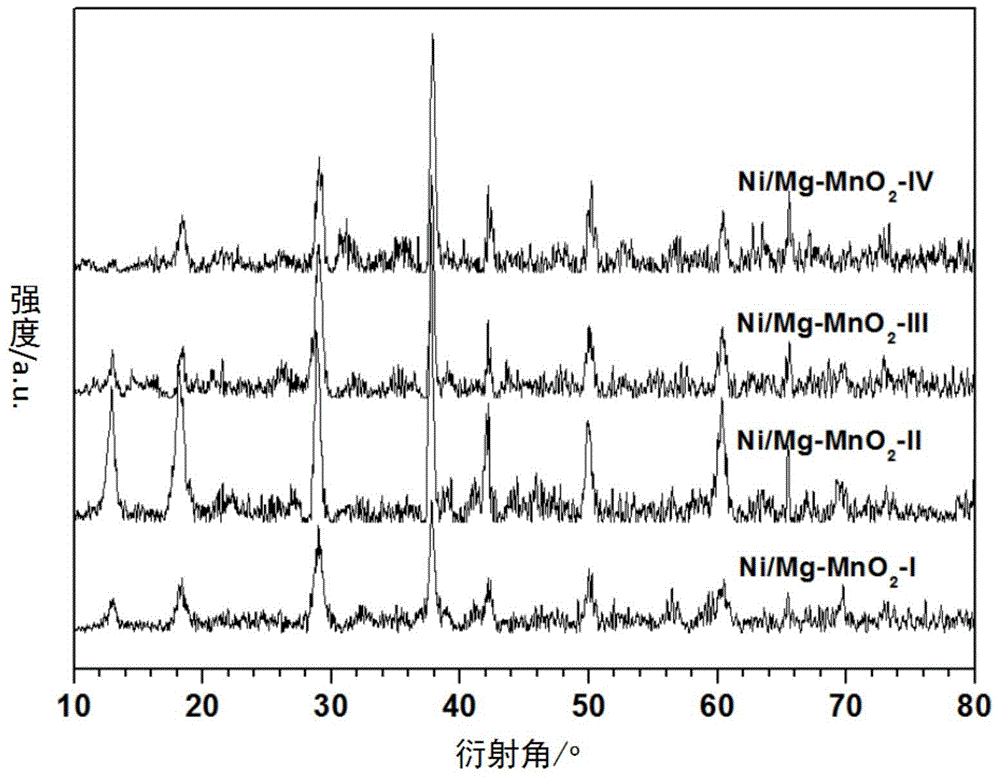

A kind of preparation method and application of α-manganese oxide supported nickel-magnesium catalyst

