Winding structure and transformer assembly with same and transformer

A winding structure and transformer technology, applied in the field of transformers, can solve the problems of large potential difference of copper wires, loss of efficiency, complicated winding process, etc., and achieve the effect of less potential difference between copper wires, reducing power loss and simple winding process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

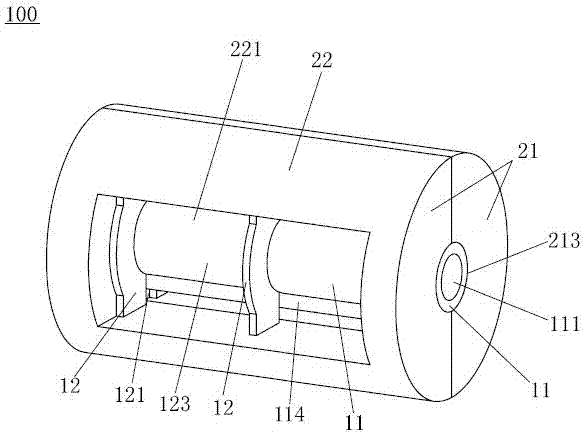

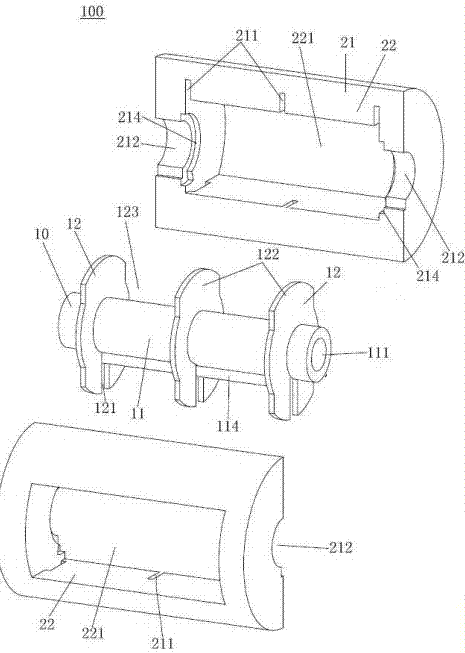

[0029] A transformer 1000 of the present invention includes a winding structure 10 , a winding 200 and an iron core 300 . The transformer assembly includes a winding structure 10 and a casing 20 .

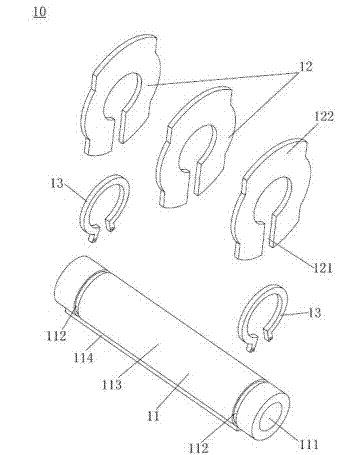

[0030] refer to figure 1 and figure 2 , the winding structure 10 includes a bobbin 11 and a conductive sheet 12 . The bobbin 11 has a channel 111 extending longitudinally through the bobbin 11 , a conductive sheet area 113 is formed between two ends of the bobbin 11 , and a bobbin protrusion 114 protrudes from the lower end of the conductive sheet area 113 . The conductive sheet 12 is ring-shaped, and an opening 121 is opened at the lower end of the conductive sheet 12 , and pins 122 for soldering with a circuit board may be provided on both sides of the conductive sheet 12 corresponding to the opening 121 . A curved edge protrusion 122 protrudes from an end of the conductive sheet 12 opposite to the opening 121 . The conductive sheet 12 is clamped in the conductive sheet area...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com