Lifting device and automatic handling system thereof

A lifting device and handling system technology, applied to cranes, transportation and packaging, trolley cranes, etc., can solve problems such as position deviation, elastic fatigue, abnormality of unmanned vehicles, etc., and achieve the effect of reducing failures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example ]

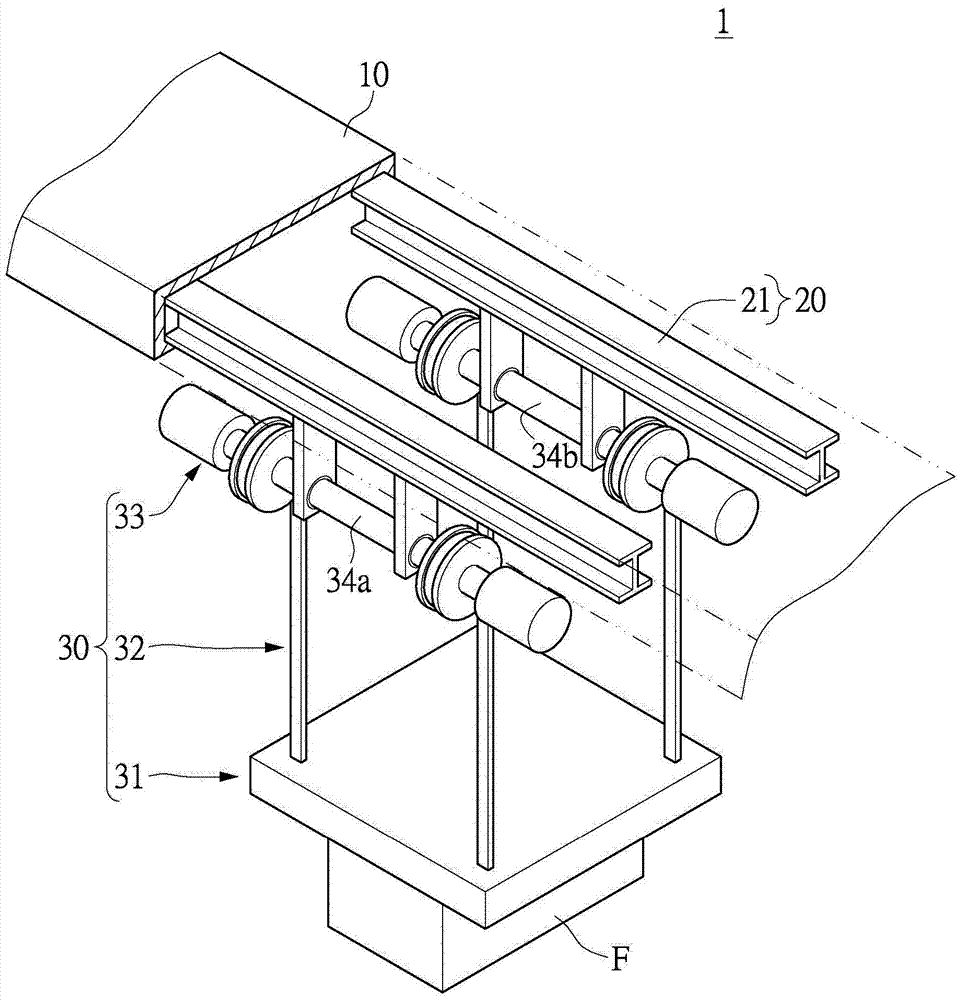

[0050] see figure 1 , is a perspective view of the automated handling system according to the first embodiment of the present invention. The automatic transport system 1 of this embodiment includes a suspended track 10 , at least one automatic transport vehicle 20 and at least one lifting device 30 . Wherein the suspended track 10 is suspended on the ceiling (not shown) in the semiconductor manufacturing factory, the automatic transport vehicle 20 is movably assembled on the suspended track 10, and the lifting device 30 is suspended on the automatic transport vehicle 20 . Accordingly, the automatic transfer vehicle 20 can run along the suspended track 10, and transfer a wafer box (FOUP) F loaded with multiple wafers from a loading port (Load port) on a machine to the Another loading end (not shown), or transfer the wafer cassette F to another machine (not shown) after the predetermined process is completed on the same machine.

