Elevator traction machine and method for improving comprehensive performance thereof

A technology of elevator traction machine and comprehensive performance, which is applied in the field of traction machine to improve the performance of traction machine, and can solve the problems of unsatisfactory fastening stability of magnetic steel, easy rotation of stator coil, increase of ring gear material, etc., to achieve Prevents radial shedding, reduces processing cost, and improves strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the examples, but not as a basis for limiting the present invention.

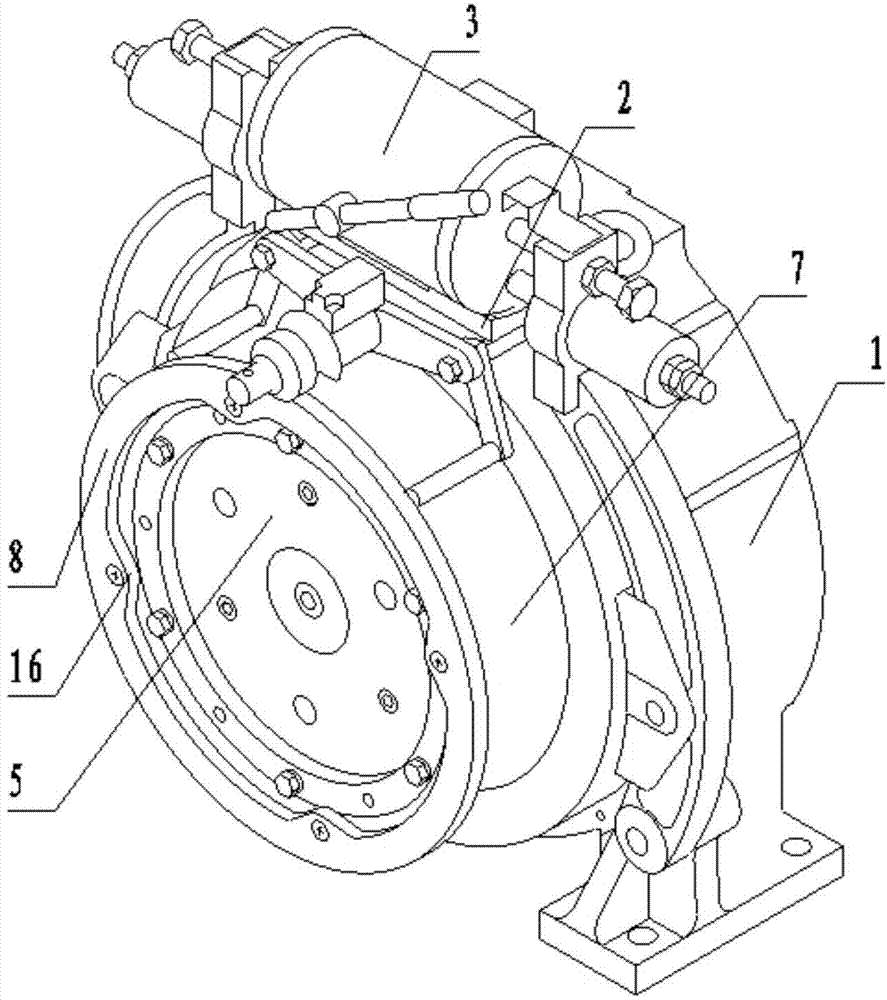

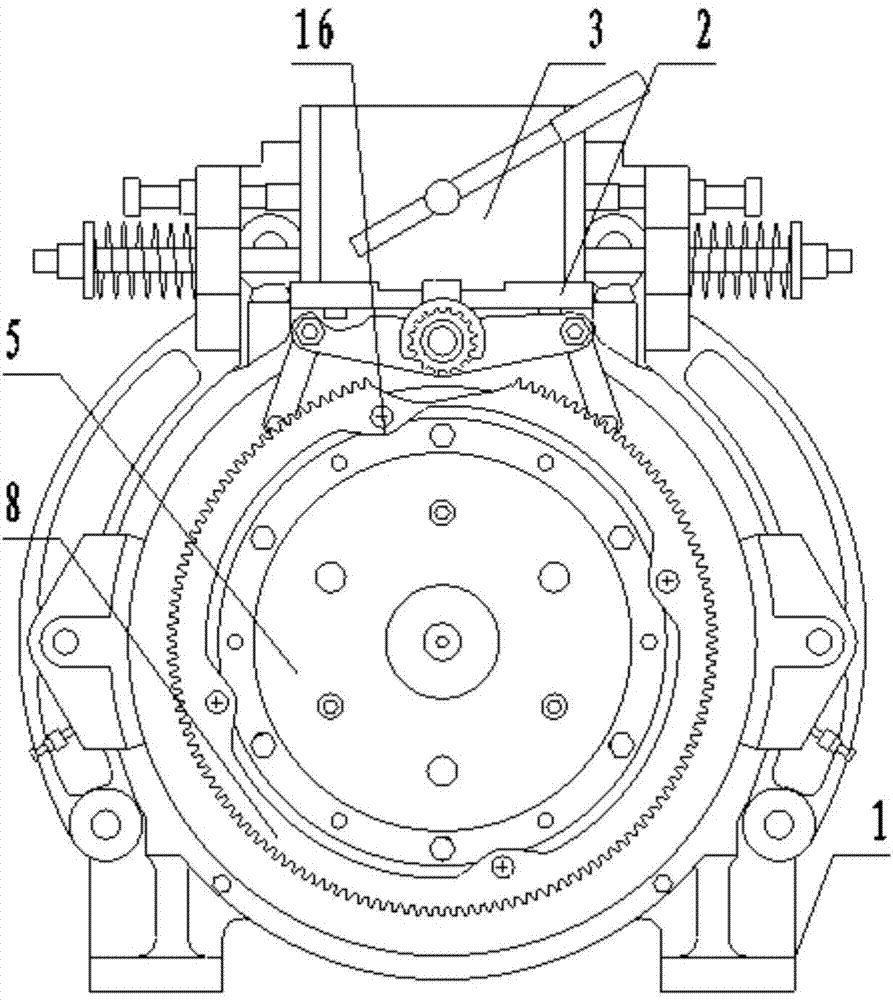

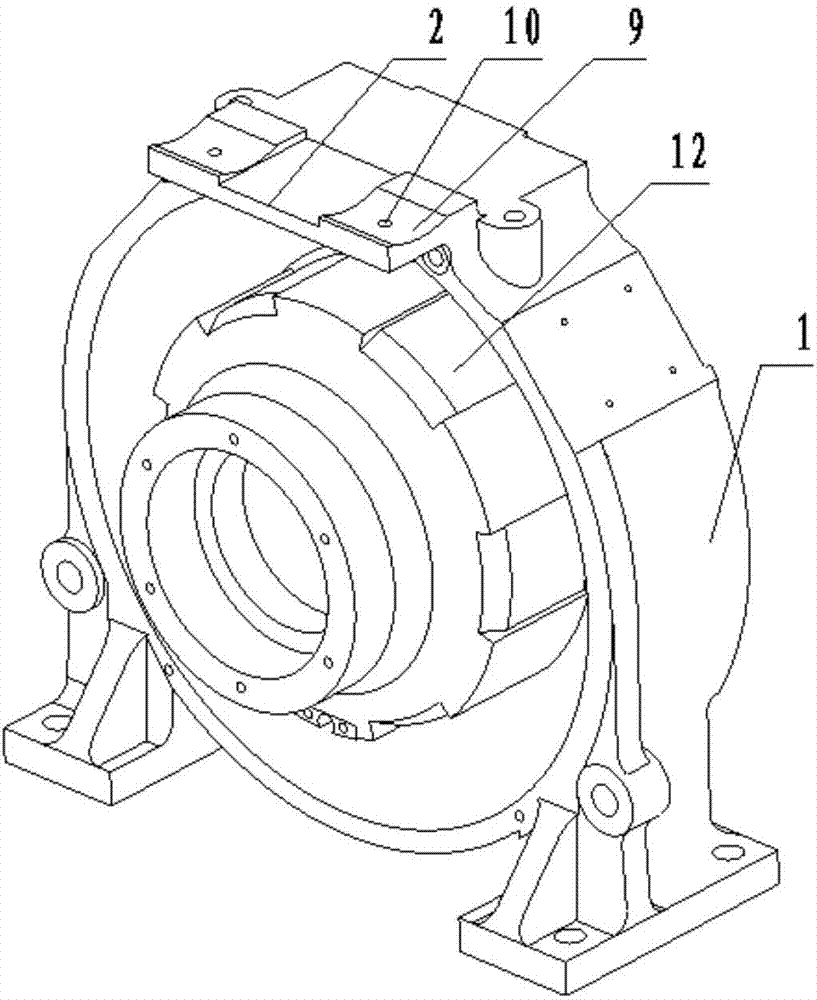

[0025] Example. Methods to improve the overall performance of the elevator traction machine, such as Figures 1 to 7 As shown, the connecting seat 2 is formed on the machine base 1 by bending and forming to strengthen the strength of the connecting seat 2; an arc-shaped installation groove 9 is set on the connecting seat 2 to facilitate the installation and fixing of the brake 3; in the machine base 1 Set the groove 12 and the positioning pin 11 to limit the rotation of the stator coil 4 and reduce the finishing area; set the boss 13 and the magnetic steel pressing piece 15 on the rotor yoke 5 to fasten the position of the magnetic steel 6; A notch 17 and a lug 16 are arranged on the top, the lug 16 is fixed on the side of the traction sheave 7 by screws, the area of the lug 16 is reduced, and the fixing of the ring gear 8 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com