Pocket hooking mold

A mold and pocket technology, applied in material processing and textile fields, can solve problems such as low processing efficiency, uneven processing margin, and unguaranteed symmetry between left and right pockets, etc., and achieves the effect of convenient use and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] In order to further understand the content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are given below with reference to the accompanying drawings. It should be noted that this embodiment is descriptive, not restrictive, and cannot thereby limit the protection scope of the present invention.

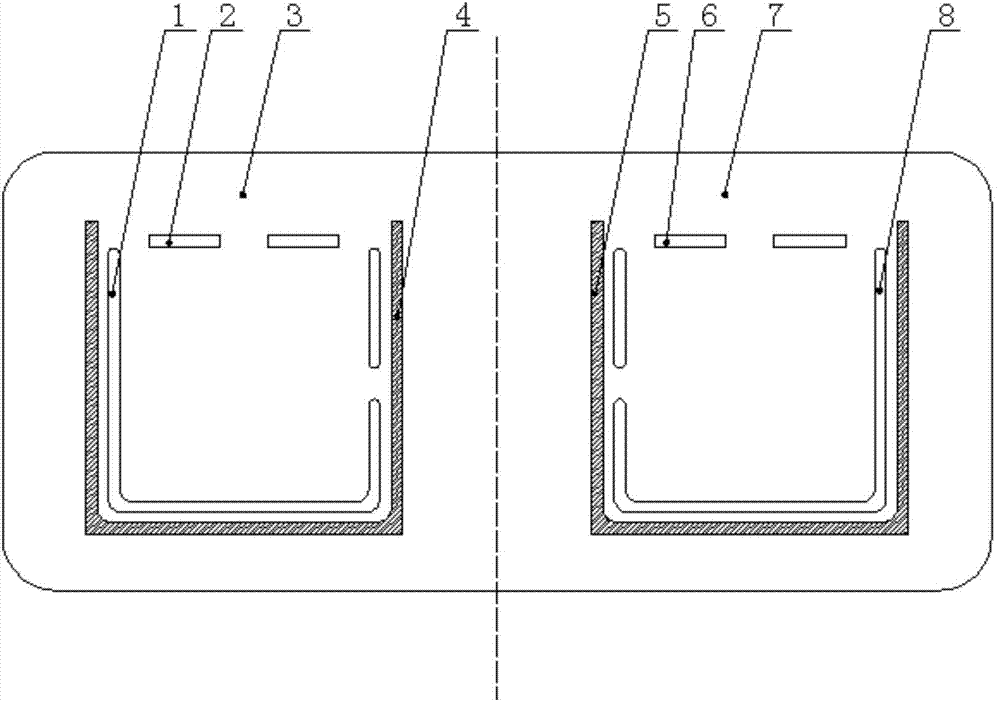

[0012] A hook pocket mold, consisting of a cover plate 3 and a backing plate 7, one side of the backing plate is hinged to the cover plate, and the cover plate and the backing plate are axially symmetrically provided with a cover plate hook line through groove 1 and a backing plate hook line The through groove 8, the cover plate hook line through groove and the outer periphery of the backing plate hook line through groove are respectively compounded with a cover plate anti-slip strip 4 and a backing plate anti-slip strip 5 .

[0013] Moreover, a cover plate elastic pressing block 2 is arranged on the upper part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com