Energy-saving furnace body structure of large-type pit furnace

A furnace body structure and well-type furnace technology, which is applied in the field of large-scale well-type furnace energy-saving furnace body structure, can solve the problems of affecting the life of large-scale well-type furnaces, poor heating uniformity, and poor heat preservation effect, so that it is not easy to dissipate heat , improve life, reduce the effect of heat radiation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to deepen the understanding of the present invention, the present invention will be further described below in conjunction with the accompanying drawings and embodiments, which are only used to explain the present invention and do not limit the protection scope of the present invention.

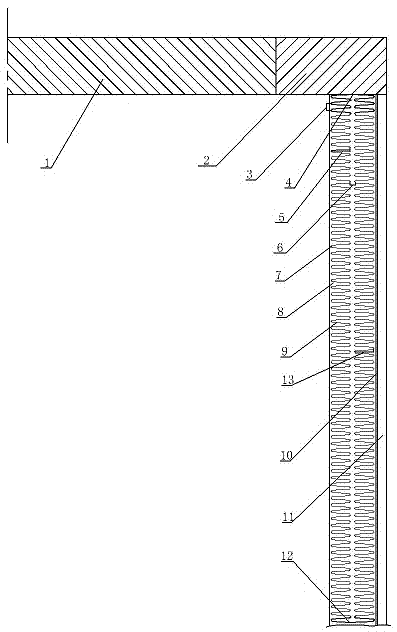

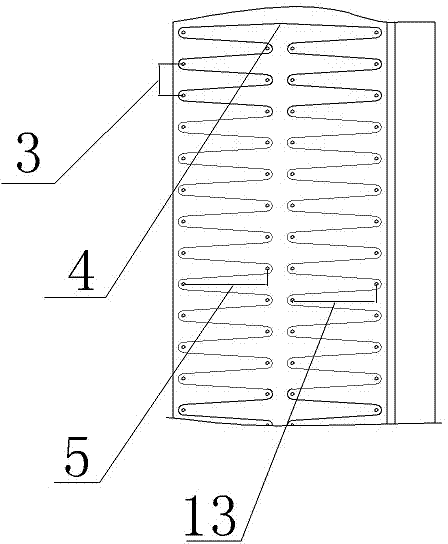

[0018] like figure 1 and figure 2 As shown, a large well-type furnace energy-saving furnace body structure includes a furnace lining 8, a heating element 9, and a furnace shell 11. The furnace shell 11 is set on the outermost layer of the furnace body structure, and the furnace lining 8 is connected to the furnace shell 11. A plurality of heating elements 9 are provided, and four rows of fixing pieces 7 are arranged staggeredly in the furnace lining 8, and each heating element 9 is spirally and evenly wound along the leftmost two rows of fixing pieces 7 and the rightmost two rows of fixing pieces 7 respectively. The two sets of spiral heating elements 9 of each heating elem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com