Keggin structural homopoly-anion-cation built catalyst as well as preparation method and application thereof

A technology of anions and cations and catalysts, applied in chemical instruments and methods, physical/chemical process catalysts, organic compounds/hydrides/coordination complex catalysts, etc., can solve complex preparation processes, high preparation and application costs, and recyclable Poor usability and other problems, to achieve the effect of simple preparation method, easy operation, and cheap preparation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

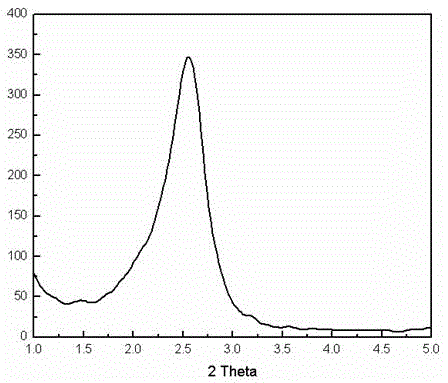

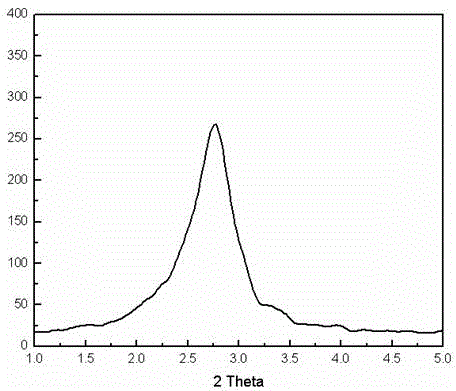

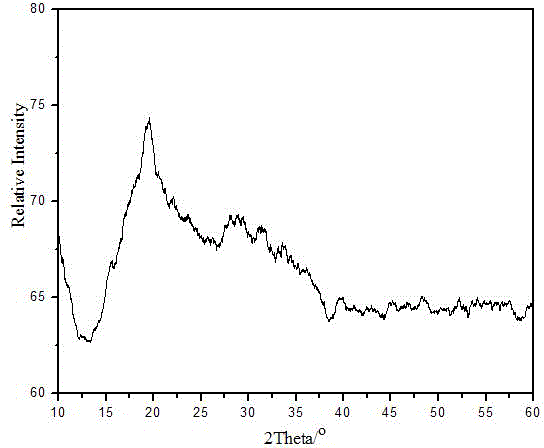

Image

Examples

Embodiment 1

[0050] According to the pairing ratio 1, pair ratio 2, pairing ratio 3, pairing ratio 4, pairing ratio 5, AL is prepared separately 13 -Thexane sulfonate, Al 13 -Thexanelzenzine sulfonate, alumin 13 -An lipide acid salt, Al 13 -Duocate or al 13 -Thexanel benzoate.With normal temperature, normal pressure and severe stirring, 0.1-10.0 G phosphoric acid is dissolved in a solution with 0.002 mol / L-0.02 mol / L in ethanol, which is called the above Al 13 One or more of the salt 0.5-10.0g is added to the above solution.60-100 ° C is dried for 4-24 h, and 100-200 ° C is baked 2-24 h.Prepared catalyst CAT-1.

Embodiment 2

[0052] According to the pairing ratio 1, pair ratio 2, pairing ratio 3, pairing ratio 4, pairing ratio 5, AL is prepared separately 13 -Thexane sulfonate, Al 13 -Thexanelzenzine sulfonate, alumin 13 -An lipide acid salt, Al 13 -Duocate or al 13 -Thexanel benzoate.At normal temperature, normal pressure and stirring, 0.5-10.0 G phosphoric acid solutions to N, n di metamimamide or second metamorphic 砜 to be made into a solution of 0.002 mol / L 0.02 mol / L.Tungsten acid 0.5-10.0 g is added to the above solution, and slowly steamed dry solvents N, n, nailianamide or second metamorphosis after 2-5 days.60-100 ° C is dried for 4-24 h, and 100-200 ° C is baked 2-24 h.Cat-2 is prepared.

Embodiment 3

[0054] According to the pairing ratio 1, pair ratio 2, pairing ratio 3, pairing ratio 4, pairing ratio 5, AL is prepared separately 13 -Thexane sulfonate, Al 13 -Thexanelzenzine sulfonate, alumin 13 -An lipide acid salt, Al 13 -Duocate or al 13 -Thexanel benzoate.With normal temperature, normal pressure and severe stirring, 0.1-10.0 G phosphoric phosphoric acid is dissolved in a solution with 0.002 mol / L-0.02 mol / L in ethanol. 13 -Thexanelsulfonate 0.5-10.0 g be added to the above solution.60-100 ° C is dried for 4-24 h, and 100-200 ° C is baked 2-24 h.Cat-3 is prepared.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com