X-ray prevention shielding film and preparation method thereof

An X-ray and film technology, applied in the field of anti-X-ray shielding film and its preparation, can solve the problems of insufficient softness, poor conformability, radiation leakage, etc., achieve strong durability, increase service life, and improve wear resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

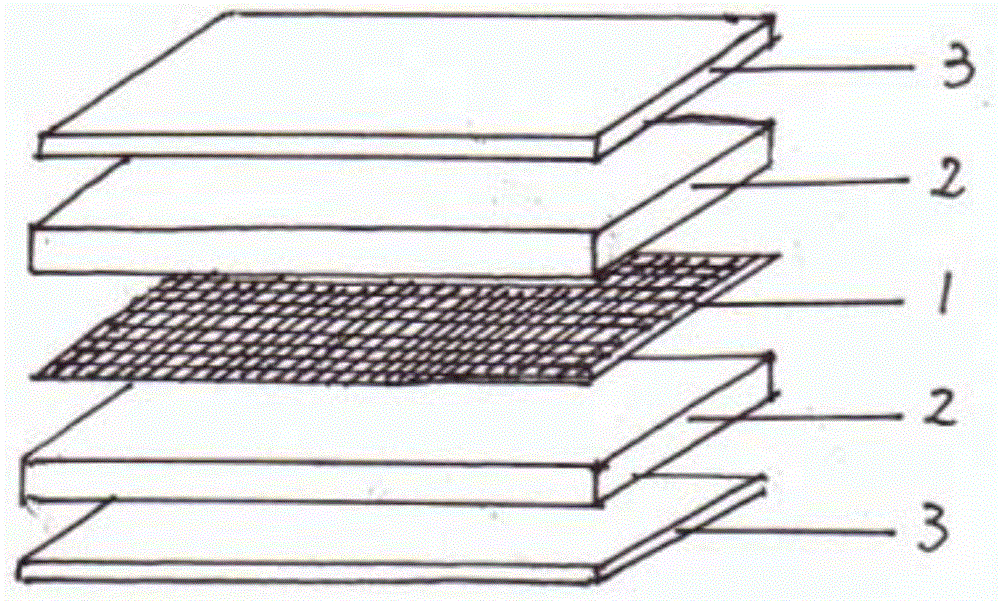

[0031] A method for preparing an X-ray shielding film, comprising the following steps:

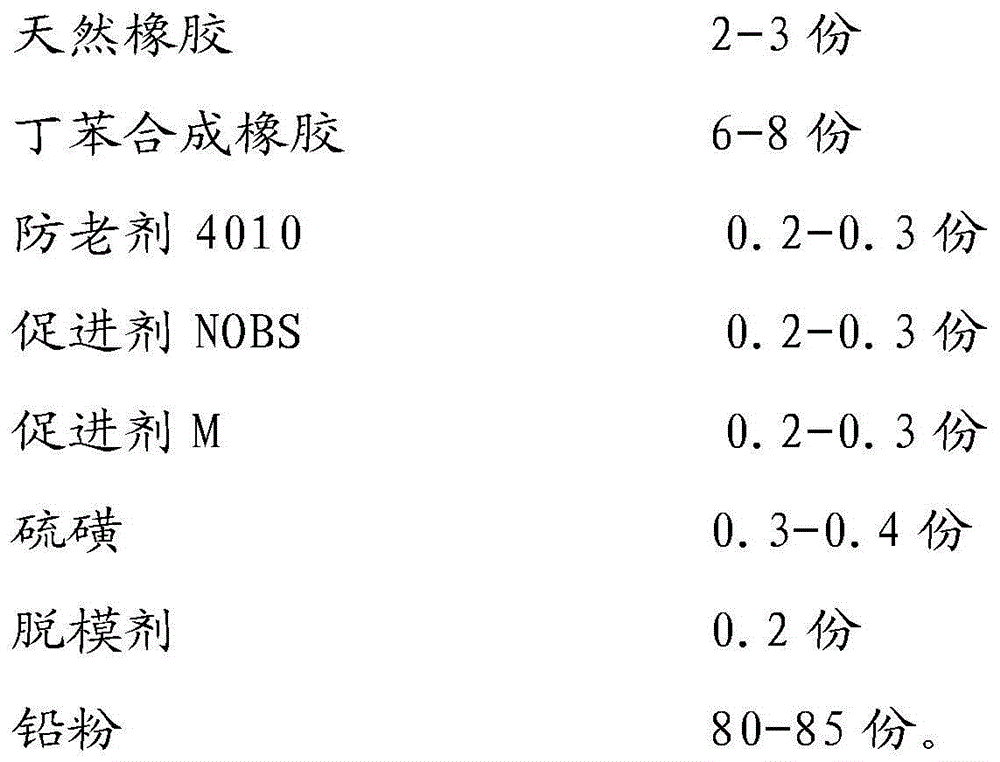

[0032] Step 1) mixing natural rubber layer, styrene-butadiene synthetic rubber, anti-aging agent, accelerator, sulfur, release agent and lead powder into lead rubber layer by two-roll rubber mixing machine;

