Exhaust valve for hydraulic support

A technology of hydraulic support and exhaust valve, which is applied to mine roof supports, pillars/supports, mining equipment, etc., can solve the problems of inability to eliminate residual pressure and large risk factor, and achieve the effect of eliminating risk factor and residual pressure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0012] The exhaust valve for hydraulic support of the present invention, its preferred embodiment is:

[0013] It includes a joint, the joint is provided with a through hole in the axial direction, and a liquid discharge hole is provided in the radial direction. The rear part of the through hole is provided with a threaded screw rod. Sealed vice.

[0014] A limit pin is provided between the outer wall of the screw rod and the inner wall of the through hole.

[0015] The outer wall of the joint is provided with a U-shaped slot at the outlet of the drain hole.

[0016] Two φ1.2mm drain holes are radially opened on the joint, and the drain holes are perpendicular to the U-shaped slot.

[0017] The outer wall of the joint is provided with a sealing ring and a retaining ring at the front end.

[0018] The joint is made of QAL9-4 material, and the screw rod is made of high-quality stainless steel.

[0019] The exhaust valve for the hydraulic support of the present invention is u...

specific Embodiment

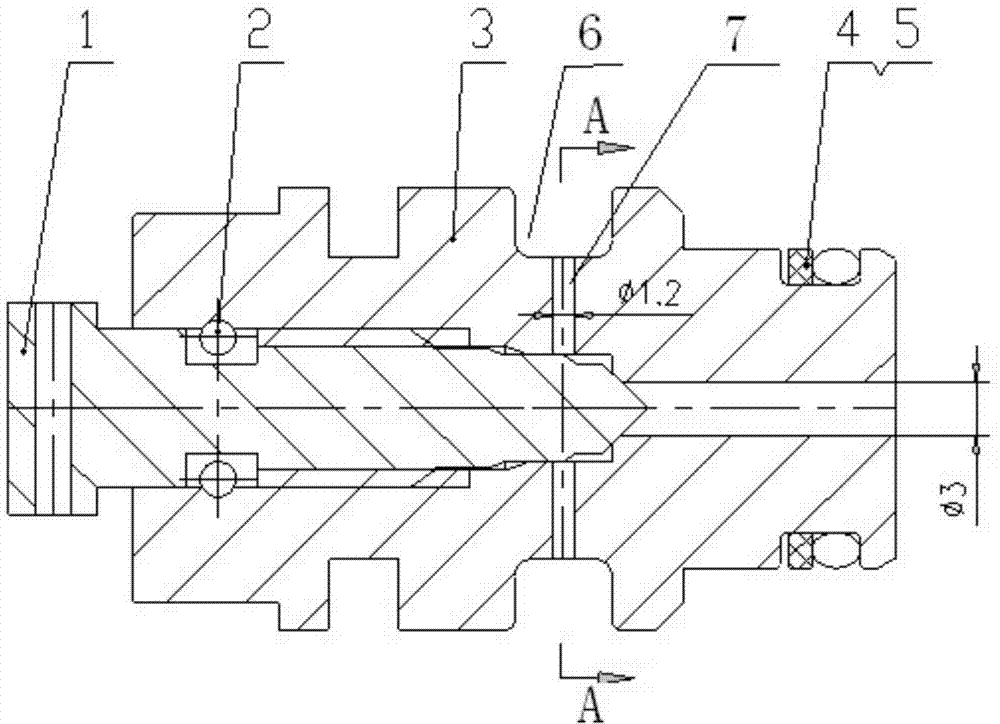

[0020] Such as figure 1 , figure 2 As shown, the air release valve includes a screw 1, a limit pin 2, a joint 3, a sealing ring 4 and a retaining ring 5; For sealing, put the two limit pins 2 into the joint 3, and assemble the sealing ring 4 and the retaining ring 5 on the joint 3. The rotary screw 1 is used to release the residual pressure, and at the same time, the joint 3 has a limit function, and the operation is simple and convenient.

[0021] The joint 3 adopts QAL9-4, which has a good sealing effect and a longer service life.

[0022] The positioning pin 2 prevents the screw rod 1 from being unscrewed too long, and prevents the impact from being too large.

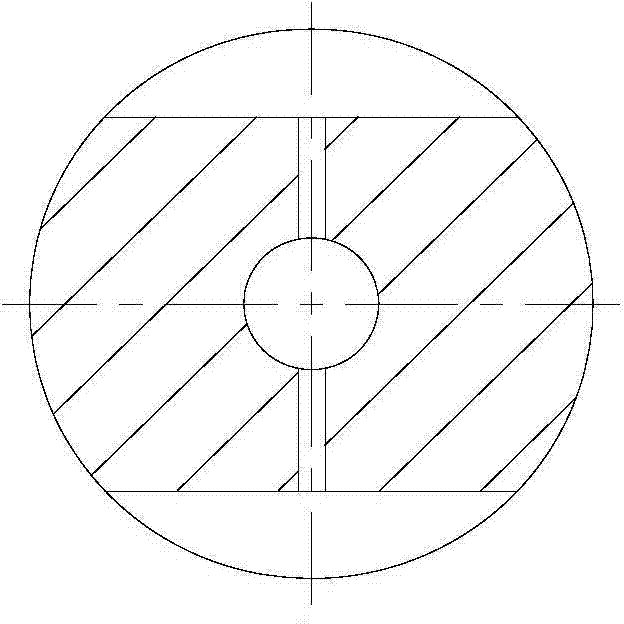

[0023] The U-shaped card on the connector 3 snaps in figure 2 The U-shaped groove on the outer wall of the connector shown prevents the connector from rotating.

[0024] Two φ1.2mm drain holes are opened on the joint 3, and the direction is perpendicular to the direction of the U-shaped slot.

[0025] The sc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com