Method and device for dynamically measuring hole deviation and toolface angle in condition of small hole deviation

A tool face angle, dynamic measurement technology, applied in the field of oil and natural gas drilling, can solve the problem of not being able to accurately reflect the real-time situation of well deviation and tool face, and achieve the goal of improving drilling efficiency, improving accuracy and precision, and reducing adverse effects. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below with reference to the accompanying drawings and specific embodiments. However, the described embodiments are only illustrative, and the present invention is not limited to the embodiments.

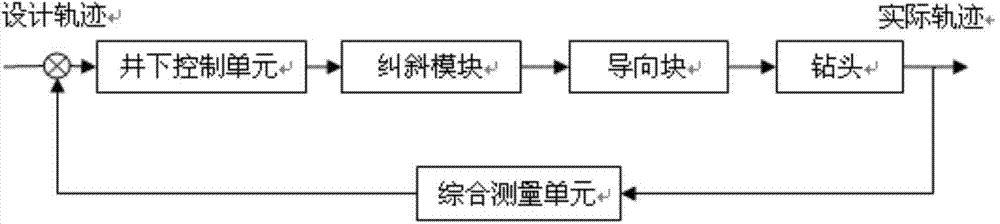

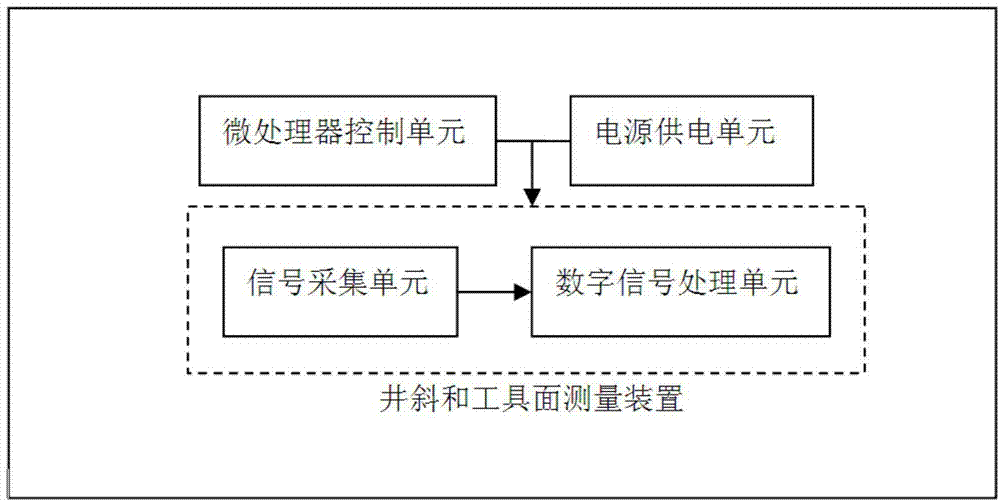

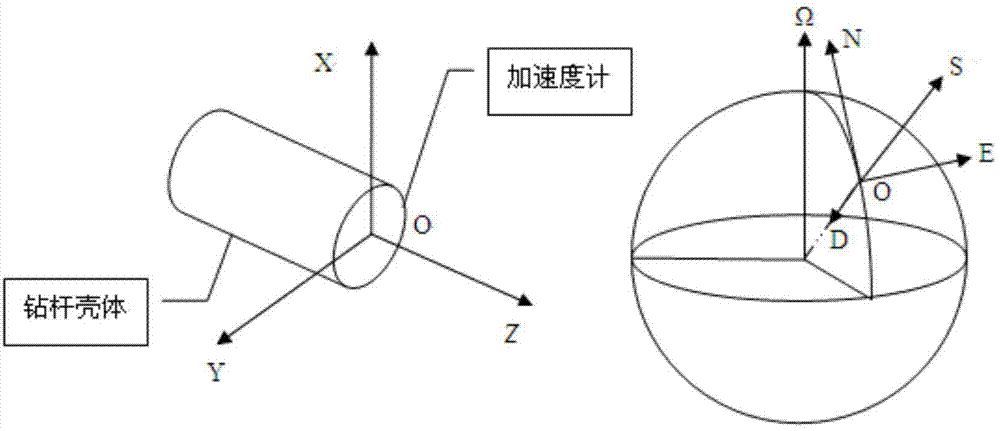

[0028] The invention provides a method and a device suitable for the dynamic measurement of the face angle of a well deviation tool under the condition of a small well deviation. The measurement method is realized by an automatic vertical drilling system. Such as figure 1 Shown is the conceptual schematic diagram of the automatic correction of the automatic vertical drilling system of the present invention. First, the inclination angle and the inclination azimuth angle are detected by the sensor as a comprehensive measurement unit, and then the downhole control unit is used to control the deviation, and the deviation correction module is used to correct the deviation, thereby controlling the action of the steering mechanism (block)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com