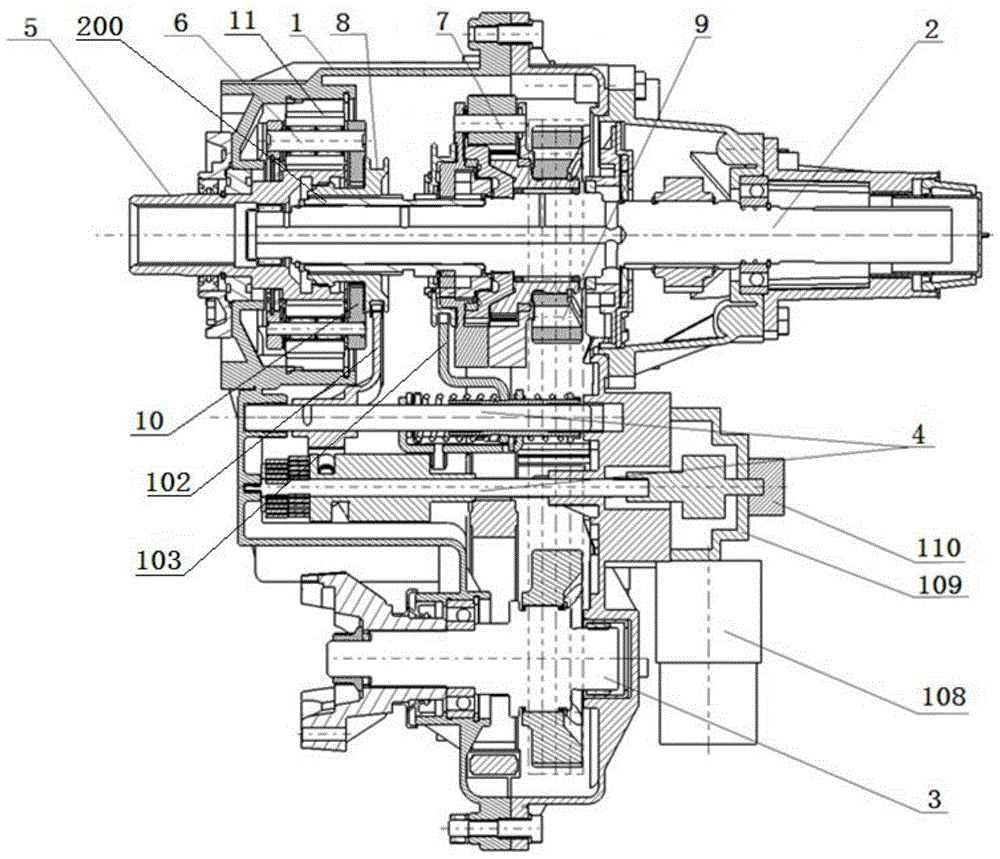

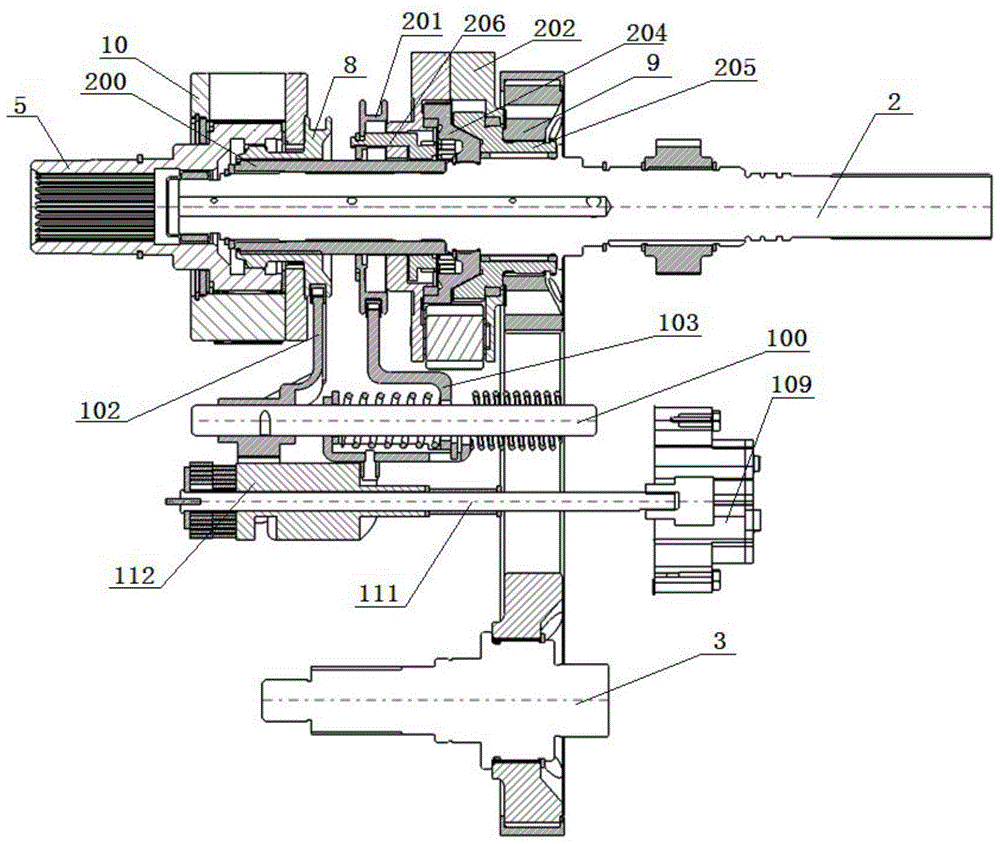

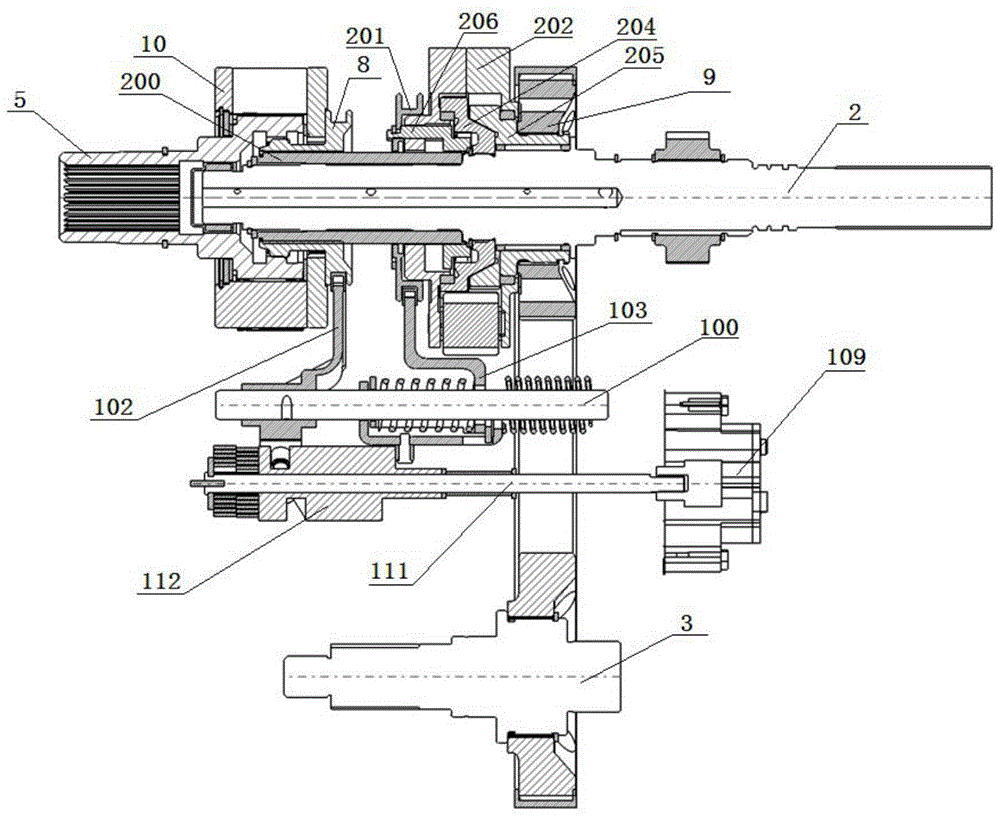

[0043] Such as figure 1 The electronically controlled full-time chain transfer assembly structure shown includes the transfer case 1, the rear axle drive shaft 2 and the front axle drive shaft 3 are arranged in the transfer case 1, and the front axle drive shaft 3 A shift control device 4 is provided between the rear axle drive shaft 2, the front end of the rear axle drive shaft 2 is provided with a transfer case input sleeve 5, and the rear axle drive shaft 2 is also provided with a drive shaft sleeve 200; The front part of the rear axle drive shaft 2 is set in the planetary reduction mechanism 6 , and the middle part is set in the planetary differential mechanism 7 . , the differential lock fork 103 of the gear shift control device 4 is positioned in cooperation with the differential lock fork sleeve 201 of the planetary differential mechanis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com