Production device and method of molybdenum oxide nanoparticles

A nanoparticle and production device technology, applied in the direction of molybdenum oxide/molybdenum hydroxide, nanotechnology, nanotechnology, etc., can solve the problems of low efficiency, unstable product quality, complicated process, etc., and achieve no environmental pollution and easy large-scale The effect of increasing production and improving gasification conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

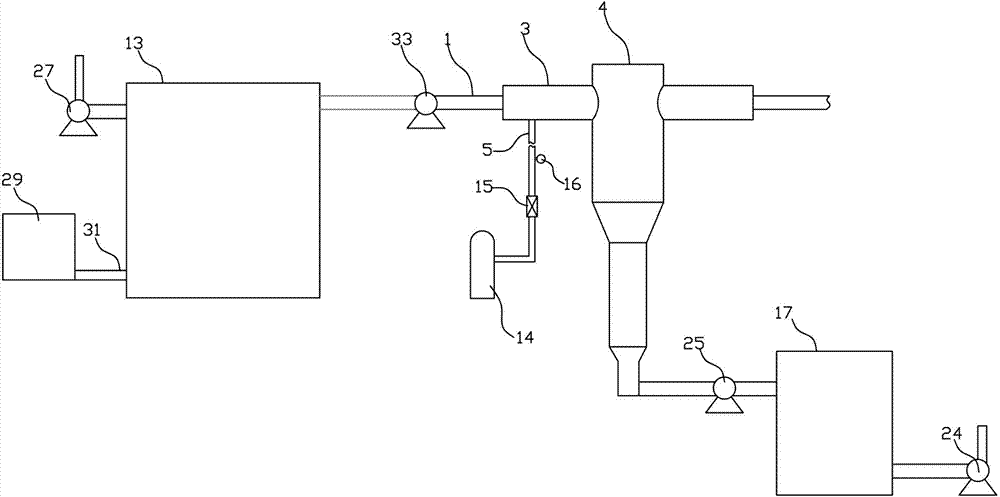

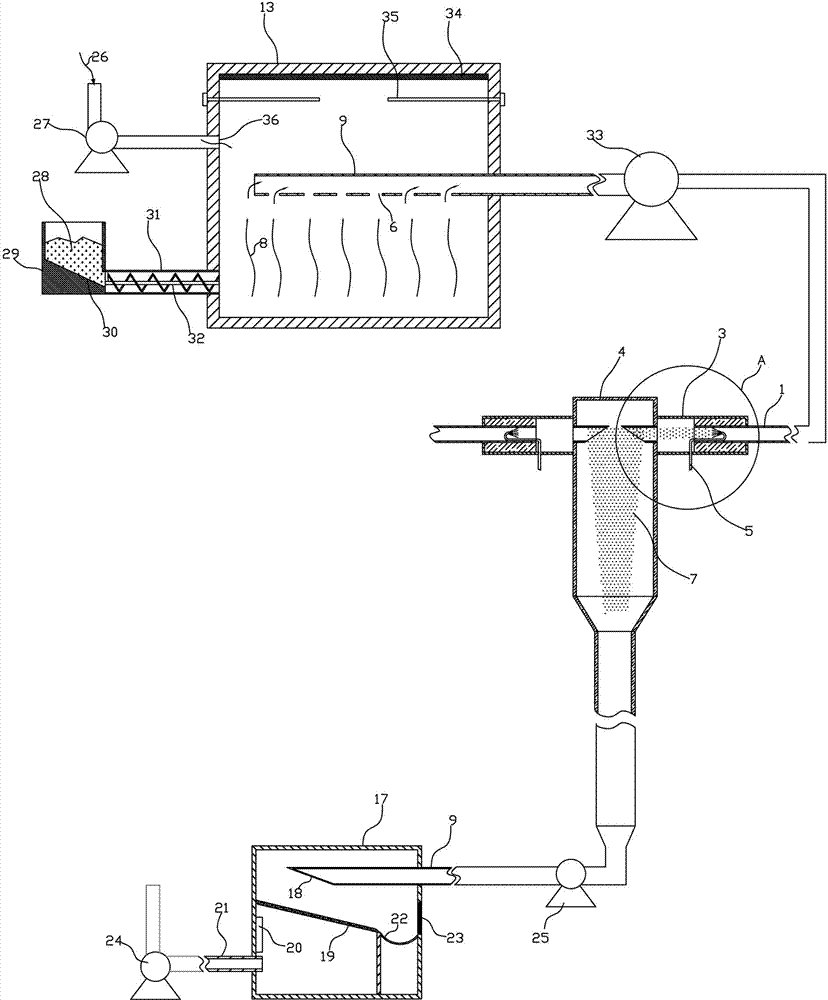

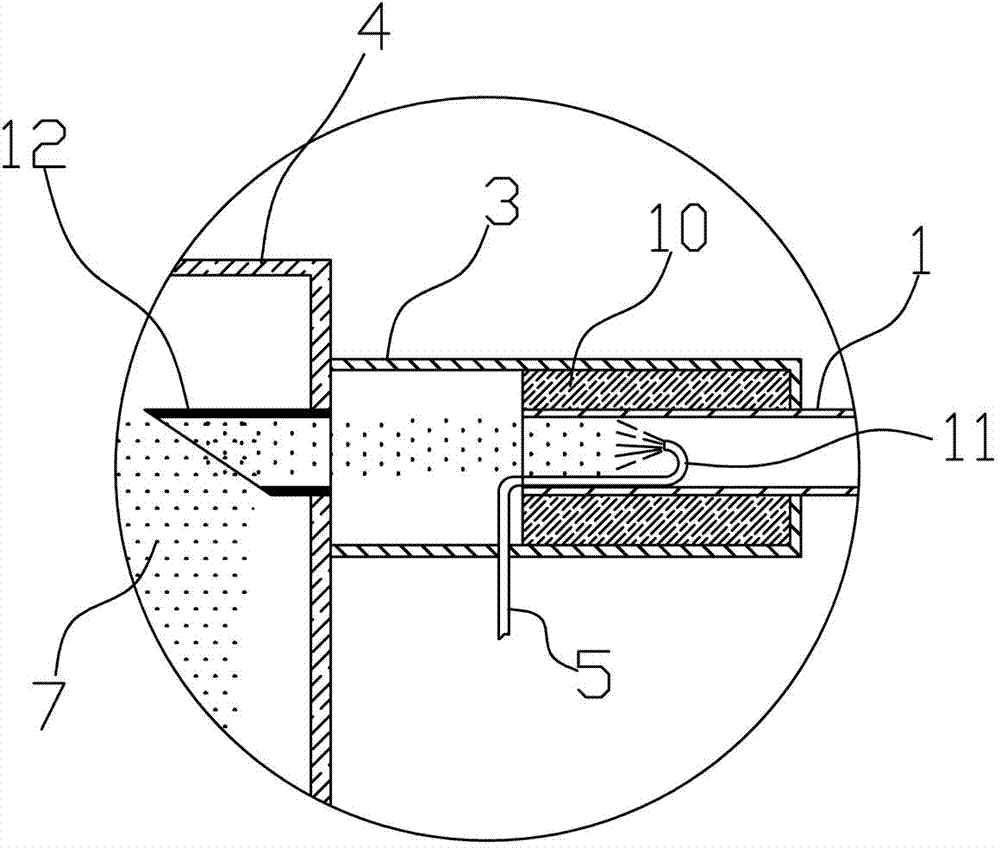

[0046] Embodiment 1: A kind of molybdenum oxide nanoparticle production device, and production method, see figure 1 , figure 2 , image 3 The device includes a gasification unit for gasifying the precursor material of molybdenum oxide nanoparticles, a quenching unit for quenching the gasified molybdenum oxide nanoparticles, and collecting molybdenum oxide nanoparticles Finished product collection unit.

[0047] The gasification unit includes a gasification furnace, and the gasification furnace includes a furnace body 13 with a closed cavity inside, and four electric heating elements correspondingly arranged in the furnace body for raising the temperature of the furnace body. body 35; the gasification unit also includes a feeding mechanism for delivering precursor materials to the furnace body; further, an air inlet 36 communicating with the outside is provided on the upper side wall of the furnace body, and at the same time, The gasification furnace also includes a second ...

Embodiment 2

[0052] Embodiment 2: the method for producing molybdenum oxide nanoparticles using the above-mentioned molybdenum oxide nanoparticle production device, see figure 1 , figure 2 , image 3 ; it includes the following steps:

[0053] a. Raise the temperature in the gasifier to between 1150°C and 1210°C;

[0054] b. turn on the second blower 27, negative pressure blower 33, blower 25, exhaust fan 24 in turn;

[0055] c. Open the valve so that the quenching liquid is ejected from the end outlet of the quenching liquid pipe;

[0056] d. Sending the precursor material of molybdenum oxide nanoparticles into the gasifier;

[0057]Before performing step (d), the temperature in the gasifier should be kept between 1150 ° C and 1210 ° C for 8-10 minutes; at the same time, the end outlet of the quenching liquid pipe should be sprayed out when performing step (c) The pressure of the quenching liquid is kept at 4.0-5.3Pa; and the suction capacity of the exhaust fan 24 is kept at 1000-12...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com