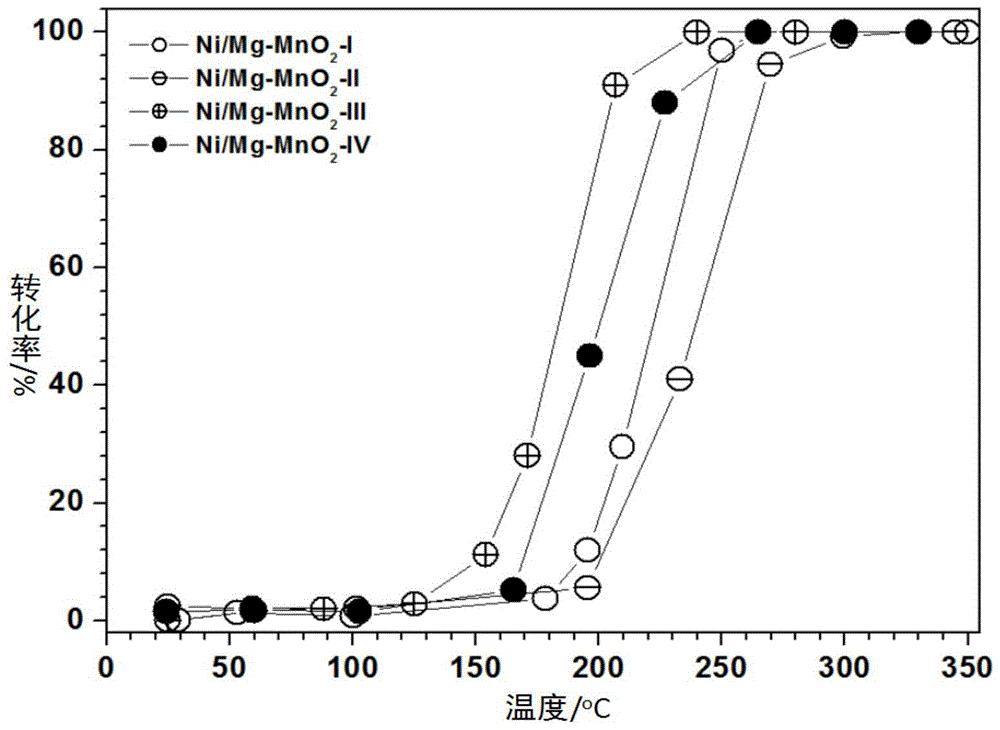

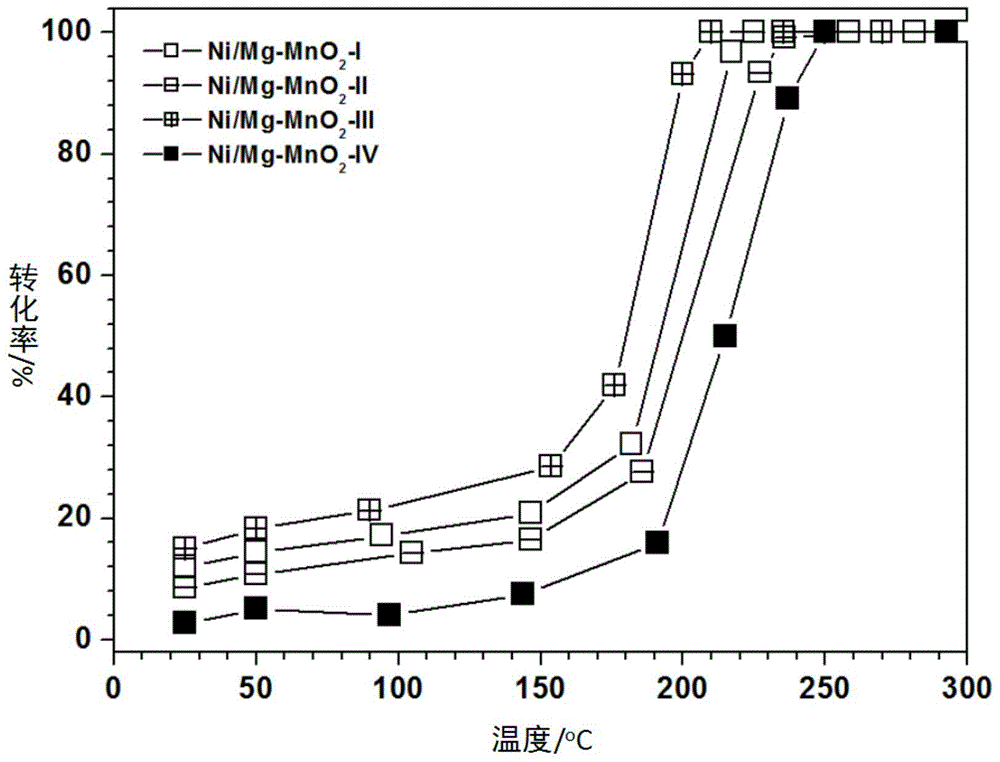

A technology for supporting nickel and catalyst is applied in the field of preparation of manganese oxide supported nickel-magnesium catalyst Ni/Mg-α-MnO2, and can solve the problem of high reaction temperature for completely catalyzing elimination of benzene series compounds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] (1) The preparation method of the above-mentioned catalyst provided by the present invention includes the following steps:

[0018] Mix the KAc solution and HAc solution into a buffer solution according to the molar ratio of KAc / HAc = 0.1, adjust the pH to about 3.74, and then add 0.01g of Mg(NO 3 ) 2 ·6H 2 O and 0.29gNi(NO 3 ) 2 ·6H 2 O is dissolved in the above 40ml acetate buffer solution. Add the above buffer solution containing metal salt to 24ml with a concentration of 1.0mol / LMn(Ac) 2 In the solution, mix well. Then the 120ml concentration was 0.1mol / LKMnO 4 The solution is dropped into the above mixed solution, in which KMnO 4 / Mn(Ac) 2 (Molar ratio)=0.5, stir for 2 hours, seal and age for 12 hours, reflux at 80°C for 20 hours, rotary steam for 3 hours until it becomes a powder, rinse with deionized water to neutrality, and dry at 100°C for 10 hours to obtain a black precursor Body, and then ground into powder. Take the above precursor and pure ethanol in a ratio ...

Embodiment 2

[0021] (1) The preparation method of the above-mentioned catalyst provided by the present invention includes the following steps:

[0022] Mix the KAc solution and HAc solution into a buffer solution at a molar ratio of KAc / HAc=1.0, adjust the pH to about 4.74, and then add 0.03g of Mg(NO 3 ) 2 ·6H 2 O and 1.50gNi(NO 3 ) 2 ·6H 2 O is dissolved in the above 40ml acetate buffer solution. Put 0.5g of PVP (molecular formula (C 6 H 9 NO) n , Molecular weight 1000) dissolved in 28.5ml, concentration is 1.5mol / LMn(Ac) 2 In solution. Add the above buffer solution containing metal salts to this solution and mix well. Then the concentration of 150ml is 0.2mol / LKMnO 4 The solution is dropped into the above mixed solution, in which KMnO 4 / Mn(Ac) 2 (Molar ratio)=0.7, stirring for 2 hours, sealing and aging for 12 hours, refluxing at 80°C for 20 hours, rotary steaming for 3 hours until it becomes a powder, rinse with deionized water to neutrality, and dry at 100°C for 10 hours to obtain black...

Embodiment 3

[0025] (1) The preparation method of the above-mentioned catalyst provided by the present invention includes the following steps:

[0026] The KAc solution and the HAc solution were mixed into a buffer solution at a molar ratio of KAc / HAc=5.0, adjusted to pH 5.4, and then 0.04g of Mg(NO 3 ) 2 ·6H 2 O and 2.50gNi(NO 3 ) 2 ·6H 2 O is dissolved in the above 40ml acetate buffer solution. Put 1.5g of PVP (molecular formula (C 6 H 9 NO) n , Molecular weight 1000) dissolved in 37.5ml, concentration is 1.5mol / LMn(Ac) 2 In solution. Add the above buffer solution containing metal salts to this solution and mix well. Then the concentration of 150ml is 0.3mol / LKMnO 4 The solution is dropped into the above mixed solution, in which KMnO 4 / Mn(Ac) 2 (Molar ratio)=0.8, stirring for 4 hours, sealing and aging for 12 hours, refluxing at 120°C for 26 hours, rotary steaming for 4 hours until it becomes a powder, rinse with deionized water to neutrality, and drying at 140°C for 12 hours to obtain bla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com