Rigid connector of offshore buoyancy tank system

A technology of rigid connection and floating tank, which is applied in the direction of thin plate connection, connection components, mechanical equipment, etc., can solve the problems of affecting operation, inconvenient maintenance, high manufacturing cost, etc., and achieves improved reliability and convenience, simple and convenient maintenance, better effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

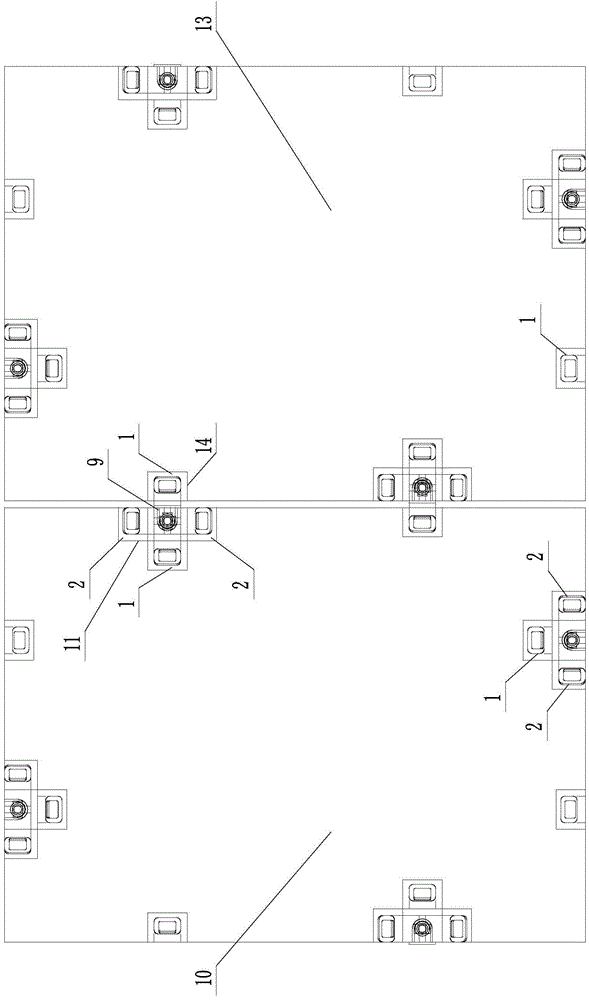

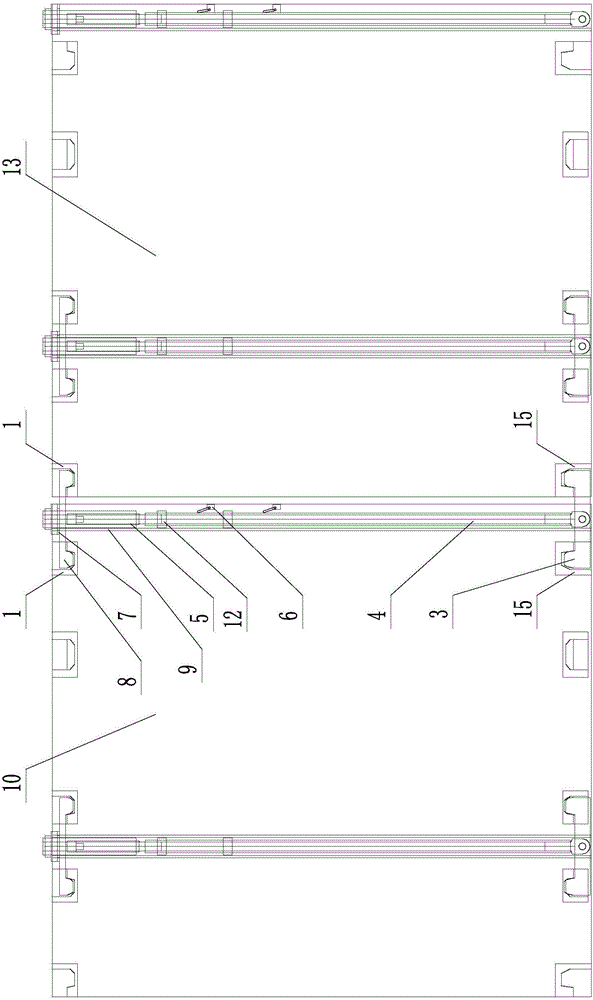

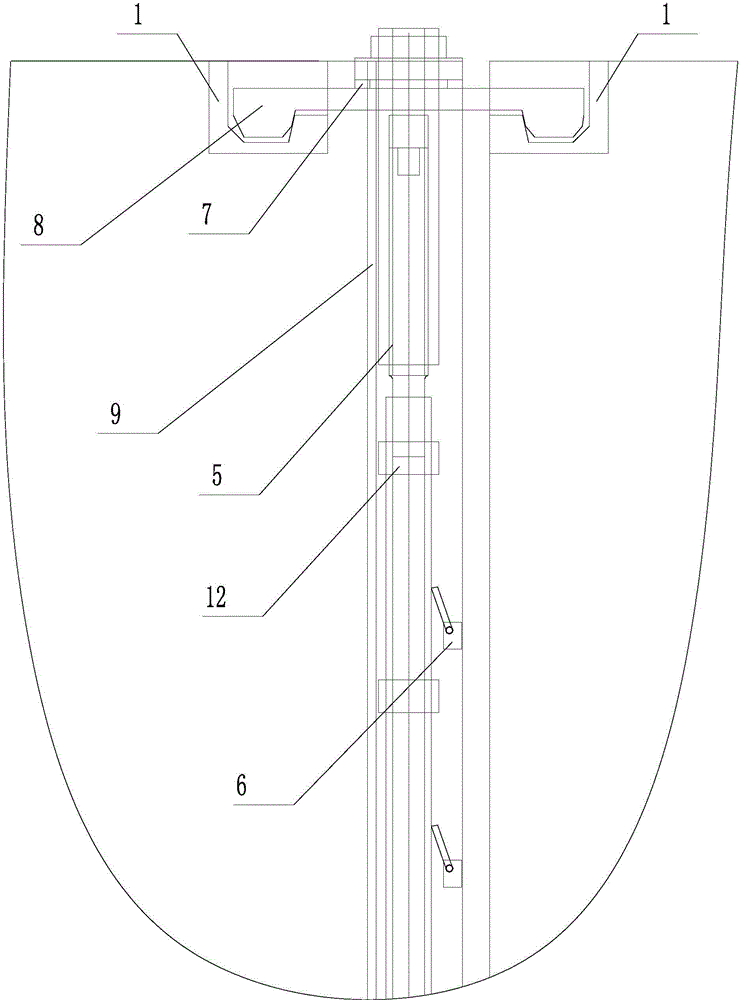

[0024] see Figure 1 ~ Figure 4 , a rigid connection joint of a marine buoyancy tank system, including a tie rod 4, which is installed in a vertical passage 9, and the vertical passage 9 is bent into a U shape by a steel plate and welded on the side of the buoyancy tank A10 Formed on the inside of the riser.

[0025] The lower end of the pull rod 4 is provided with a strip-shaped lower wedge hook 3 perpendicular to it, the middle part of the lower wedge hook 3 is hinged with the lower end of the pull rod 4, and a bar is respectively arranged on the two ends of the lower wedge hook 3. Wedge-shaped hook head; the limit sleeve 12 is fixedly connected on the pull rod 4; the upper end of the pull rod 4 is provided with a cylindrical nut 5 threade...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com