Film tearing mechanism

A cylinder and jacking technology, which is applied in the field of tearing film mechanism equipment, can solve the problems of high labor intensity, slow peeling speed, damaged products, etc. of manual operation, and achieve the effects of convenient absorption and throwing, lower production costs, and lower defect rates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

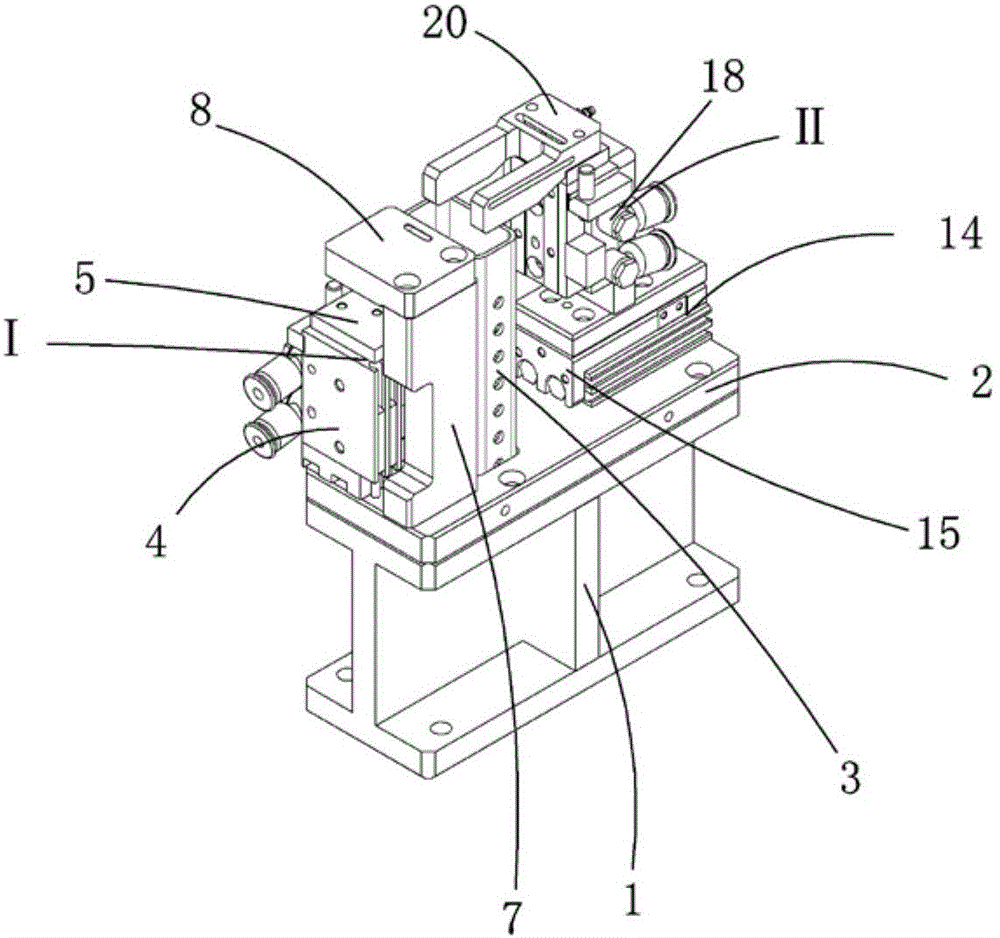

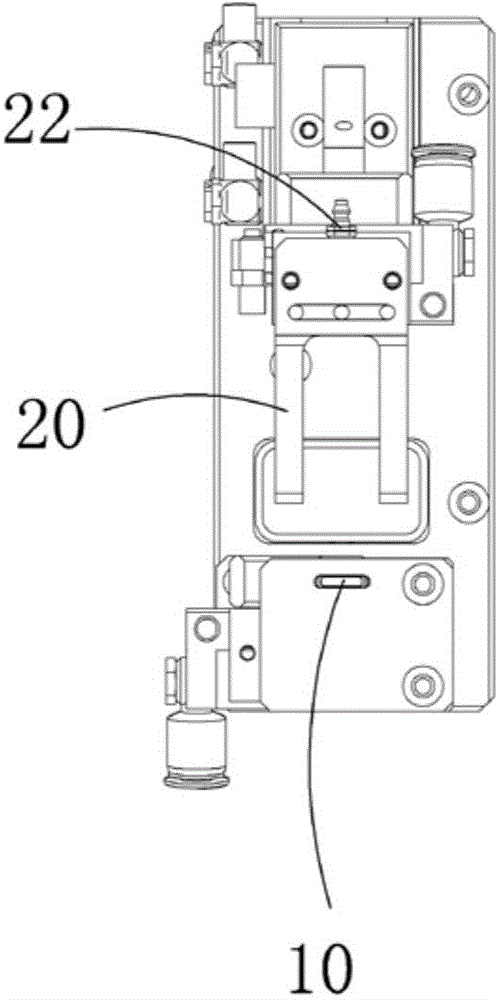

[0025] Examples, see attached Figure 1~6 , a film tearing mechanism, which includes a base 1, a cylinder mounting plate 2 is installed on the base, a product jacking device I is installed on the left upper part of the cylinder mounting plate, a waste box 3 is installed on the middle part, and a suction shifting device is installed on the upper right part Device Ⅱ, the product jacking device can place the product with release paper, and can lift the product from the release paper, which is convenient for the retrieving mechanism to take the product; the release paper is placed in the waste box, and the waste box is a square shell structure, and there is a ventilation hole on the side wall of the waste box; the suction and displacement device can press and suck the release paper and move the release paper into the waste box.

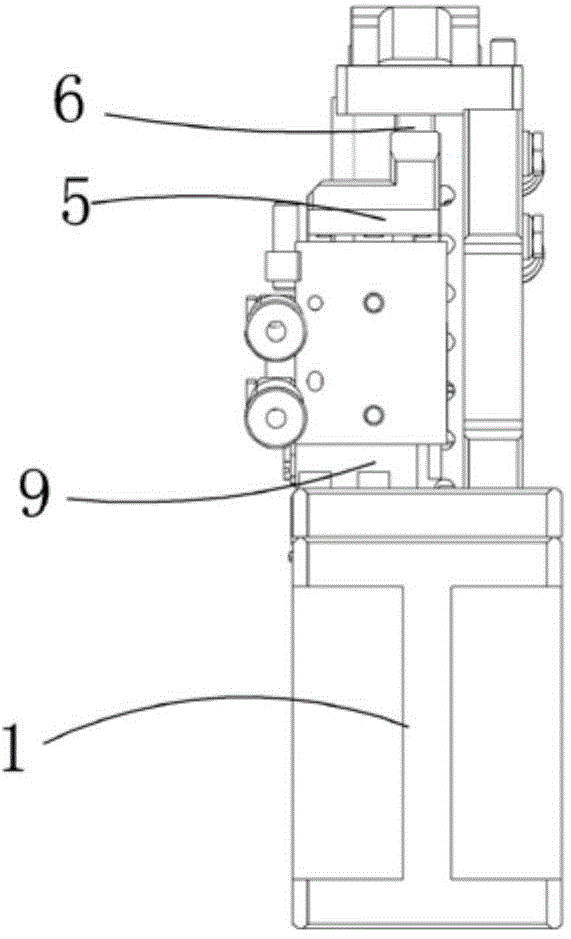

[0026] The product jacking device includes a jacking cylinder 4, a push block 5, a push rod 6, a vertical plate 7 and a supporting plate 8, and the jacki...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com