A ten-speed hydraulic transmission for a vehicle

A technology of hydraulic transmission and hydraulic torque converter, which is applied in the field of mechanical transmission, can solve the problems of complex structure of hydraulic transmission device, large volume and weight of the whole machine, and influence on the quality of vehicle shifting, so as to broaden the range of efficacy, The ratio is reasonable and the effect of improving the smoothness of shifting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical solution of the present invention is further described below in conjunction with the accompanying drawings, but the scope of protection is not limited to the description.

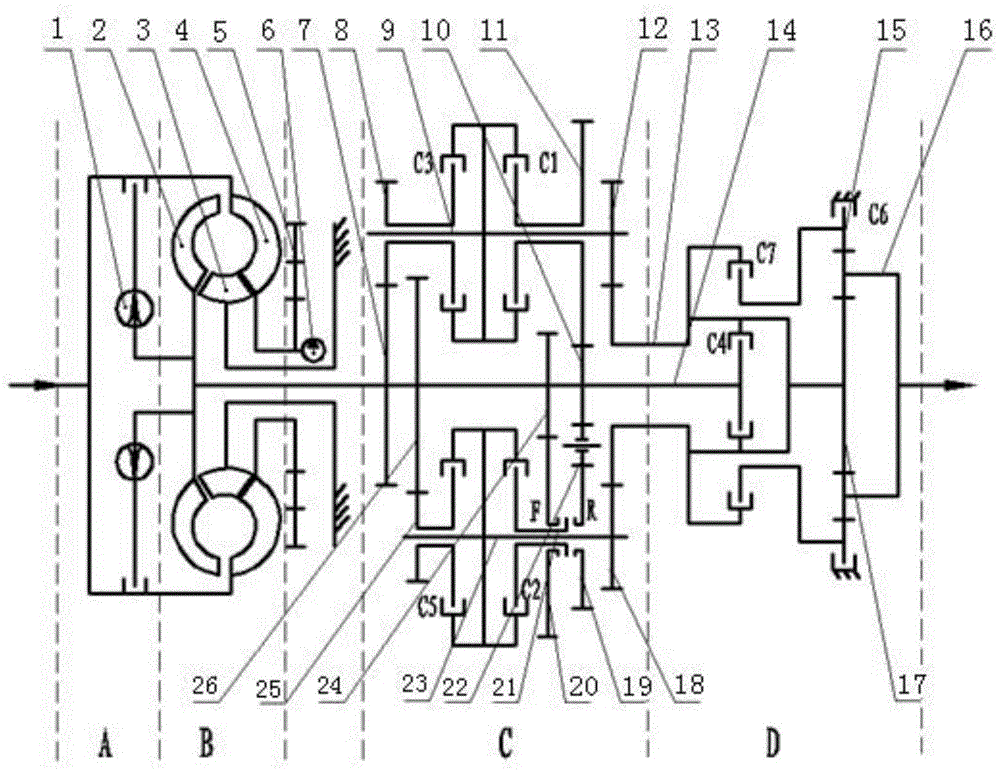

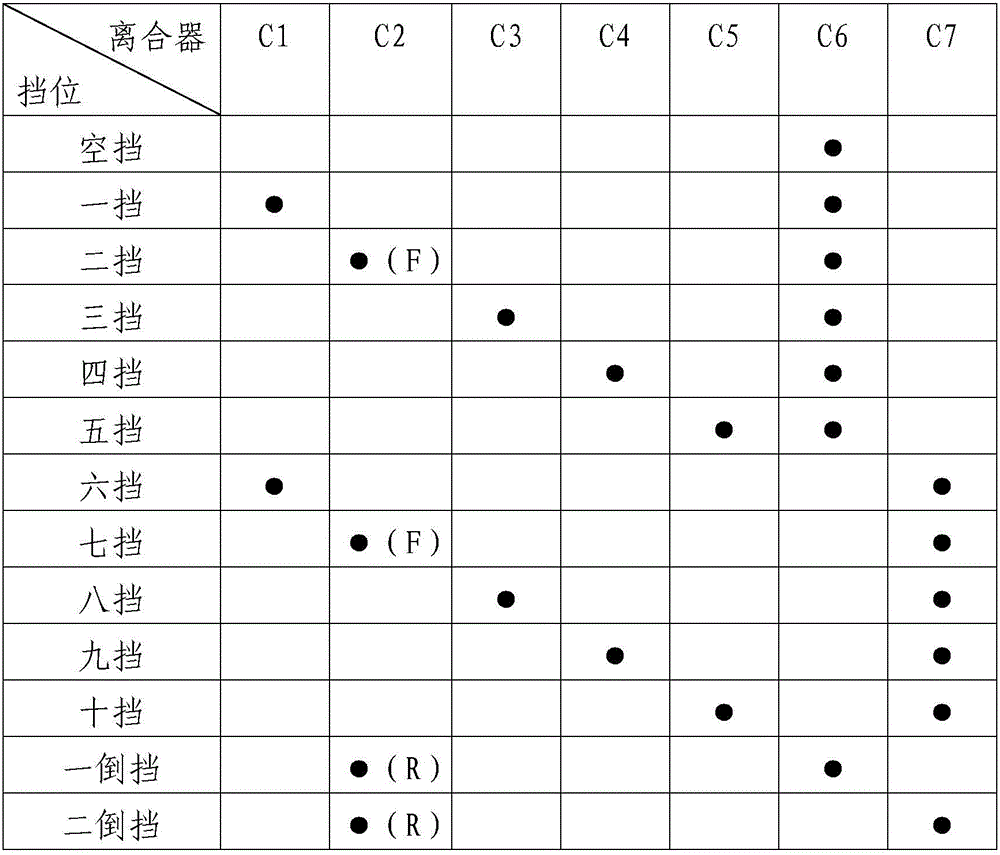

[0023] Such as figure 1 As shown, a ten-speed hydraulic transmission for a vehicle according to the present invention includes a power output device 5, a lock-up and damping clutch assembly A, a hydraulic torque converter B, a main shaft 14, a main gearbox C, an auxiliary transmission Box D, the first parallel shaft 9 and the second parallel shaft 23, the output end of the power output device 5 is connected to the locking and damping clutch assembly A through the hydraulic torque converter B, and the locking and damping clutch assembly A is connected with the main shaft 14, and the main shaft 14 is connected with the main gearbox C and the auxiliary gearbox D at the same time; in the main gearbox C, the main shaft gear 1 7, the main shaft gear 2 26, the main shaft gear Three 24 and mai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com