Liquid crystal display pixel structure and manufacturing method thereof

一种像素结构、液晶显示的技术,应用在仪器、非线性光学、光学等方向,能够解决效果不佳、色偏严重等问题,达到改善色偏现象、色偏现象改善、高穿透率表现的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] In order to further illustrate the technical means adopted by the present invention and its effects, the following describes in detail in conjunction with preferred embodiments of the present invention and accompanying drawings.

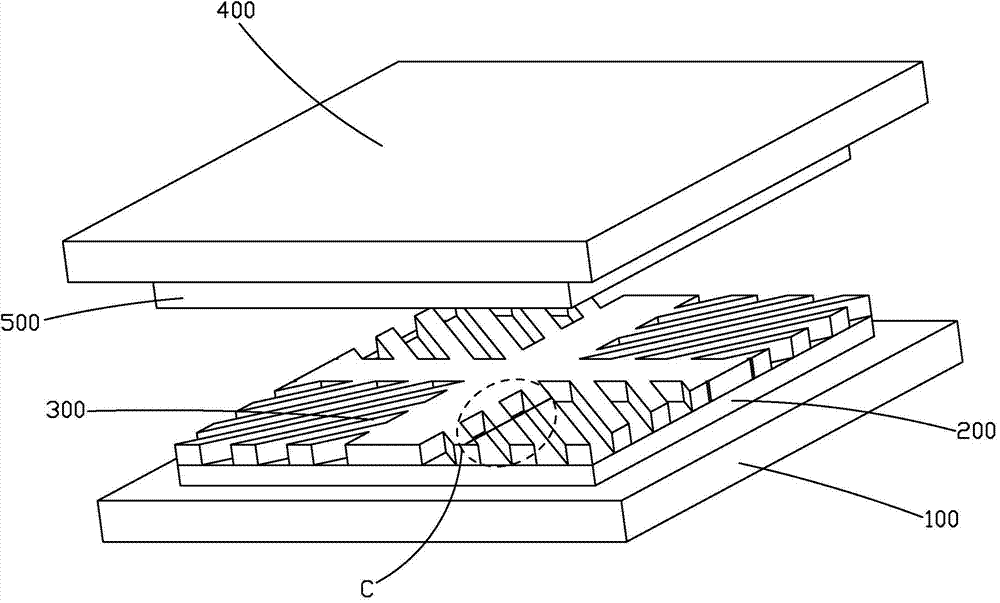

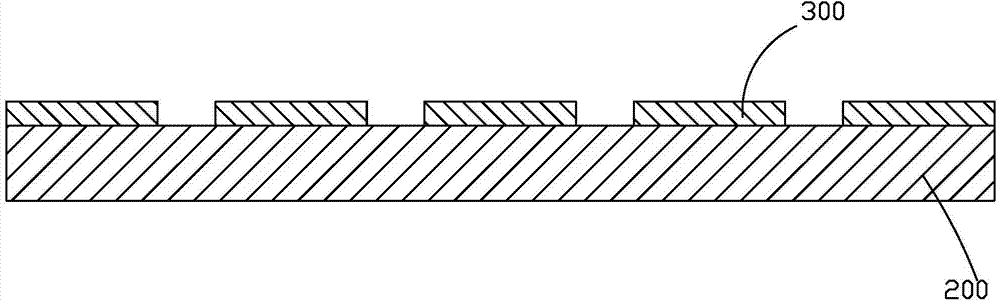

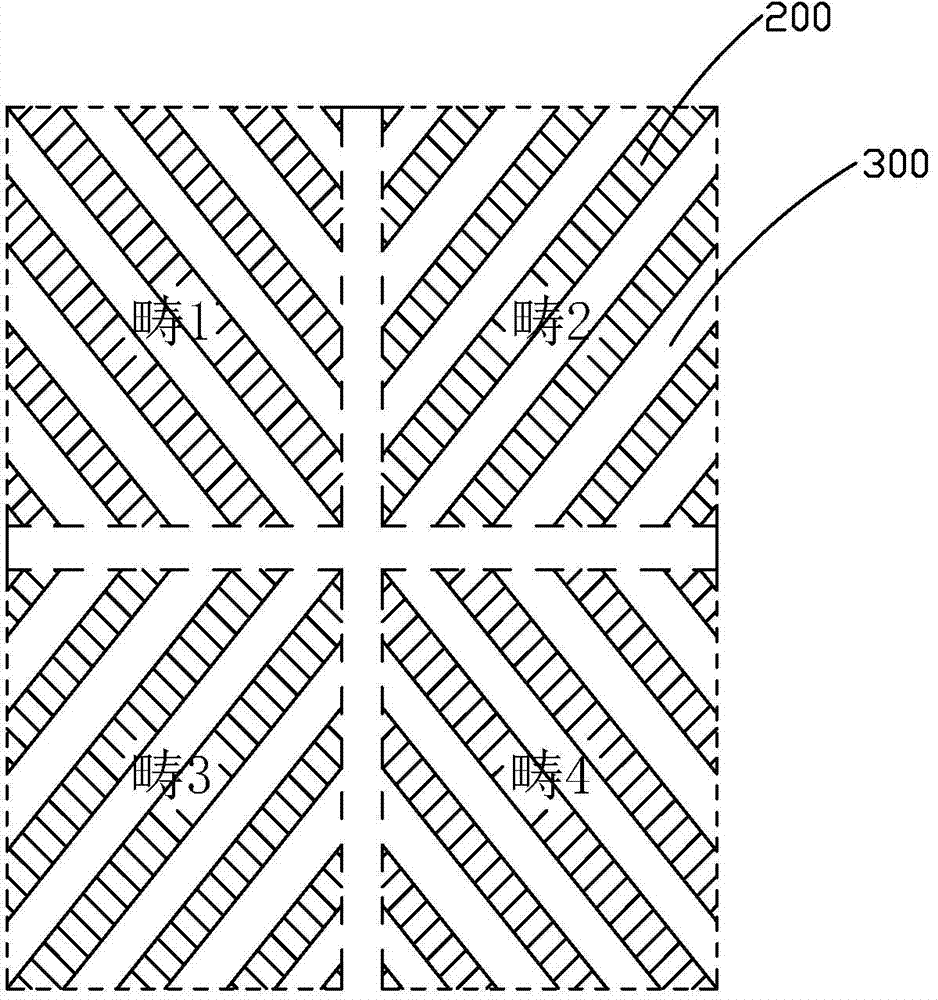

[0047] Please also refer to Fig. Image 6 , Figure 7 , Figure 8 , is the first embodiment of the liquid crystal display pixel structure of the present invention, including: a lower substrate 1, a passivation layer 2 arranged on the upper surface of the lower substrate 1, a pixel electrode 3 arranged on the passivation layer 2, an upper substrate 4, and The common electrode 5 provided on the lower surface of the upper substrate 4 .

[0048]The pixel electrode 3 is an ITO electrode, and the common electrode 5 is an ITO electrode. Each pixel is provided with multiple domains; in one pixel, the passivation layer 2 includes at least two trench structures with different depths, and the pixel electrode 3 covers the trench structures continuously...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com