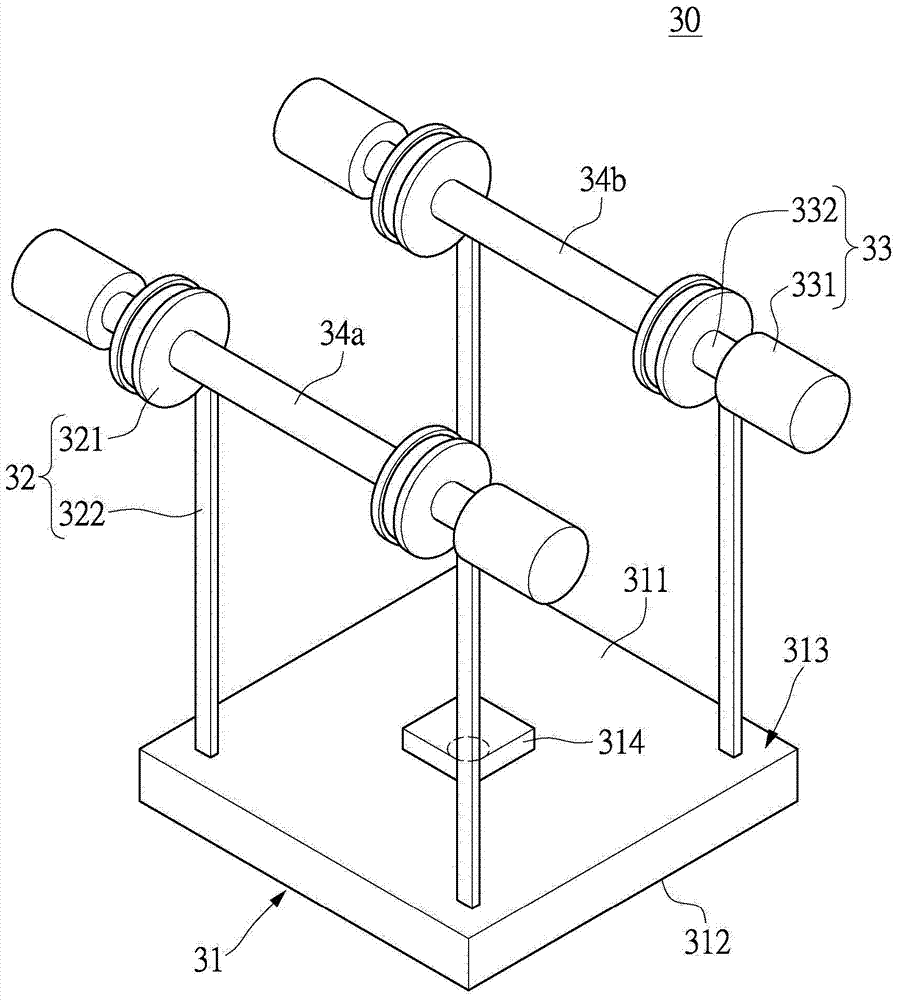

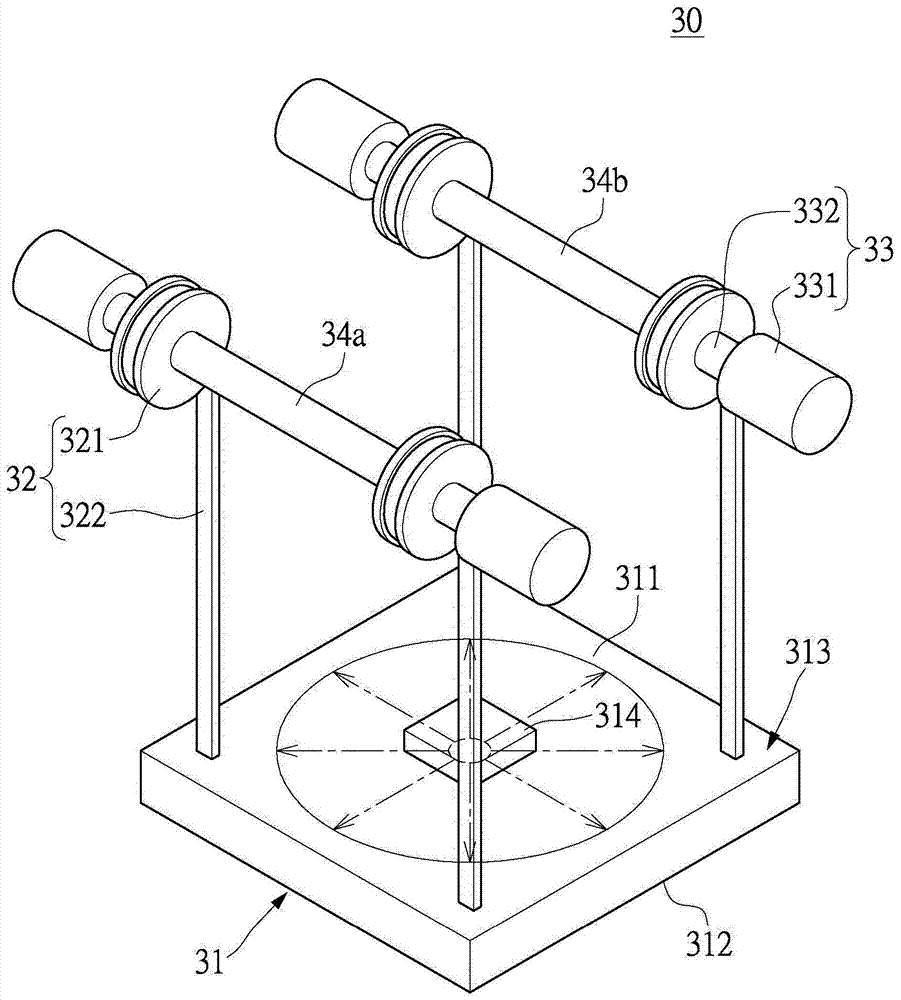

[0051] Please refer to figure 2 , is a pers...

no. 2 example ]

[0060] see Image 6 , is a perspective view of the lifting device of the second embodiment of the present invention. As shown in the figure, the difference of this embodiment is that the automatic transfer vehicle 20' also has a second drive assembly 22, a sliding frame 23 is provided under the slide rail 21, and a lifting base 31' is further provided with a Visual detection device 315. Therefore except the automatic pallet truck 20' and the lifting base 31', all the other component numbers are the same as those of the first embodiment.

[0061] Please refer to Figure 7 and 8 , is a schematic diagram of alignment between the lifting base and the wafer cassette according to the second embodiment of the present invention. In this specific embodiment, an identification mark M opposite to the lifting base 31' is provided on the top of the wafer box F for identification by the visual inspection device 315. In order to achieve the above-mentioned purpose, the sliding frame 23 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com