Test bed of resin transfer technology and test method of test bed

A test bench and resin technology is applied in the field of test benches to achieve the effect of reasonable structure and reduction of residual resin.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

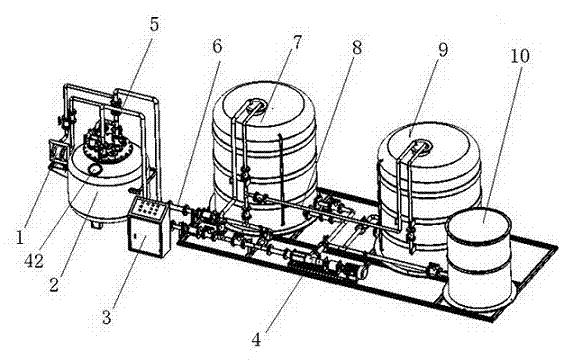

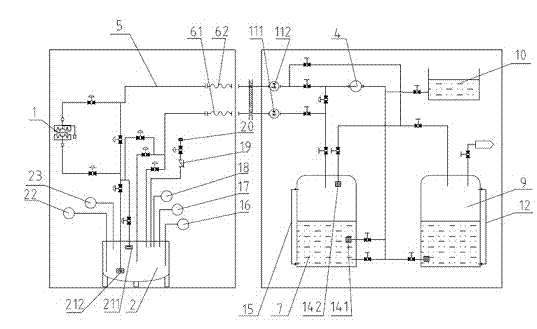

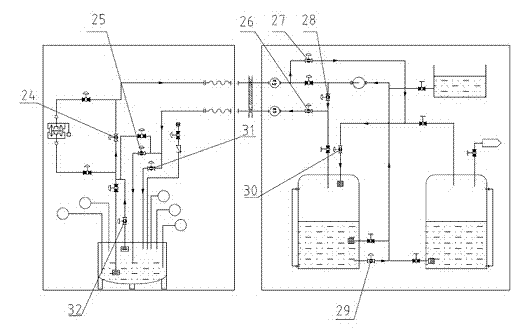

[0047] The invention discloses a test bench for resin transfer technology, as attached figure 1 As shown, it includes: a resin storage tank 2 that can store waste resin for simulating a shielded transfer device, the resin storage tank 2 is a pressure vessel, and an observation window is arranged above it; it also includes a station for simulating a nuclear island / SRTF The resin transfer tank 7, the resin flushing and draining tank 9, the resin mixing tank 10, and the metal hose used to connect the simulated shielding transfer device to the nuclear island / SRTF station.

[0048] The resin storage tank 2 is provided with an instrument assembly, and the instrument assembly includes a low liquid level gauge 16 and a pressure sensor 22 respectively arranged on both sides of the lower part of the resin storage tank 2; There are a high liquid level gauge 18 and a resin level gauge 17 on both sides of the inner upper part, and a thermal conductivity flow switch 23 arranged outside the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com