Preparation of graphene oxide and nanosized silica composite filler reinforced binder for dentistry

A nano-silica, composite filler technology, applied in the direction of dental preparations, dentistry, dental prosthesis, etc., to achieve the effect of improving bonding strength and good dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

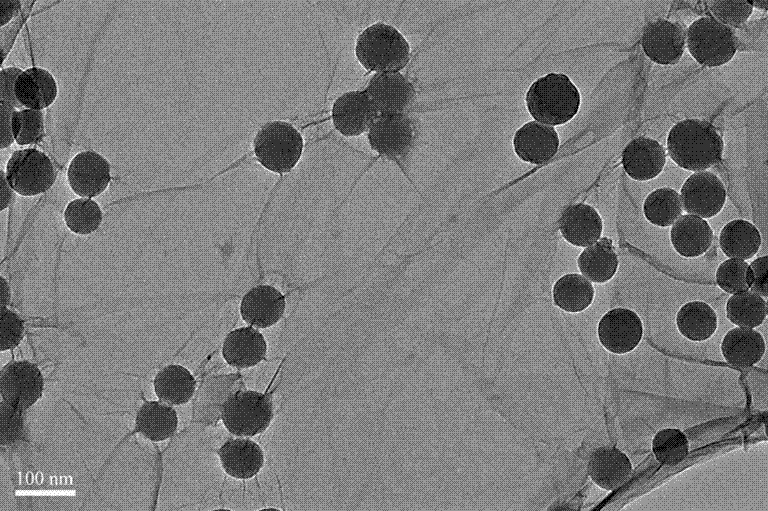

[0024] Preparation of graphene oxide and nano silicon oxide composites: prepare graphene oxide according to the Hummers method, prepare an aqueous solution with a concentration of 0.2 mg / ml graphene oxide, prepare nano silicon oxide according to the stober method, and perform APTES modification to obtain APTES modified nano Silicon oxide, and then prepare an aqueous solution of APTES-modified nano-silica with a concentration of 20mg / ml. The above two solutions are ultrasonically dispersed, and then the two solutions are stirred and mixed evenly according to the volume ratio of 1:1, and the precipitation is removed overnight. supernatant, and then the precipitate was freeze-dried for 48 hours to obtain graphene oxide and nano-silicon oxide composites, as attached figure 1 shown;

Embodiment 2

[0026] Surface modification of graphene oxide and nano-silicon oxide: Weigh 1g of graphene oxide and nano-silicon oxide compound and dissolve it in 200ml of water, stir first and then sonicate to disperse evenly, add 10ml HEMA, SPAN80 2g, potassium persulfate 0.05g in turn , toluene 100ml, stirring to form a microemulsion, feeding N in the reaction process 2 , reflux, and heated to 60 ° C for 3 hours, then centrifuged, vacuum-dried at room temperature, washed with ethanol and centrifuged three times to obtain pHEMA-modified graphene oxide and nano-silicon oxide composite materials;

Embodiment 3

[0028] According to the proportion of components: graphene oxide and nano-silica composite filler 2%, TEGDMA38%, BisGMA54%, HEMA3%, CQ0.5%, DMAEMA0.5%, 4-META2%, modify the pHEMA obtained in Example 2 The graphene oxide and nano-silicon oxide composite materials were added to TEGDMA, stirred magnetically at room temperature for 1 hour, and then used a cell disruptor to perform further ultrasonic treatment in an ice-water bath to disperse the composite filler in TEGDMA to obtain solution A; then Heat solution A to 60°C, add BisGMA, stir magnetically to obtain mixed solution B; cool mixed solution B to room temperature, add HEMA, CQ, DMAEMA, 4-META to solution B in turn, magnetically stir and then ultrasonically disperse to obtain graphite oxide Oxygen and nano-silica composite filler reinforced dental adhesive;

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com