Horizontal positioning device for rotation electrode extruding machine

A technology of horizontal positioning and rotating electrodes, applied in the direction of presses, material forming presses, manufacturing tools, etc., can solve the problems of vibration, the impact of electrode quality, the inability to guarantee the electrode extrusion speed, etc., to achieve stable and reliable speed, improve The effect of product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with accompanying drawing and example.

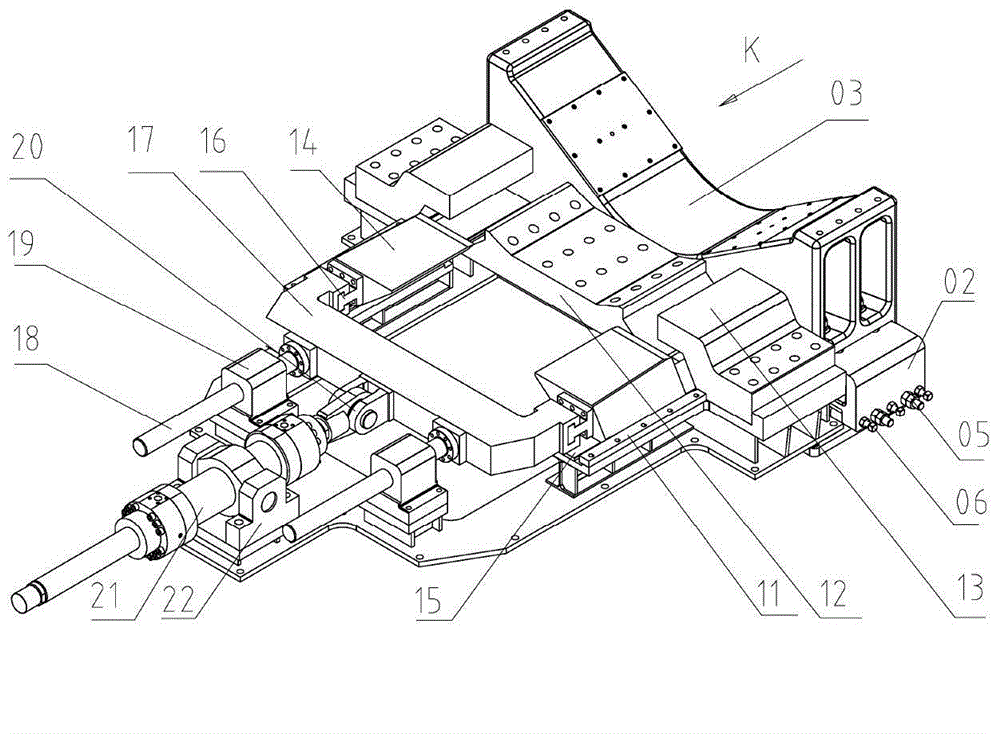

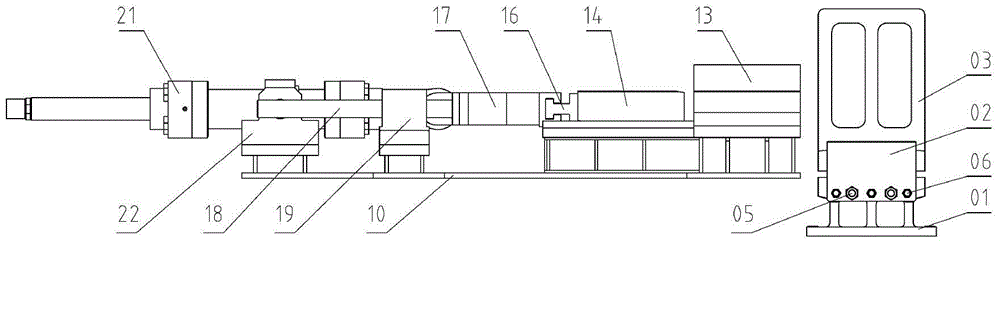

[0015] The horizontal positioning device of the rotary electrode extruder of the present invention is provided with a fixed support and a horizontal locking mechanism. The fixed support mechanism includes wedges 02 placed at both ends of the upper surface of the base 01, the V-shaped block 03 fastened with a backing plate 04 is placed between the wedges 03, and the lower part of the side of the wedge 02 is opposite to the side of the base 01 Bolt assembly 05 and top screw 06 are provided. When installing, first fix the base 01 on the foundation, then put the wedge 02 on the base, and finally put the V-shaped block 03 on the two wedges, and fasten the backing plate 04 on the inner surface of the V-shaped block. When the rotary extruder rotates from the vertical state to the horizontal state, the cylinder body 08 is in contact with the backing plate 04, and the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com