Production system of oil cake functional polypeptide

A production system, multi-functional technology, applied in the direction of enzyme production/bioreactor, specific-purpose bioreactor/fermenter, biochemical instrument, etc., can solve the problem of low work efficiency of production system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

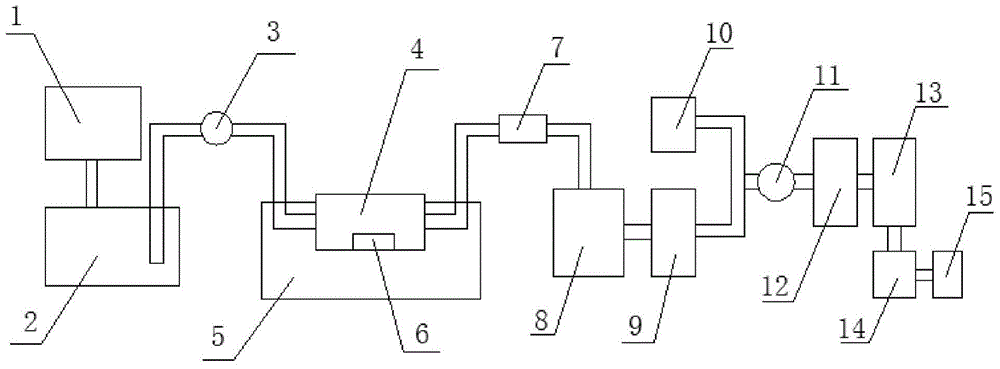

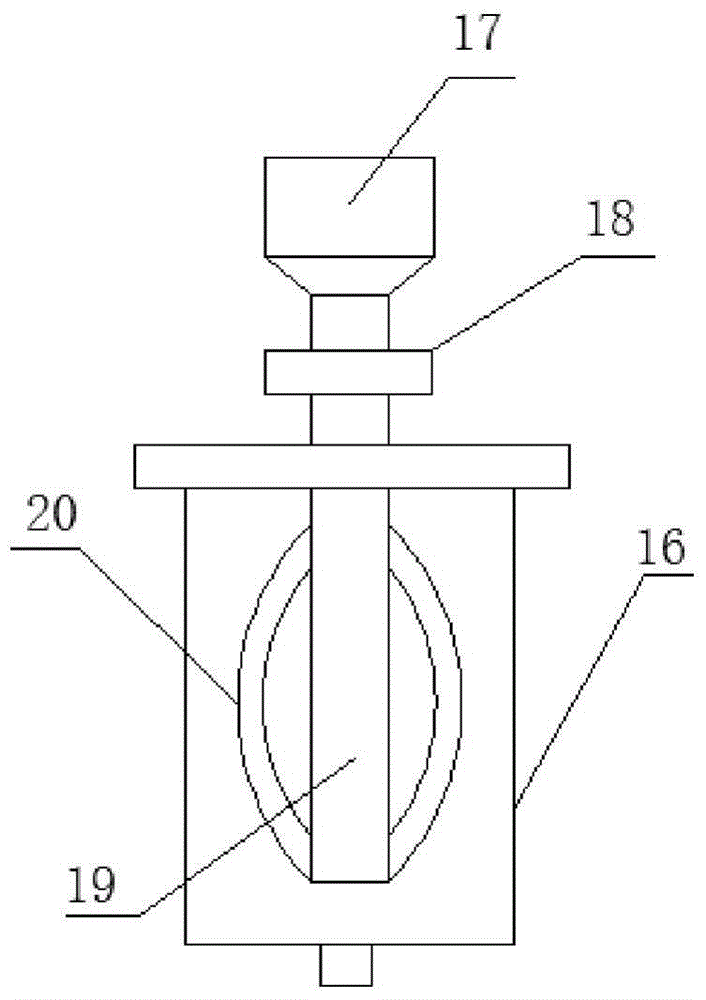

[0012] Such as figure 1 The production system of a kind of grease cake functional polypeptide shown, comprises pulverizer 1, dissolving bottle 2, extraction pool 4, collection bottle 8, ultrasonic-assisted enzymolysis device, separator 14 and ultrafilter 15, described pulverization The machine 1 is connected with the dissolution bottle 2, and the extraction pool 4 is connected with the dissolution bottle 2 and the collection bottle 8 through pipelines respectively, and a pump 3 is arranged on the pipeline between the extraction pool 4 and the dissolution bottle 2. The pipeline between the extraction pool 4 and the collection bottle 8 is provided with a suppressor 7, the extraction pool 4 is placed in the water tank 5, the extraction pool 4 is provided with an ultrasonic oscillator 6, and the collection bottle 8 It is connected with ultrasonic-assisted enzymolysis device, and described ultrasonic-assisted enzymolysis device is connected with separator 14 successively, and descr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com