Powder grinding equipment

A powder and equipment technology, applied in the field of powder grinding equipment, can solve the problems of high unit energy consumption, clogging of materials, easy inhalation of operators, etc., to achieve uniform grinding particle size, prevent unqualified powder from entering, powder The effect of narrow bulk particle size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

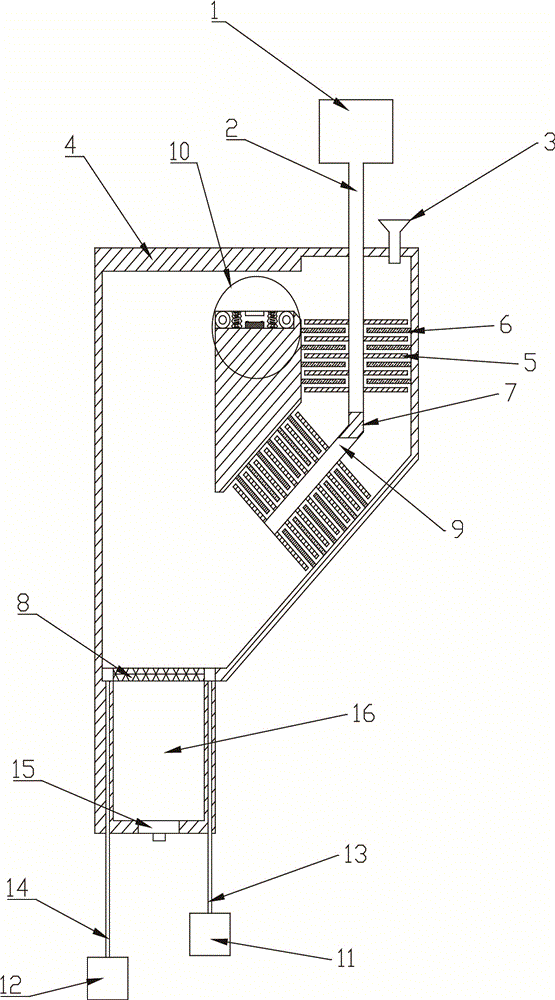

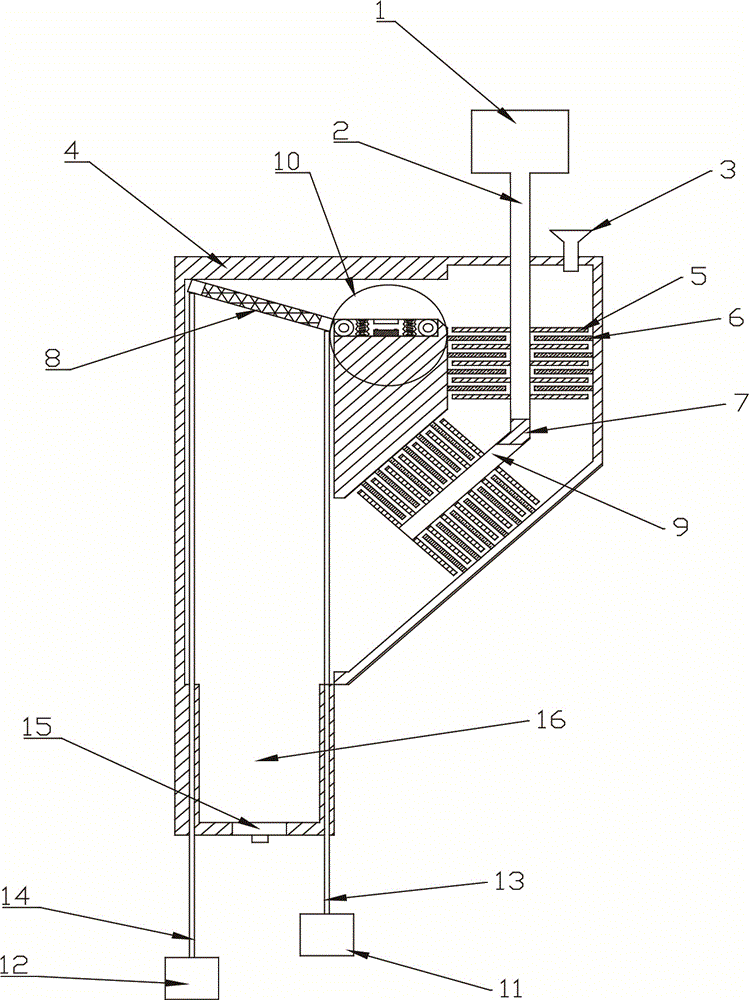

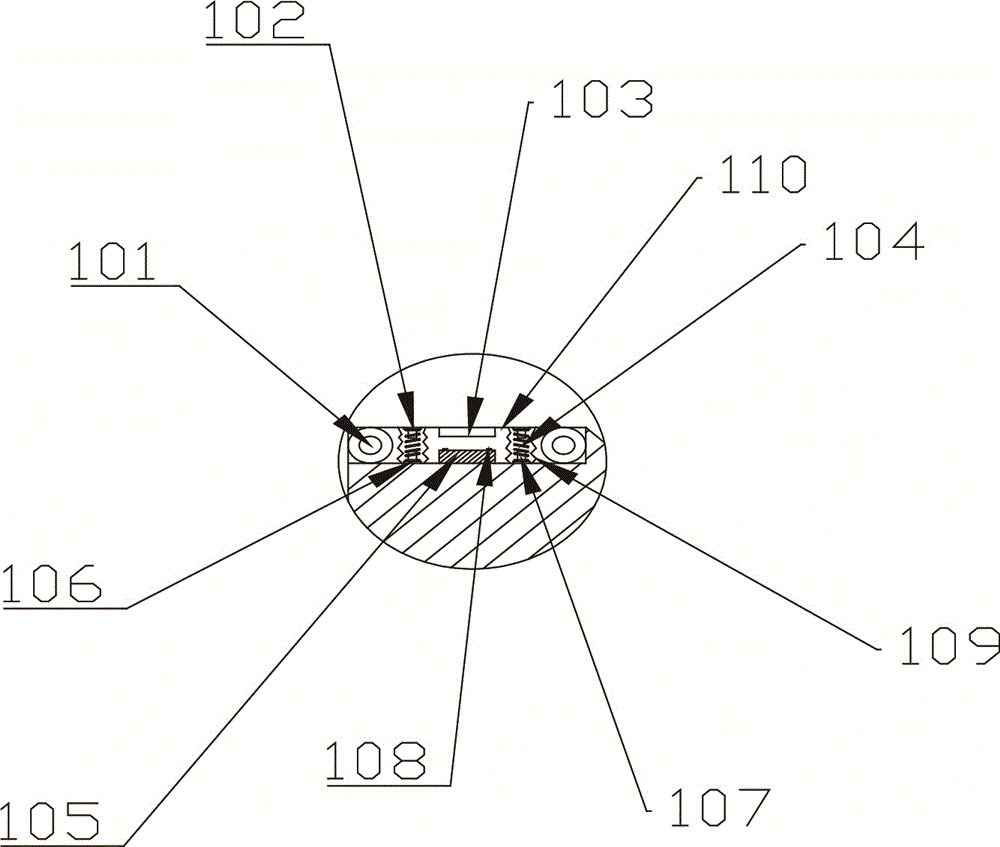

[0015] The technical solutions of the present invention will be further described below with reference to the drawings and embodiments.

[0016] See Figure 1 to Figure 3 , a powder grinding equipment, including a housing 4, a conveying device 10, a lifting device, and a grinding device. The conveying device 10 includes a conveyor belt 110, a driving roller 101 for driving the conveyor belt, and a support member for supporting the conveyor belt 110, and the support member includes a fixed plate 106 and a movable plate 102. The fixed plate 106 is arranged in parallel with the movable plate 102, the upper surface of the fixed plate 106 is provided with an electromagnet 105, the lower surface of the movable plate 102 is provided with an iron block 103, and the fixed plate 106 and the movable plate 102 There is also an elastic reset member between them; the transmission device of the present invention is provided with a supporting part, wherein the electromagnet 105 is intermitte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com