Multi-point positioning device

A multi-point positioning and mounting hole technology, used in workpiece clamping devices, manufacturing tools, etc., can solve the problem that multiple clamping points cannot be linked together, and achieve the effect of convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

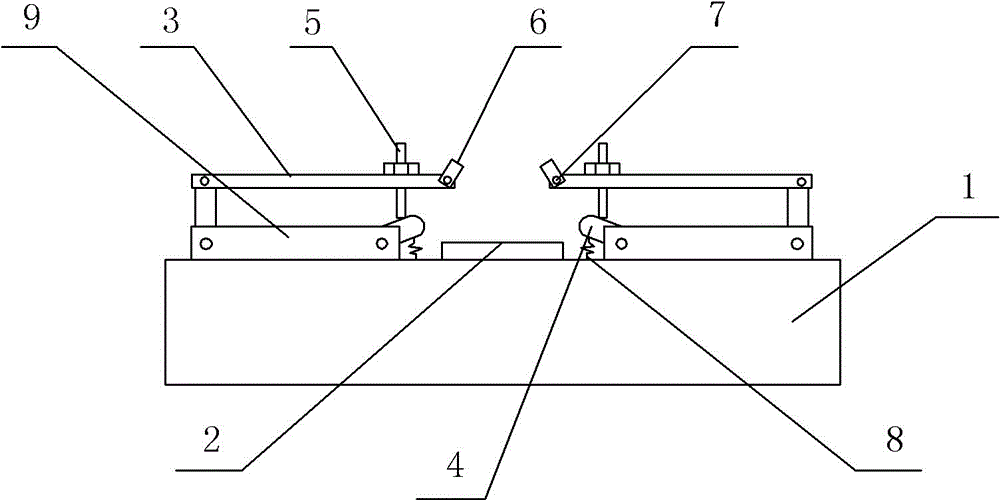

[0013] The reference numerals in the accompanying drawings of the description include: base 1 , workbench 2 , first jaw 3 , second jaw 4 , adjusting bolt 5 , collet 6 , hinge bolt 7 , compression spring 8 , frame 9 .

[0014] Such as figure 1 As shown, a multi-point positioning device in this embodiment includes a base 1, a workbench 2 for placing workpieces, jaws, a frame 9 installed on the base 1, and the workbench 2 is installed on the base 1. Frame 9 is positioned at both sides of workbench 2. The jaws include a first jaw 3 and a second jaw 4 hinged on the frame 9, the first jaw 3 is located above the second jaw 4, the height difference between the first jaw 3 and the second jaw 4 is 10 cm. The first jaw 3 is provided with a mounting hole, and an adjusting bolt 5 is arranged in the mounting hole, and the lower end of the adjusting bolt 5 can be offset against the second jaw 4 . One end of the first jaw 3 close to the workpiece is provided with a threaded hole, and the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com