E-shaped magnetic core gum application tool

A magnetic core and adhesive technology, which is applied in the direction of mechanical equipment, connecting components, etc., can solve the problems of low efficiency of the adhesive method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The technical solutions of the present invention will be described in further detail below through specific implementation methods.

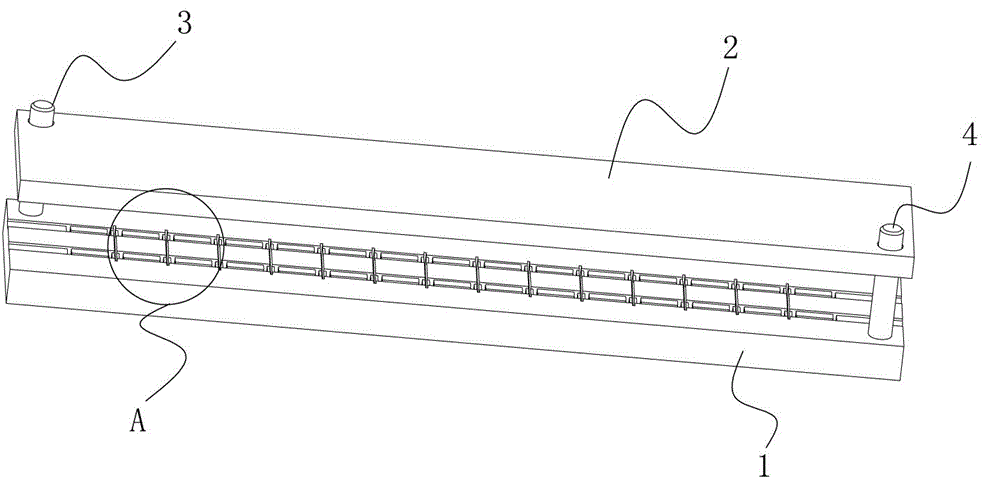

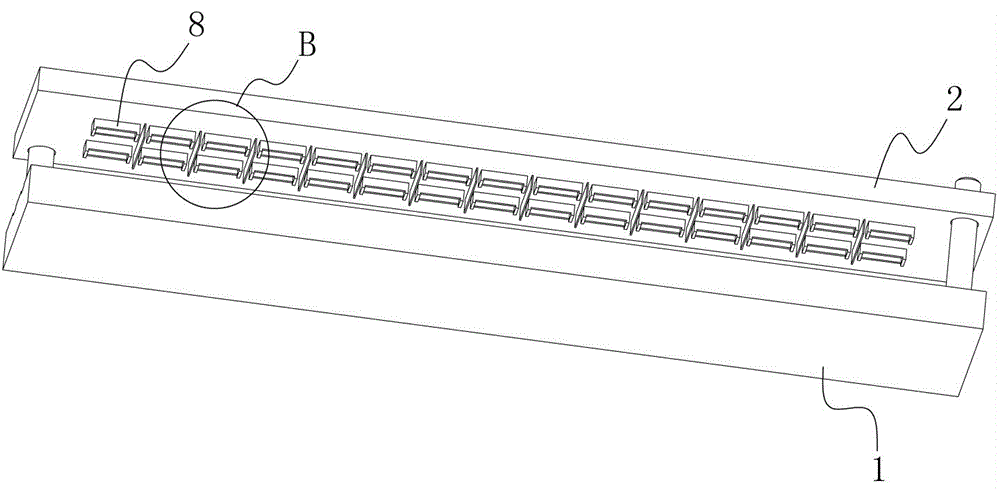

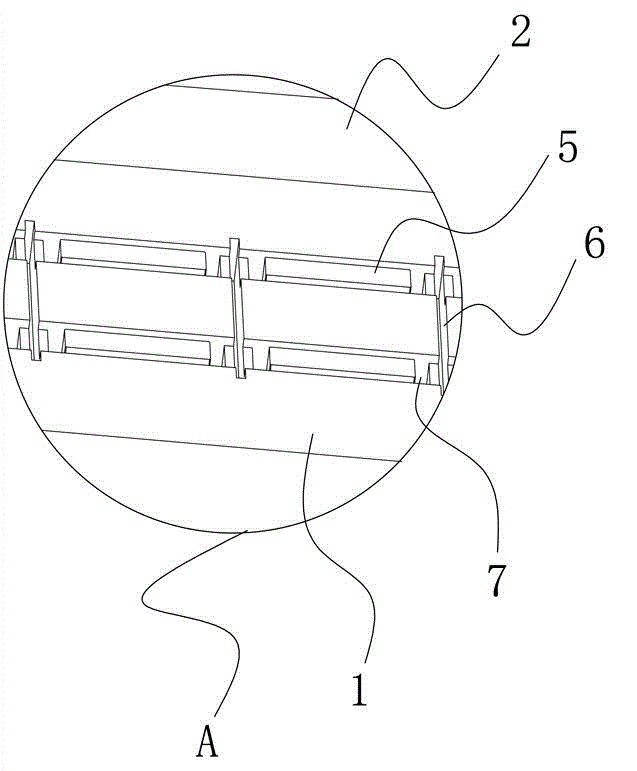

[0013] Examples of adhesive tooling for E-shaped magnetic cores, such as Figure 1-4 As shown, it includes a magnetic core installation mold 1 with a plurality of magnetic core accommodation grooves 7. In this embodiment, there are two rows of magnetic core accommodation grooves 7, and each row has fifteen magnetic core accommodation grooves 7. In other implementations In the example, it can be increased or decreased as required, there are two positioning columns (not shown in the figure) in the magnetic core accommodation groove 7, there is a cutting groove 6 between two adjacent magnetic core accommodation grooves 7, and the magnetic core installation mold 1 There are two guide columns 3, 4 on the guide column, and the mold upper cover 2 slides through the guide column. A plurality of extruded parts 8 are arranged on the lower surface o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com