Non-classical nonlinear detection method aiming at microcrack in non-uniform members

A detection method and a technology of variable cross-section, which are applied in the direction of material analysis using acoustic wave emission technology, and can solve the problem that the width and size cannot be determined.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

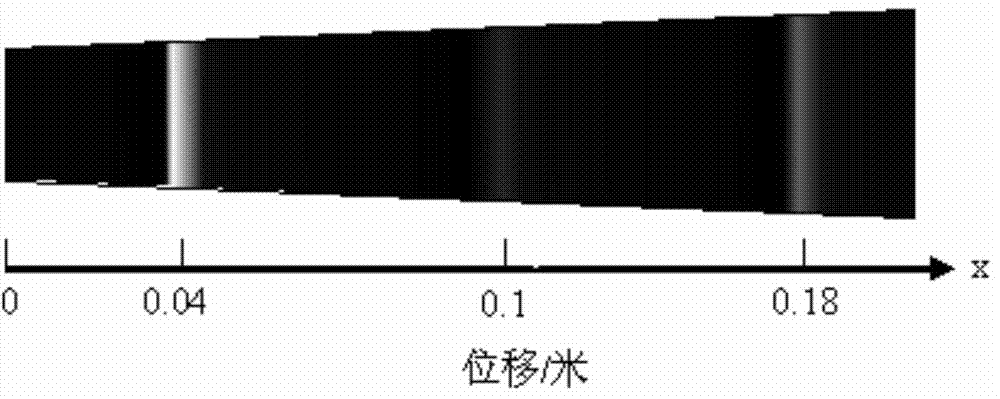

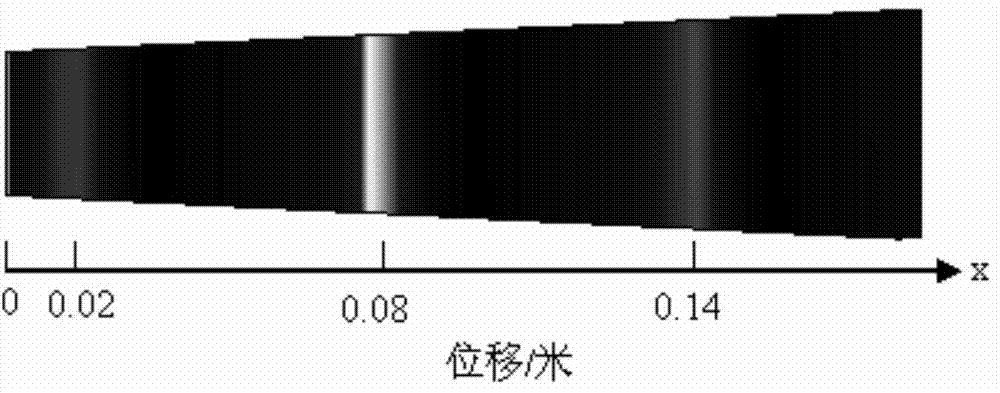

[0031] The present embodiment selects 3 tapered rods with variable cross-section in parallel: the length L is 0.2 meters, and the cross-sectional area S(x)=(1+x / 10) 2 S 0 ;Material density ρ=7.8×10 3 kg / m 3 , longitudinal sound velocity c=6×10 3 m / s, S(0) is 2.5×10 -3 m 2 , the position of the center of the micro-crack is x 1 = 0.04, 0.08 and 0.12 meters, the micro-crack width d is 0.5 mm for the sample to be tested;

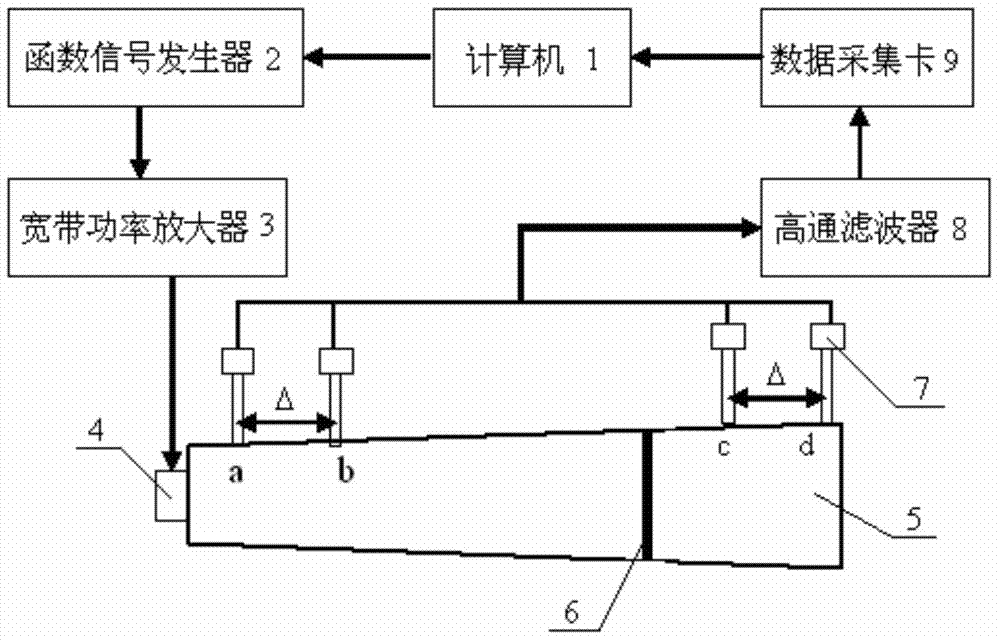

[0032] The structural diagram of the detection system adopted in this embodiment is as follows: figure 1 Shown: including computer 1, function signal generator 2, broadband power amplifier 3, energy-concentrating transducer 4, four laser displacement sensors 7, high-pass filter 8 and data acquisition card 9, described energy-concentrating transducer 4. Coupling and contacting with one end of the variable-section member 5 to be measured, the laser beam centers of the four laser displacement sensors 7 are respectively aligned with the left end position (x=0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com