Adhesive

A technology of adhesive and adhesive layer, which is applied in the direction of adhesive type, adhesive, polyurea/polyurethane adhesive, etc., and can solve the problems of poor wettability of surface protection film, glue residue, and air bubbles, etc. , to achieve the effect of excellent adhesive reliability and excellent reworkability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

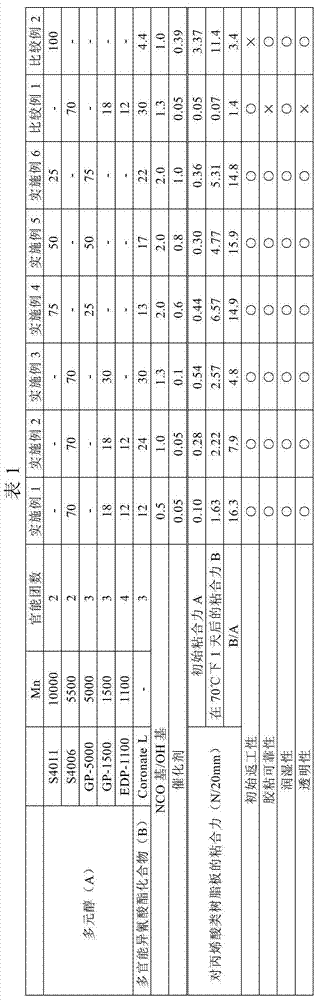

[0140] As the polyol (A), 70 parts by weight of PREMINOL S4006 (manufactured by Asahi Glass Co., Ltd., Mn=5500) as a polyol having two OH groups, and SANNIX GP-1500 as a polyol having three OH groups ( Sanyo Chemicals Co., Ltd., Mn=1500) 18 parts by weight, EDP-1100 (manufactured by ADEKA Corporation, Mn=1100) which is a polyhydric alcohol having four OH groups, 12 parts by weight, polyfunctional isocyanate compound (B) Trimethylolpropane / toluene diisocyanate trimer adduct (manufactured by Nippon Polyurethane Industry Co., Ltd., trade name: Coronate L) 12 parts by weight, catalyst (manufactured by Nippon Chemical Industry Co., Ltd., trade name: Nasem No. 2 Iron) 0.05 parts by weight of ethyl acetate as a diluting solvent was blended so that the solid content concentration became 50% by weight, and stirred with a disperser to obtain a polyurethane-based adhesive composition. The resulting polyurethane-based adhesive composition was coated onto a base material "Lumirror S10" (th...

Embodiment 2

[0144]Except that the usage-amount of the polyfunctional isocyanate compound (B) was set to 24 parts by weight (NCO group / OH group=1.0), it carried out similarly to Example 1, and obtained the surface protection film (2) which has an adhesive layer . In addition, the obtained surface protection film (2) can also be used as an adhesive sheet.

[0145] The evaluation results are shown in Table 1.

Embodiment 3

[0147] As the polyol (A), 70 parts by weight of PREMINOL S4006 (manufactured by Asahi Glass Co., Ltd., Mn=5500) which is a polyol having two OH groups and SANNIX GP-1500 (manufactured by Sanyo Co., Ltd.) which is a polyol having three OH groups are used. Manufactured by Chemical Industry Co., Ltd., Mn=1500) 30 parts by weight, the usage-amount of polyfunctional isocyanate compound (B) is set to 30 parts by weight (NCO group / OH group=1.3), and the usage-amount of catalyst is set to 0.1 Except that, it carried out similarly to Example 1, and obtained the surface protection film (3) which has an adhesive layer. In addition, the obtained surface protection film (3) can also be used as an adhesive sheet.

[0148] The evaluation results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| haze | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com