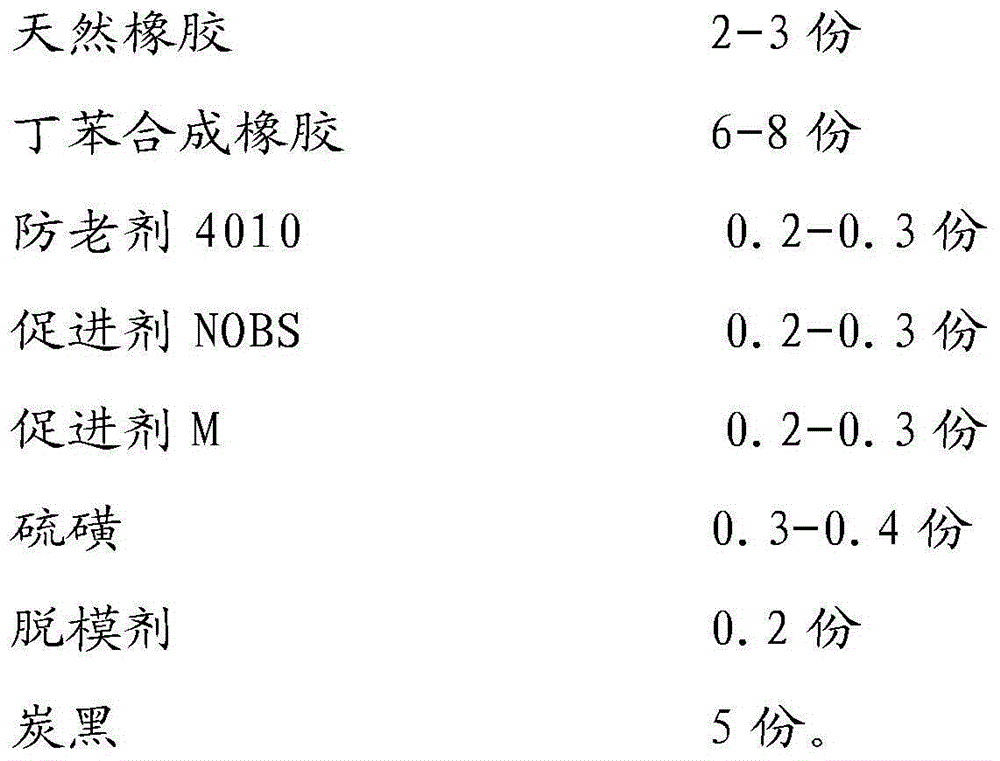

[0033] Step 2) mixing the natural rubber layer, styrene-butadiene synthetic rubber, anti-aging agent, accelerator, sulfur, release agent and carbon black into a wear-resistant rubber layer by a two-roller rubber mixer;

[0034] Step 3) stretching the product obtained in step 1 and step 2 through the pressure of a three-roll calender to form a sheet;

[0035] Step 4) Heat the lead rubber layer, reinforcing fabric layer, and protective layer through a flat carding machine, pressurize the carding machine, set the heating temperature to 140-145 ° C, and the heating time is 20 minutes;

[0036] Step 5) Punching the pieces;

[0037] Step 6) Verify the installation.

[0038] Accelerator N...

Embodiment 1

[0042] Select 2 parts of natural rubber, 7.5 parts of styrene-butadiene synthetic rubber, 0.25 parts of N-cyclohexyl-N'-phenyl-p-phenylenediamine, N-(diethylene oxide)-2-benzothiazole sulfenamide or 2 -0.25 part of (4-morpholinethio) benzothiazole, 0.25 part of 2-mercaptobenzothiazole, 0.35 part of sulfur, 0.2 part of release agent, 82 parts of lead powder to prepare lead rubber layer

[0043] Select 2-3 parts of natural rubber, 6-8 parts of styrene-butadiene synthetic rubber, 0.2-0.3 parts of N-cyclohexyl-N'-phenyl-p-phenylenediamine, N-(diethylene oxide)-2-benzo Thiazole sulfenamide or 2-(4-morpholinethio)benzothiazole 0.2-0.3 parts, 2-mercaptobenzothiazole 0.2-0.3 parts, sulfur 0.3-0.4 parts, mold release agent 0.2 parts, carbon black 5 parts to prepare a wear-resistant rubber layer.

[0044] The natural rubber layer, styrene-butadiene synthetic rubber, anti-aging agent, accelerator, sulfur, release agent and lead powder are mixed into a lead rubber layer through a two-rol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com