A kind of environment-friendly thermoplastic elastomer foam floor mat material and preparation method thereof

A thermoplastic elastomer and floor mat technology, used in the field of floor mat materials, can solve the problems of TPE's heat resistance is not as good as rubber, the decline in physical properties is large, and the scope of application is limited. Good smoke suppression effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] A kind of preparation method of environment-friendly thermoplastic elastomer foaming mat material, it comprises the following steps:

[0043] 1) Pour the components of the TPU film layer into the calender molding machine and calender to obtain the TPU film layer;

[0044] 2) Pour the components of the TPE foam layer into a calender molding machine for calendering to obtain a TPE foam layer;

[0045] 3) Preheat the reinforced fiber mesh under the heating roller to remove the impurities attached to the surface, then send it to the coating machine through the sending device, dip it in the PU adhesive layer coating solution, and send it to the scraper device to control Paste the amount, and then send it to the oven for drying and plasticization to obtain a first-class reinforced fiber mesh cloth with PU adhesive layers on the surface and bottom surface;

[0046] 4) Preheat the surface and bottom surface of the primary reinforced fiber mesh on the preheating roller, then he...

Embodiment 1

[0049] A kind of preparation method of environment-friendly thermoplastic elastomer foaming mat material, it comprises the following steps:

[0050] 1) Pour the components of the TPU film layer into the calender molding machine and calender to obtain the TPU film layer;

[0051] Described TPU film layer comprises the component of following weight part:

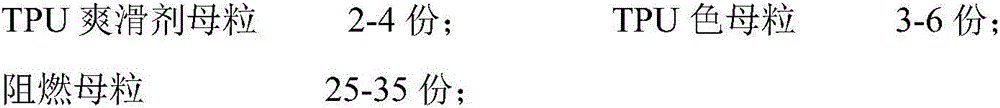

[0052]

[0053] 2) Pour the components of the TPE foam layer into a calender molding machine for calendering to obtain a TPE foam layer;

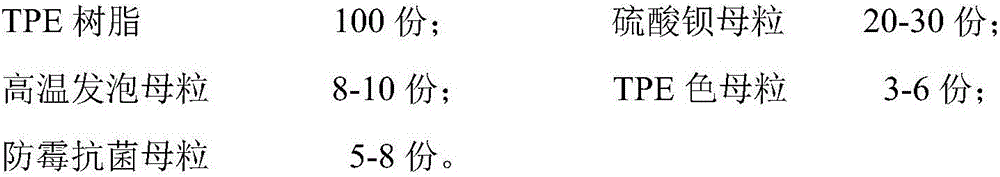

[0054] The TPE foam layer includes the following components by weight:

[0055]

[0056] The high-temperature foam masterbatch includes the following components by weight:

[0057]

[0058] 3) Preheat the reinforced fiber mesh under the heating roller to remove the impurities attached to the surface, then send it to the coating machine through the sending device, dip it in the PU adhesive layer coating solution, and send it to the scraper device to control Paste the amount, and ...

Embodiment 2

[0062] A kind of preparation method of environment-friendly thermoplastic elastomer foaming mat material, it comprises the following steps:

[0063] 1) Pour the components of the TPU film layer into the calender molding machine and calender to obtain the TPU film layer;

[0064] Described TPU film layer comprises the component of following weight part:

[0065]

[0066] 2) Pour the components of the TPE foam layer into a calender molding machine for calendering to obtain a TPE foam layer;

[0067] The TPE foam layer includes the following components by weight:

[0068]

[0069] The high-temperature foam masterbatch includes the following components by weight:

[0070]

[0071] 3) Preheat the reinforced fiber mesh under the heating roller to remove the impurities attached to the surface, then send it to the coating machine through the sending device, dip it in the PU adhesive layer coating solution, and send it to the scraper device to control Paste the amount, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com