A 3D mesh sewing machine

A sewing machine, 3D technology, applied to the sewing machine for sewing bedding, sewing machine components, sewing equipment, etc., can solve the problems of human injury, inconvenient operation, low production efficiency, etc., achieve the use of less parts, improve safety, The effect of improving productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

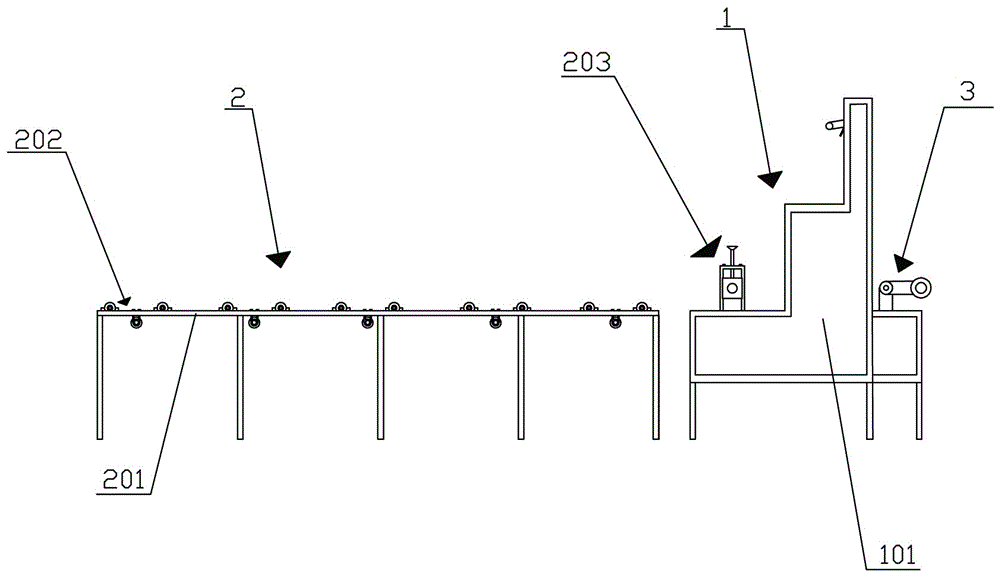

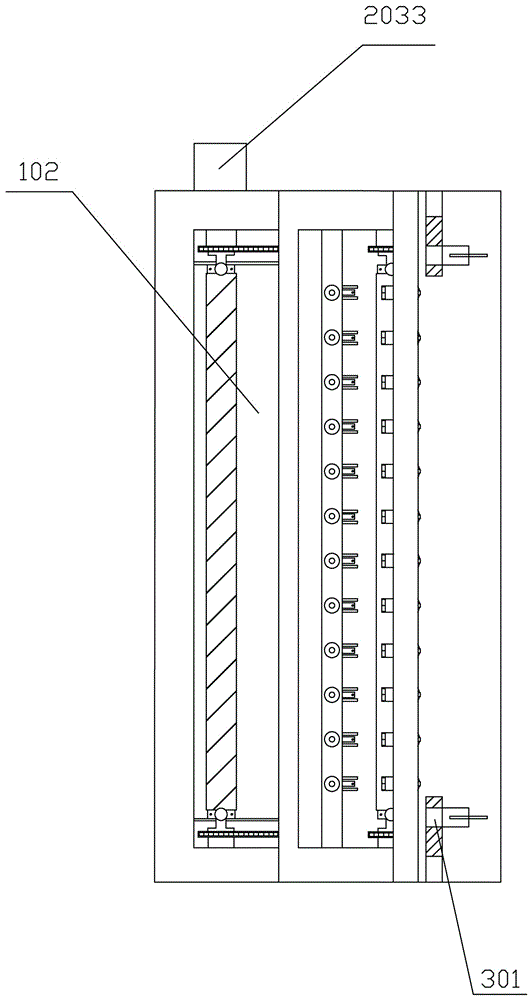

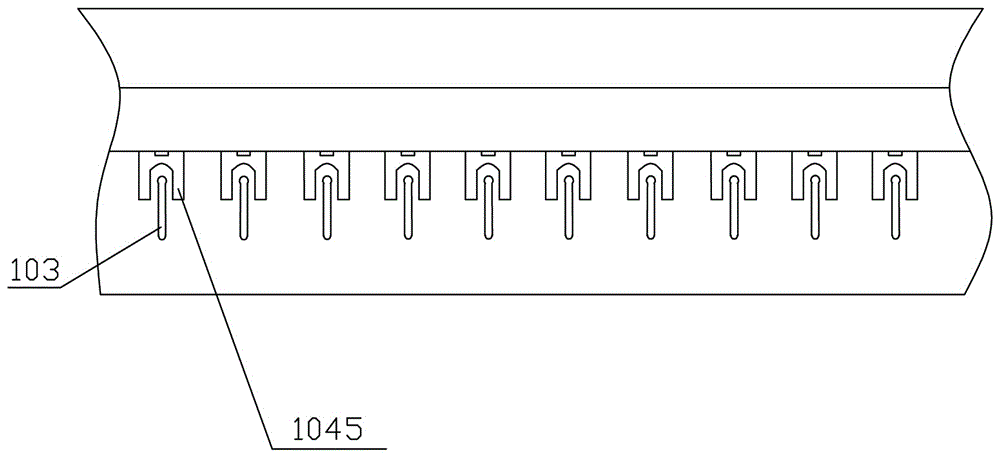

[0025] Refer to the attached figure 1 , attached figure 2 , attached image 3 and attached Figure 5 . A 3D mesh sewing machine, comprising a sewing device 1 and a feeding device 2 for conveying several 3D mesh fabrics to the sewing device 1, the sewing device 1 comprising a sewing frame 101 and a sewing machine There is a sewing table 102 on the manufacturing rack 101 and used for horizontal passage of several 3D meshes. The sewing table 102 is provided with a number of sewing openings 103. The sewing rack 101 is provided with a row along the sewing table. A number of sewing units 104 are arranged in the width direction and at equal intervals for synchronous single-line sewing of several 3D mesh cloths on the sewing table 102. A sewing needle 1041 that can move up and down, a rotatable hook 1042 located under the corresponding sewing opening 103, a bobbin 1043 for winding the spool, a stitching loop 1044 for matching with the spool, and for pressing and sewing There are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com