Device and method for hydraulic structure deformation distribution type optical fiber monitoring

A technology of distributed optical fiber and monitoring device, which is applied to measurement devices, optical devices, instruments, etc., can solve problems such as poor durability, difficult circuit setting, and difficult construction and layout, so as to improve reliability and engineering practicability and reduce engineering costs. Monitoring and testing costs, the effect of facilitating project transportation and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

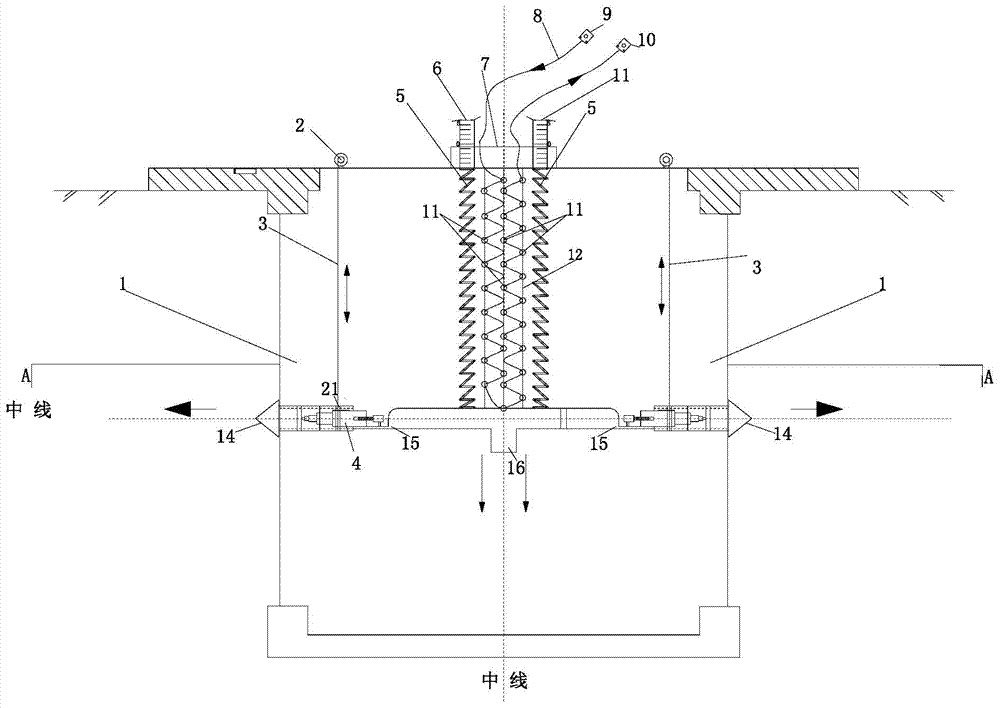

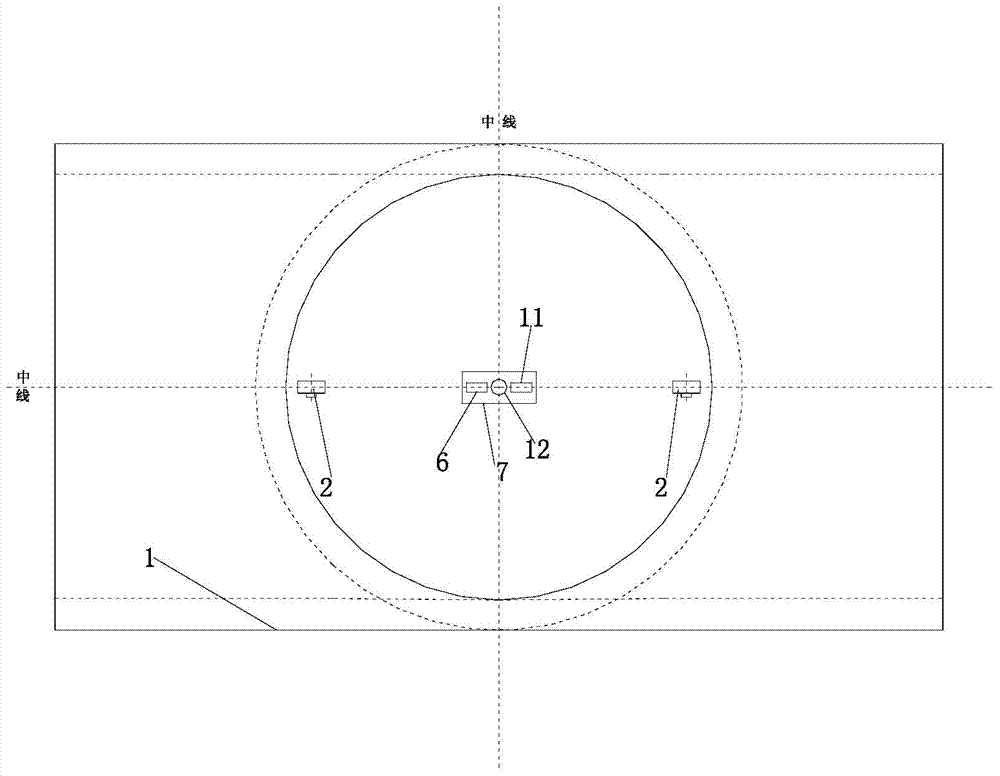

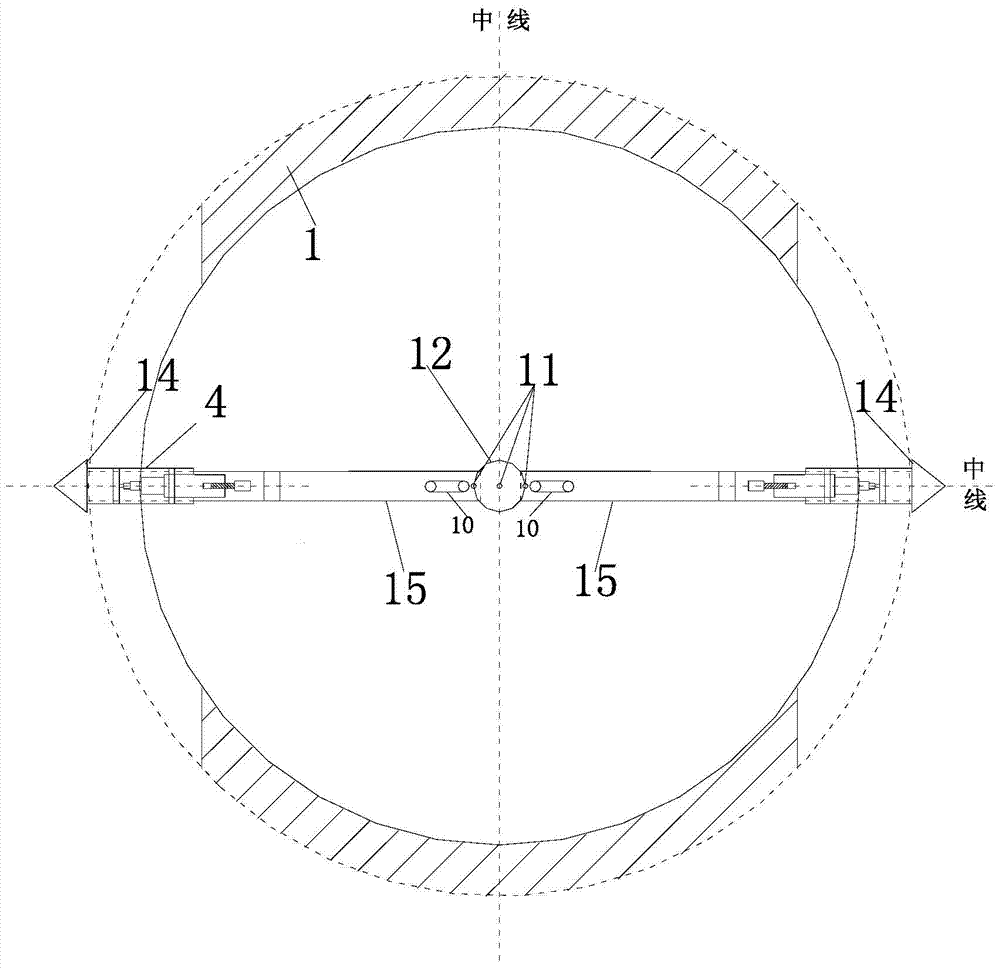

[0022] The present invention will be further described below in conjunction with the accompanying drawings.

[0023] Such as Figure 1 to Figure 4 As shown, a distributed optical fiber monitoring device for hydraulic structure deformation of the present invention includes a bottom-through shaft 1, a shifting table 15 is installed in the bottom-through shaft 1, and two sides of the shifting table 15 are symmetrically installed with The drill drive device 4 is connected with the tapered drill bit 14; the drill drive device 4 on both sides of the shifting table 15 is respectively connected with the lifting rope 3, and the lifting rope 3 is wound on the take-up reel, and the take-up reel is installed on the gear On the shaft 2, the gear on the gear shaft 2 meshes with the rotating gear, and the rotating gear is driven by a motor; the middle part of the shifting table 15 is connected with one end of a pair of symmetrically installed springs, and the other end of the spring is hinge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com