Self-adaptive intelligent hydraulic and pneumatic impact breaking hammer

An impact crushing and self-adaptive technology, which is applied to earth movers/excavators, construction, etc., can solve problems such as low work efficiency and energy waste, and achieve the effects of improving use efficiency, reducing work burden and labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

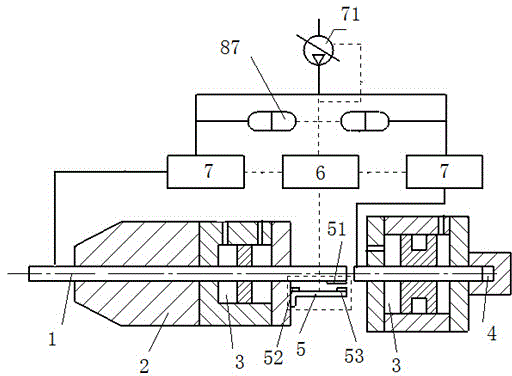

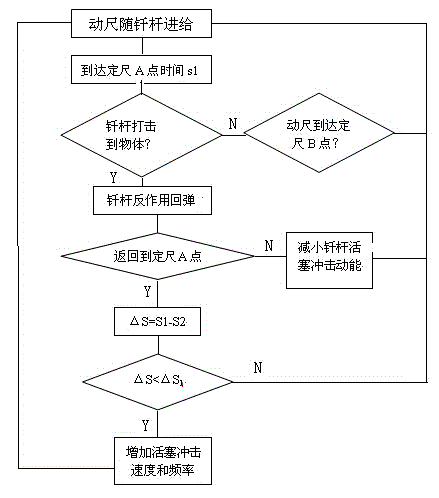

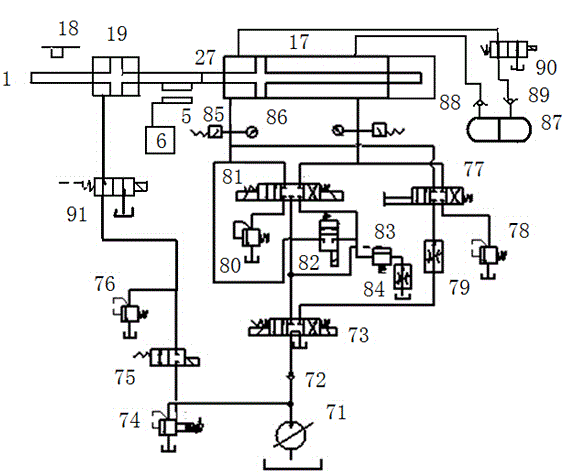

[0014] An adaptive intelligent hydraulic-pneumatic impact breaker, see figure 1 , including drill rod 1, drill rod reciprocating guide centering mechanism 2, piston reciprocating mechanism 3, airtight nitrogen volume change mechanism 4, grating position sensor 5, grating signal processing device 6 and servo drive system 7. The drill rod is positioned coaxially with the piston reciprocating mechanism through the drill rod reciprocating guiding centering mechanism, and the piston reciprocating mechanism is connected with the airtight nitrogen volume changing mechanism. The grating sensor is composed of a moving ruler 51 and two fixed rulers (A and B). The movable ruler is installed on the drill rod and reciprocates synchronously with the drill rod; the two fixed rulers are fixed on the drill rod reciprocating guide along the drill rod feeding direction. On the guide sleeve 21 of the centering mechanism, the fixed-length A ruler is on the top, and the fixed-length B ruler is on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com