Bract leaf returning corn harvester

A harvester and bract technology, which is used in harvesters, cutters, crop processors, etc., can solve the problems of bract blocking, small processing capacity, and easy blocking, so as to avoid retention and blockage, improve processing capacity, reduce The effect of small blocking surfaces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

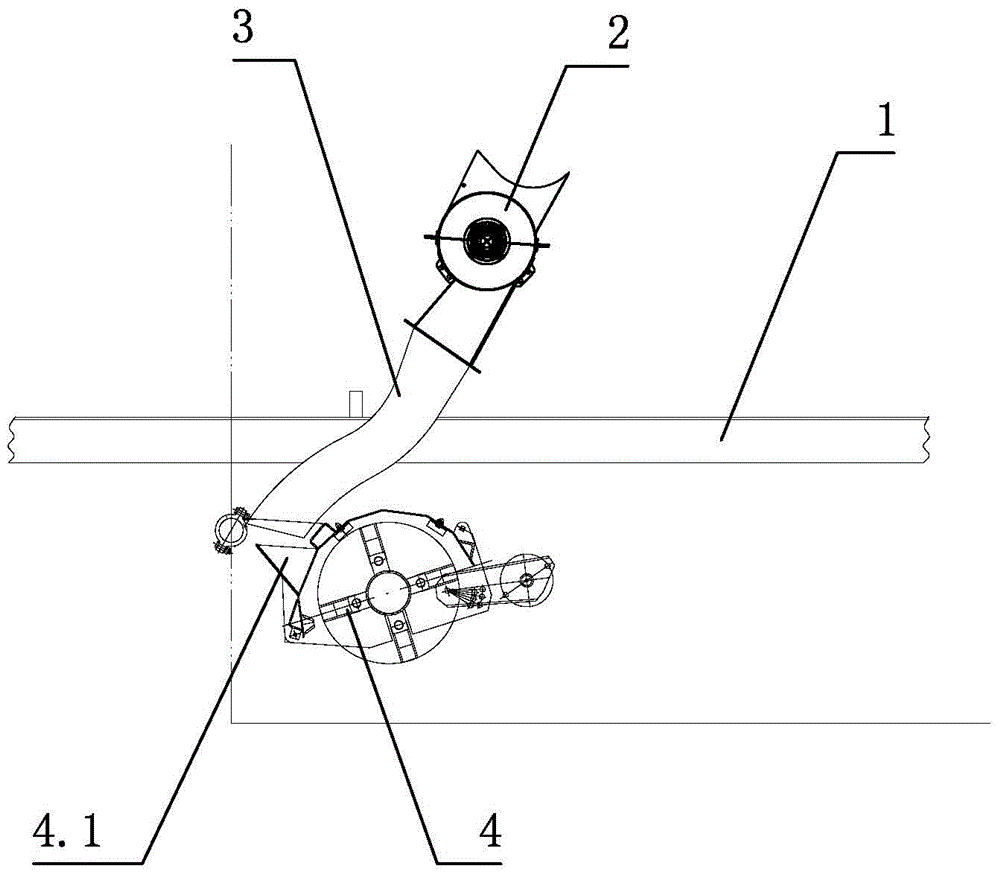

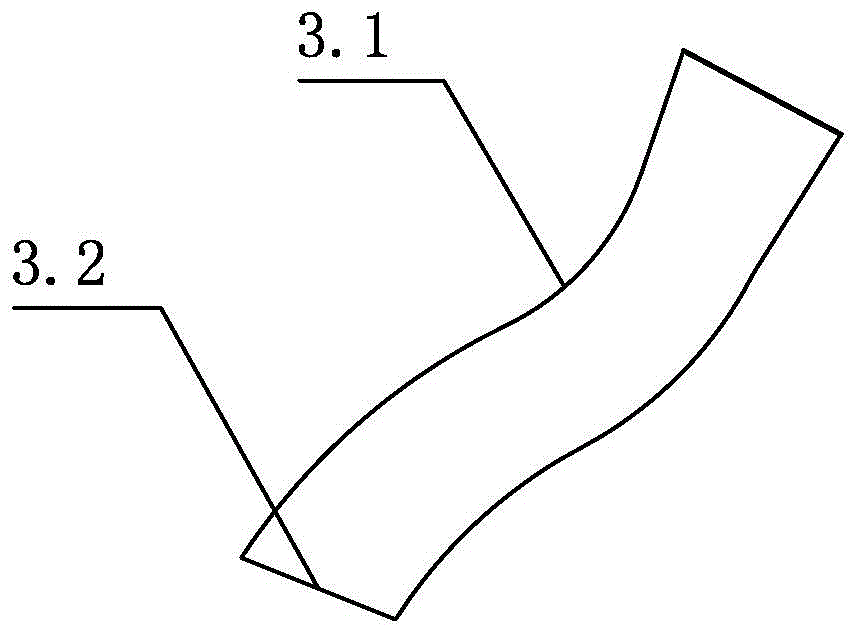

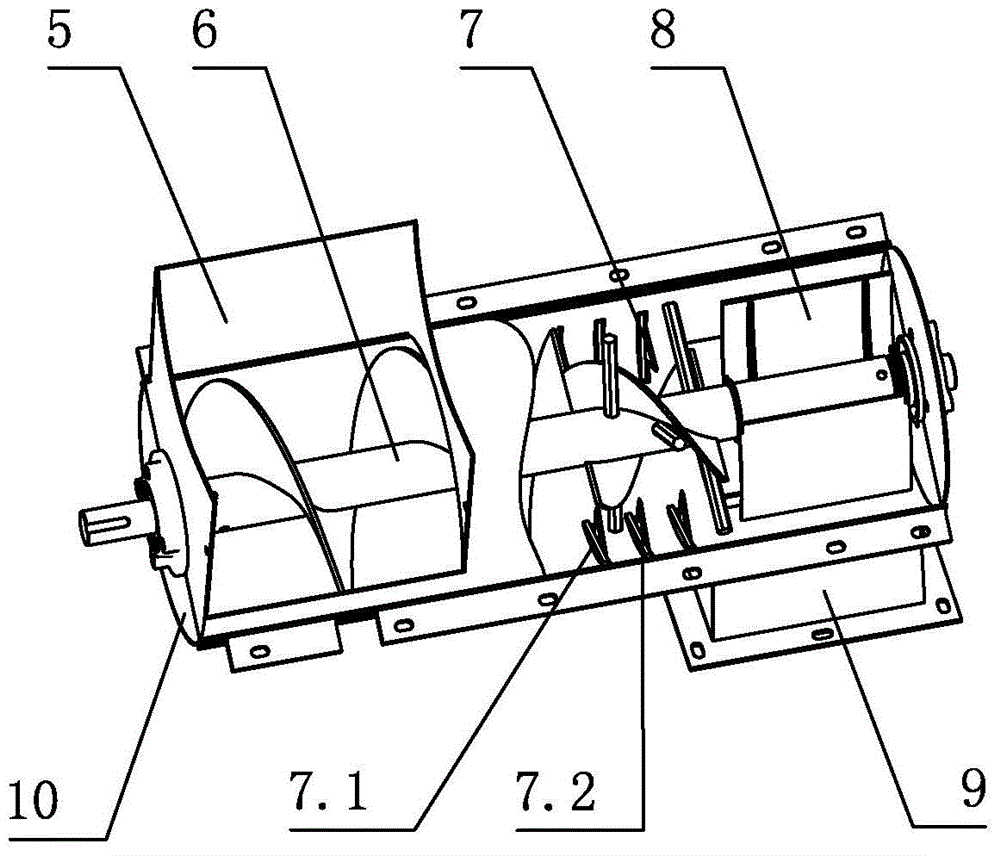

[0023] Such as Figure 1~2 As shown, the bract returning corn harvester includes a vehicle frame 1 and a bract cutting device 2 and a straw crushing device 4 arranged on the frame 1. The bract cutting device 2 is arranged above the straw crushing device 4. The bottom of the leaf chopping device 2 is connected to the discharge pipe 3, and the discharge port 3.2 of the discharge pipe 3 is arranged in the gap between the straw crushing device 4 and the front frame 1, and is connected to the discharge port 4.1 of the straw crushing device 4. correspond. The bract shredding device 2 cuts the bract into strips, and the shredded bract falls into the straw crushing device 4 through the discharge pipe 3 for further crushing. In a limited space, the trajectory of the discharge pipe 3 is designed as a curve, and in order to avoid blocking during blanking, the cur...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap