Universal flue windproof cap

A windproof cap and flue technology, which is applied in the direction of combustion product treatment, combustion method, exhaust gas device, etc., can solve the problems of low work efficiency, heavy workload, increased cost, etc., and achieve convenient installation and maintenance, smooth smoke exhaust, Make easy effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

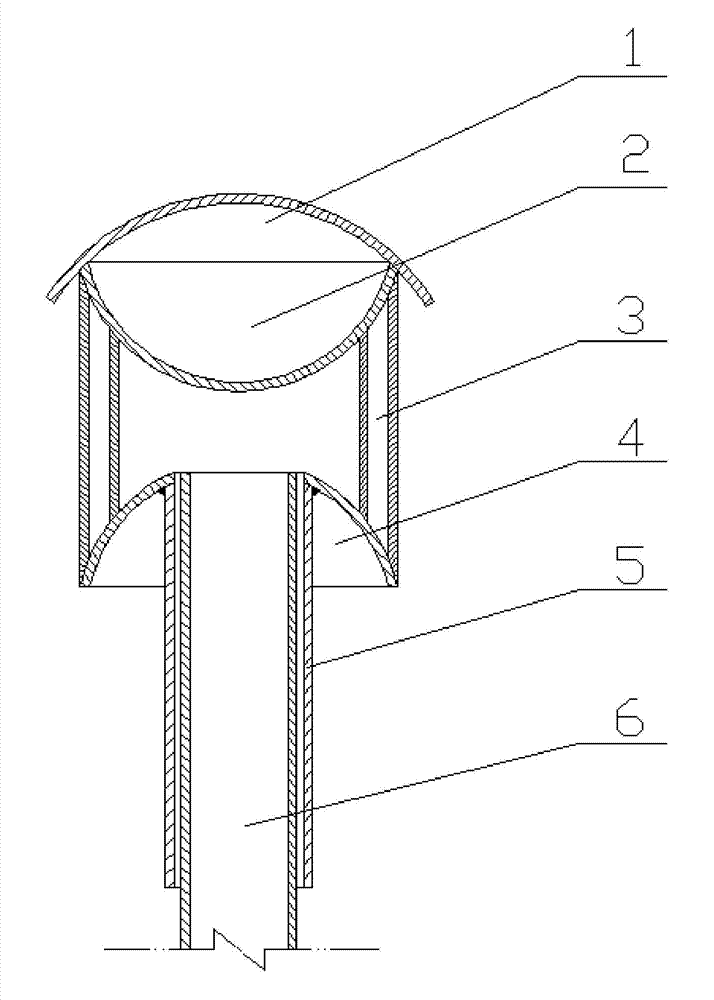

[0012] figure 1 It is a flue universal windproof cap, which is composed of an upper ball 2, a lower ball 4, a strut 3, a convex rain cover 1 and a sleeve 5. The upper ball 2 and the lower ball 4 are both bowl-shaped, and 4 struts 3 connect the upper ball and the lower ball. The upper ball 2 is located directly above the lower ball 4 and the upper ball and the lower ball are at the bottom Set against the bottom. The last ball gap 2 is welded with the convex surface rainproof cover 1 above. A circular smoke outlet is provided at the center of the lower ball gap 4, and the smoke outlet is welded with a sleeve pipe 5 whose diameter is slightly larger than that of the chimney pipe 6 and allows the sleeve pipe to be inserted into the chimney pipe 6.

[0013] When making it, first use two bowl-shaped spherical bodies of thin iron, and then use four iron pipes with a diameter of 19mm to be symmetrically arranged around the two spherical bodies and weld them to form a bottom-to-botto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com